A nitrogen atmosphere acts as a critical protective and transformative medium during the synthesis of Co-HCC nanoparticles. By maintaining an inert environment within the high-temperature tube furnace, nitrogen prevents the oxidation of metallic cobalt while simultaneously driving the chemical reduction of organic ligands. Furthermore, this specific atmosphere enables the evaporation of volatile components, which is the physical mechanism responsible for creating the material's unique hollow structure.

The Core Takeaway Nitrogen does more than just protect the sample; it fundamentally alters the reaction pathway at 800 °C. By excluding oxygen, the furnace environment favors carbonization over combustion, allowing for the precise removal of zinc to form a hollow cage while locking metallic cobalt into a stable, graphitized carbon framework.

The Role of Nitrogen in Chemical Transformation

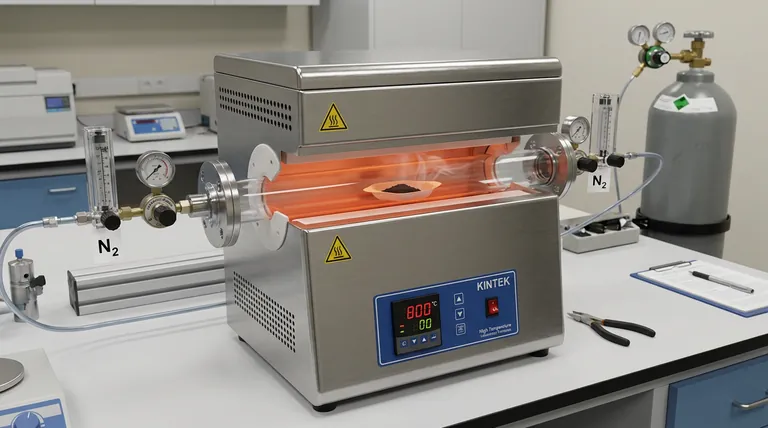

The introduction of nitrogen into the tube furnace creates specific chemical conditions necessary for the successful carbonization of Metal-Organic Frameworks (MOFs).

Preventing Metallic Oxidation

The primary function of the nitrogen atmosphere is to create a non-reactive, oxygen-deficient environment.

Without this barrier, the high temperatures required for synthesis would cause the metallic cobalt to react instantly with oxygen. Nitrogen ensures that the cobalt remains in its metallic state rather than degrading into cobalt oxides, which would fundamentally alter the magnetic and electronic properties of the final nanoparticle.

Facilitating Ligand Reduction

Beyond simple protection, nitrogen actively promotes the reduction of organic ligands.

In an oxidizing atmosphere, organic components would burn off as CO2. However, in the inert nitrogen atmosphere at 800 °C, these ligands undergo pyrolysis. This process converts the organic material into a highly graphitized carbon framework, which provides conductivity and structural stability to the nanoparticle.

Structural Engineering via Atmosphere Control

The nitrogen atmosphere is not just about chemistry; it is also a tool for physical structural engineering, specifically regarding the "Hollow Carbon Cage" (HCC) aspect of the material.

Controlled Evaporation of Zinc

The synthesis relies on the presence of zinc in the precursor material. The nitrogen environment allows for the selective evaporation of zinc.

Zinc has a relatively low boiling point compared to cobalt. At the synthesis temperature of 800 °C, the zinc vaporizes and exits the material. Because the atmosphere is inert, this evaporation happens cleanly without forming zinc oxides that could trap the metal within the structure.

Formation of the Hollow Cage

The departure of the zinc leaves behind a void, creating the hollow carbon cage structure.

This "sacrificial template" strategy relies entirely on the atmosphere allowing the zinc to leave while the carbon shell hardens around it. The result is a unique architecture: a hollow interior housing the cobalt, surrounded by a robust carbon shell.

Understanding the Trade-offs

While nitrogen is essential for this specific synthesis, relying on an inert atmosphere introduces specific variables that must be managed to avoid failure.

Sensitivity to Gas Purity

The success of the process hinges on high-purity nitrogen.

Even trace amounts of oxygen can disrupt the formation of the graphitized carbon shell or lead to partial oxidation of the cobalt. Unlike vacuum systems, flow-through nitrogen systems must be rigorously checked for leaks or low-quality gas sources that could introduce impurities.

Thermal Dynamics and Flow Rates

The flow of nitrogen gas can impact the temperature uniformity within the tube.

If the flow rate is too high, it may cool the sample surface, preventing it from reaching the critical 800 °C required for zinc evaporation. Conversely, if the flow is too low, the evaporated zinc and volatile organics may not be flushed out efficiently, potentially re-depositing on the sample.

Making the Right Choice for Your Goal

To ensure the successful preparation of Co-HCC nanoparticles, align your furnace parameters with your specific structural goals.

- If your primary focus is Structural Definition (Hollow Cage): Ensure your heating profile holds strictly at 800 °C under constant nitrogen flow to guarantee complete zinc evaporation.

- If your primary focus is Chemical Purity (Metallic Cobalt): Verify that your nitrogen source is 99.9% pure or higher to prevent the formation of insulating oxide layers on the cobalt surface.

Success in this synthesis depends on treating the nitrogen atmosphere not just as a safety feature, but as an active reagent in the formation of the nanoparticle's architecture.

Summary Table:

| Function | Mechanism | Impact on Co-HCC Nanoparticles |

|---|---|---|

| Inert Shielding | Prevents metallic oxidation | Preserves cobalt's magnetic and electronic properties |

| Carbonization | Pyrolysis of organic ligands | Creates a stable, conductive graphitized carbon framework |

| Structural Voids | Facilitates zinc evaporation | Forms the signature "Hollow Carbon Cage" (HCC) architecture |

| Thermal Control | Regulated gas flow | Ensures temperature uniformity for clean volatile removal |

Elevate Your Nanomaterial Synthesis with KINTEK

Precision is non-negotiable when engineering complex structures like Co-HCC nanoparticles. KINTEK provides high-performance Tube, Vacuum, CVD, and Muffle furnace systems specifically designed to maintain the rigorous atmosphere purity and thermal stability your research demands.

Backed by expert R&D and manufacturing, our systems are fully customizable to handle specific gas flow dynamics and high-purity nitrogen environments, ensuring consistent results in every carbonization cycle.

Ready to optimize your lab's high-temperature processes? Contact us today to find the perfect furnace for your unique material needs.

References

- Tian Mai, Ming‐Guo Ma. Hollow Metal–Organic Framework/MXene/Nanocellulose Composite Films for Giga/Terahertz Electromagnetic Shielding and Photothermal Conversion. DOI: 10.1007/s40820-024-01386-5

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What are the primary applications of tube furnaces? Unlock Precision in High-Temperature Processing

- What are the common features of the heating chamber in a horizontal tube furnace? Achieve Precise Thermal Control for Your Lab

- What role does an Electrically Heated Drop Tube Furnace (DTF) play in iron powder experiments? Boost Your Research Now!

- Why is a high-precision programmable tube furnace required for N-doped TiO2@C composites? Expert Thermal Solutions

- In which fields are fluidized bed vertical tube furnaces commonly applied? Explore Key Uses in Materials Science and Energy

- What role does a tube furnace play in Se/NC composite synthesis? Mastering the Melt-Diffusion Method

- What makes a vertical tube furnace easy to operate? Discover Intuitive Automation for Precision Heating

- Why is a sealed vacuum quartz tube required for synthesis of 1T-SnS2 via CVT? Ensure Pure Crystal Growth