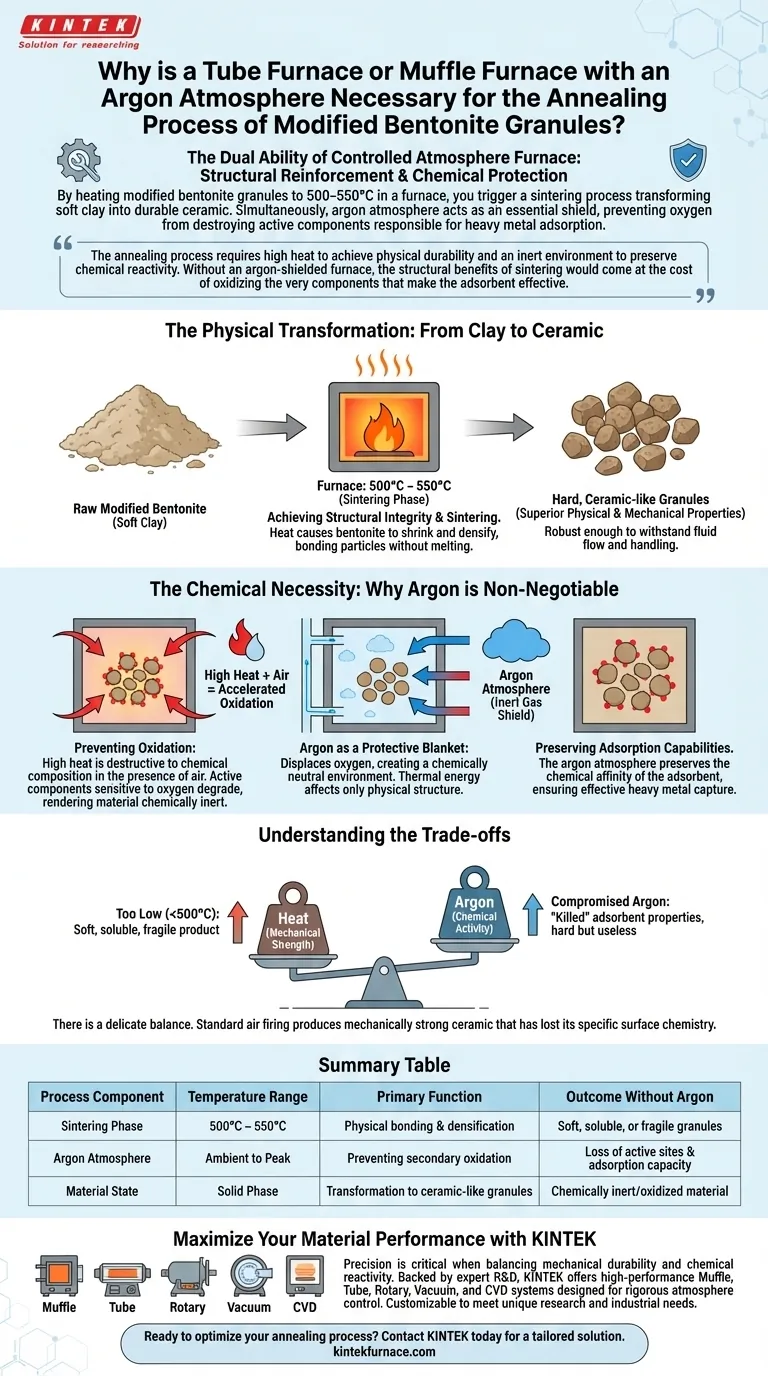

The necessity of a controlled atmosphere furnace lies in its dual ability to structurally reinforce the material while chemically protecting it. By heating modified bentonite granules to 500–550°C in a tube or muffle furnace, you trigger a sintering process that transforms soft clay into durable ceramic. Simultaneously, the argon atmosphere acts as an essential shield, preventing oxygen from destroying the active components responsible for heavy metal adsorption.

The annealing process requires high heat to achieve physical durability and an inert environment to preserve chemical reactivity. Without an argon-shielded furnace, the structural benefits of sintering would come at the cost of oxidizing the very components that make the adsorbent effective.

The Physical Transformation: From Clay to Ceramic

Achieving Structural Integrity

Modified bentonite in its raw form may lack the mechanical strength required for industrial applications.

To correct this, the furnace must reach temperatures between 500°C and 550°C. This specific heat range initiates sintering, a process where the particles bond together without melting.

