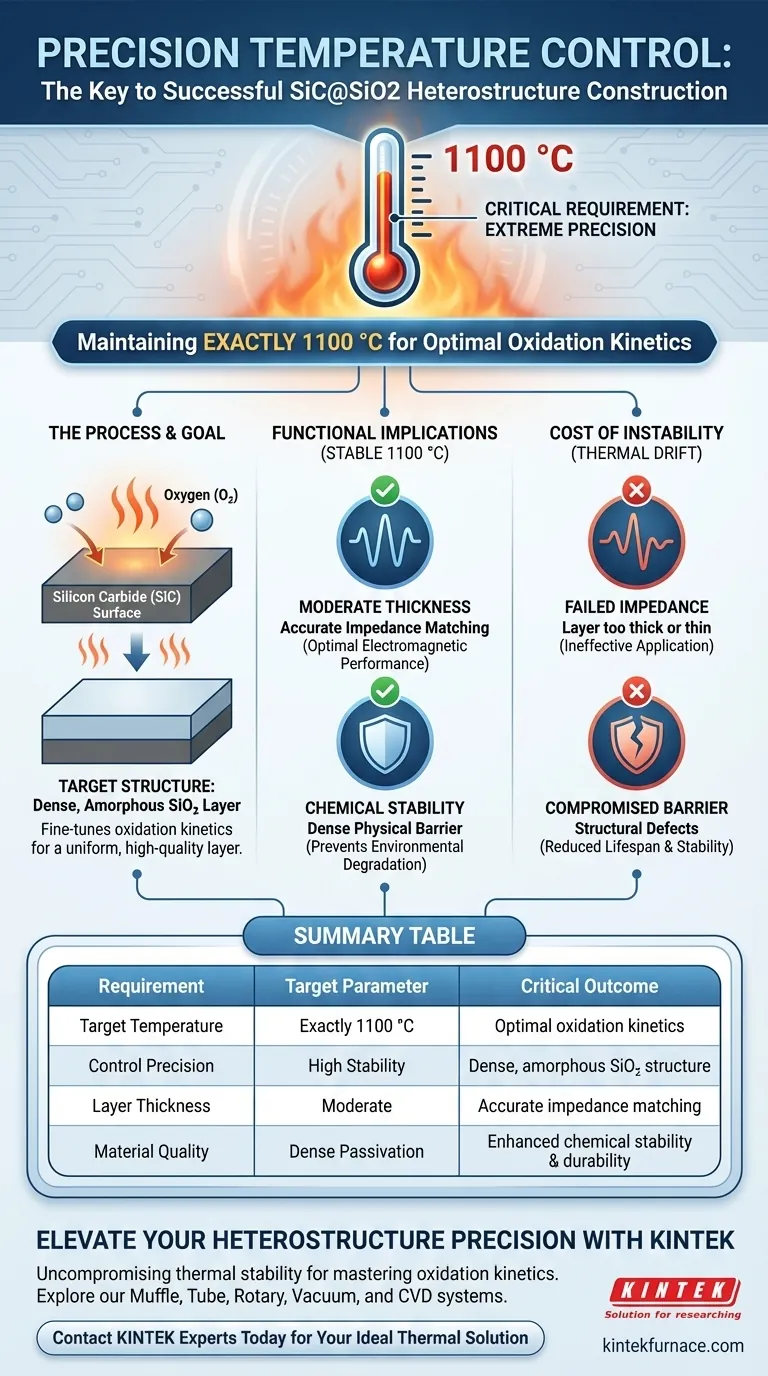

The critical requirement for heating equipment during the in-situ oxidation stage is the capability to maintain extreme temperature control precision at exactly 1100 °C. This specific thermal regulation is not merely about reaching a high temperature; it is about sustaining a highly stable environment to fine-tune the oxidation kinetics on the Silicon Carbide (SiC) surface. Without this precision, the formation of the necessary heterostructure features becomes impossible.

The success of SiC@SiO2 heterostructure construction depends on stabilizing reaction kinetics at 1100 °C. Precise thermal control is the only mechanism that ensures the formation of a dense, amorphous SiO2 layer with the moderate thickness required for optimal performance.

The Role of Precision in Oxidation Kinetics

Controlling Reaction Rates

At 1100 °C, the chemical interaction between Silicon Carbide and oxygen is highly sensitive. The heating equipment must offer precision control to fine-tune the oxidation kinetics.

This ensures the reaction proceeds at a predictable and constant rate. Any fluctuation in temperature will alter the speed of oxidation, leading to inconsistent material properties.

Forming the Target Structure

The ultimate goal of this thermal stage is to create a dense, amorphous SiO2 passivation layer.

This specific structural phase—dense and amorphous rather than porous or crystalline—can only be achieved if the temperature remains strictly regulated throughout the process.

Functional Implications of Thermal Control

Achieving Moderate Thickness

The thickness of the SiO2 layer is directly correlated to the temperature and duration of the oxidation.

The heating equipment must maintain stability to produce a layer of moderate thickness. This specific thickness is essential for adjusting impedance matching, a critical factor in the material's electromagnetic performance.

Ensuring Chemical Stability

The SiO2 layer serves as a physical barrier for the underlying SiC.

By maintaining precise heat, the equipment ensures the layer is sufficiently dense to provide robust chemical stability. This prevents environmental degradation of the core material.

The Cost of Thermal Instability

Risks to Impedance Matching

If the heating equipment lacks precision, the oxidation kinetics will drift.

This results in a passivation layer that is either too thick or too thin. Consequently, the impedance matching will fail, rendering the heterostructure ineffective for its intended application.

Compromised Barrier Integrity

Temperature fluctuations during the in-situ stage can lead to structural defects in the SiO2 layer.

A layer formed under unstable thermal conditions may lack the necessary density. This compromises its ability to act as a reliable physical barrier, reducing the overall lifespan and stability of the component.

Optimizing Your Heating Strategy

To ensure the successful construction of SiC@SiO2 heterostructures, select heating equipment based on the specific performance metrics you need to achieve.

- If your primary focus is Electromagnetic Performance: Prioritize equipment with minimal thermal drift to ensure the precise "moderate thickness" required for accurate impedance matching.

- If your primary focus is Long-Term Durability: Ensure the system can hold 1100 °C without fluctuation to guarantee the formation of a dense, amorphous barrier for maximum chemical stability.

The quality of your final heterostructure is ultimately defined by the stability of your thermal environment.

Summary Table:

| Requirement | Target Parameter | Critical Outcome |

|---|---|---|

| Target Temperature | Exactly 1100 °C | Optimal oxidation kinetics |

| Control Precision | High Stability | Dense, amorphous SiO2 structure |

| Layer Thickness | Moderate | Accurate impedance matching |

| Material Quality | Dense Passivation | Enhanced chemical stability & durability |

Elevate Your Heterostructure Precision with KINTEK

Successful SiC@SiO2 construction demands uncompromising thermal stability at 1100°C. KINTEK provides the advanced heating solutions required to master oxidation kinetics and achieve perfect impedance matching.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are developing high-performance electromagnetic materials or robust semiconductor components, our lab high-temp furnaces are fully customizable to meet your unique research needs.

Ensure consistent results and superior material integrity—Contact KINTEK experts today to find your ideal thermal solution.

Visual Guide

References

- Limeng Song, Rui Zhang. Heterointerface‐Engineered SiC@SiO <sub>2</sub> @C Nanofibers for Simultaneous Microwave Absorption and Corrosion Resistance. DOI: 10.1002/advs.202509071

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How does a vertical tube furnace facilitate the simulation of the industrial sintering process for iron ores?

- How does a multi-tube pyrolysis furnace achieve precise temperature control? Advanced Hardware & PID Logic Explained

- How does the quartz tube furnace minimize heat loss? Double Insulation for Energy Efficiency

- How does a vertical tube furnace ensure effective hydrogen reduction reactions? Optimize Rare Earth Tailing Processing

- What are the advantages of combining an online mass spectrometer with a fixed-bed reactor? Boost Kinetic Precision

- What role does the calcination process in a high vacuum tube furnace play in the formation of Ce1-xTixO2-δ supports?

- What is a vertical tube furnace? Leverage Gravity for Superior Material Processing

- What is the role of a vacuum tube furnace in the carbonization of biomass? Achieve Precision in Porous Carbon Synthesis