Sintering and Shrinkage

During this thermal treatment, the granules undergo significant physical changes.

The heat causes the bentonite to shrink and densify. This transformation converts the material into hard, ceramic-like granules. These granules possess superior physical and mechanical properties, making them robust enough to withstand fluid flow and handling without breaking down.

The Chemical Necessity: Why Argon is Non-Negotiable

Preventing Oxidation

While high heat is necessary for structure, it is destructive to chemical composition in the presence of air.

The modified bentonite contains active components that are sensitive to oxygen at high temperatures. Without protection, the heat would accelerate oxidation, degrading these components and rendering the material chemically inert.

The Role of Inert Gas

Argon acts as a protective blanket.

By displacing oxygen within the furnace tube or muffle, argon creates a chemically neutral environment. This ensures that the thermal energy affects only the physical structure (sintering) and does not trigger unwanted chemical reactions like secondary oxidation.

Preserving Adsorption Capabilities

The ultimate goal of modified bentonite is often to remove contaminants, such as heavy metal ions.

The argon atmosphere preserves the chemical affinity of the adsorbent. By preventing the degradation of active sites during heating, the final product retains its ability to effectively target and capture heavy metals.

Understanding the Trade-offs

Heat vs. Chemical Activity

There is a delicate balance between mechanical strength and chemical performance.

If the temperature is too low (below 500°C), the granules may not sinter fully, resulting in a product that is too soft or soluble. Conversely, if the argon atmosphere is compromised, the high heat will "kill" the adsorbent properties, resulting in a hard but useless granule.

The Cost of Complexity

Using an argon atmosphere adds complexity and cost compared to standard air firing.

However, this is not an optional luxury. Standard air firing would likely produce a mechanically strong ceramic that has lost its specific surface chemistry, negating the purpose of the modification.

Making the Right Choice for Your Process

To ensure the success of your annealing process, prioritize the following parameters:

- If your primary focus is mechanical durability: Ensure your furnace creates a stable heating profile between 500°C and 550°C to guarantee complete sintering and ceramic transformation.

- If your primary focus is adsorption efficiency: Verify the integrity of the argon seal and flow rate to ensure zero oxygen ingress during the high-temperature phase, protecting the active sites.

Success depends on using the furnace to harden the body of the granule while using argon to protect its chemical soul.

Summary Table:

| Process Component | Temperature Range | Primary Function | Outcome Without Argon |

|---|---|---|---|

| Sintering Phase | 500°C – 550°C | Physical bonding & densification | Soft, soluble, or fragile granules |

| Argon Atmosphere | Ambient to Peak | Preventing secondary oxidation | Loss of active sites & adsorption capacity |

| Material State | Solid Phase | Transformation to ceramic-like granules | Chemically inert/oxidized material |

Maximize Your Material Performance with KINTEK

Precision is critical when balancing mechanical durability and chemical reactivity. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to maintain rigorous atmosphere control for sensitive processes like bentonite annealing.

Whether you need custom gas flow configurations or precise temperature uniformity to protect your active components, our lab high-temperature furnaces are fully customizable to meet your unique research and industrial needs.

Ready to optimize your annealing process? Contact KINTEK today for a tailored solution.

Visual Guide

References

- Bakytgul Kussainova, Aidana Bazarkhankyzy. Physico-Chemical Properties of Granular Sorbents Based on Natural Bentonite Modified by Polyhydroxocations of Aluminum and Iron (III) by Co-Precipitation. DOI: 10.3390/molecules30010195

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How is a tube furnace utilized to construct DTB sites for Co/Co0.85Se@NC? Mastering Phase Engineering

- What is the function of a fast-response photoelectric sensor system? Precision Ignition Timing in Tube Furnaces

- What role does a high-temperature tube furnace play in lignin carbonization? Precision Heating for Porous Carbon

- What are the types of Tube Furnaces based on orientation? Horizontal vs. Vertical for Optimal Thermal Processing

- What is a tubular heater used for? Prevent Frost and Damp with Low-Cost Maintenance Heat

- What critical reaction conditions does a tube furnace provide during the synthesis of SFC5 materials?

- What is the necessity of the 500 °C hydrogen environment provided by a tube reduction furnace? Master Catalyst Activation

- What are the temperature control requirements for SiC@SiO2 in-situ oxidation? Achieve Precise 1100°C Thermal Stability