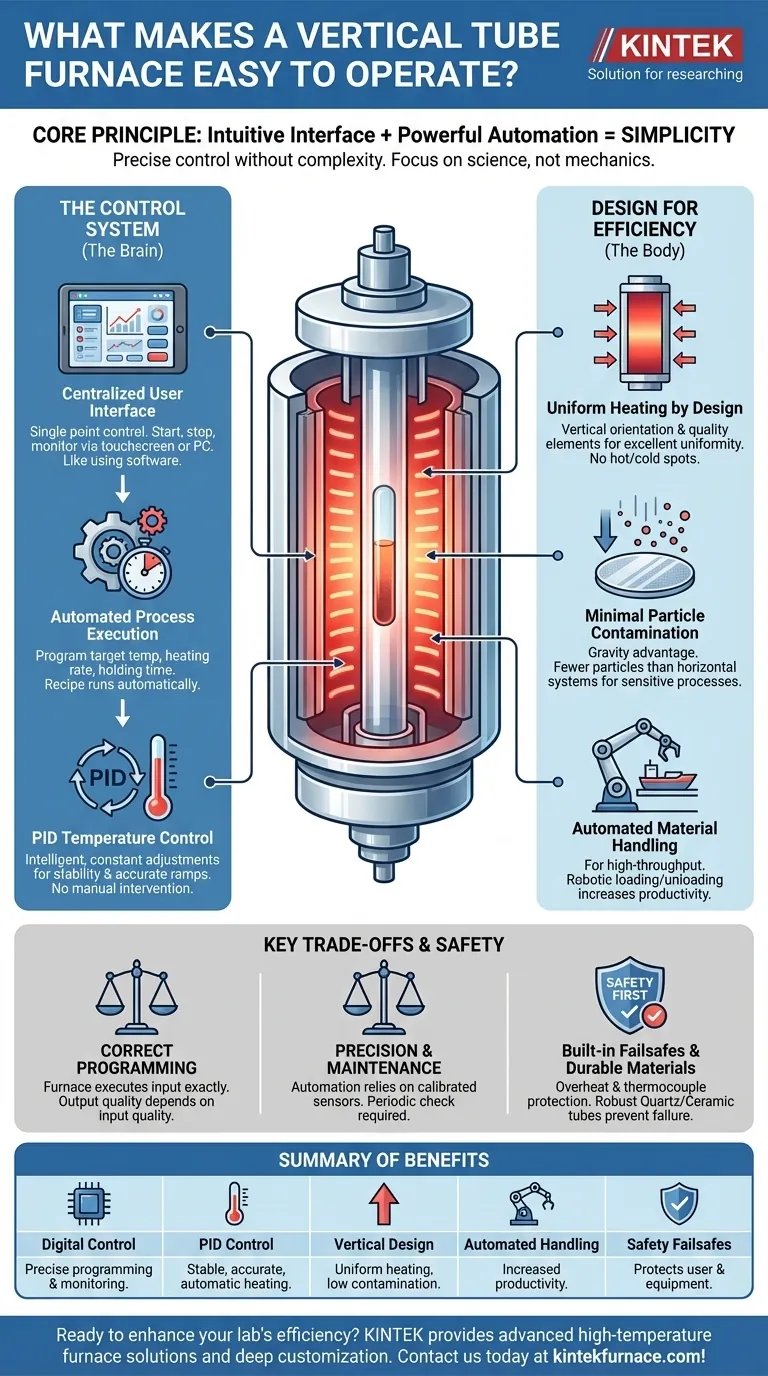

At its core, a vertical tube furnace is easy to operate because its design combines an intuitive user interface with a powerful automated control system. This allows users to precisely define complex heating processes through simple inputs, entrusting the system to manage the intricate details of temperature ramps, stability, and timing.

The operational simplicity of a vertical tube furnace is not about a lack of sophistication. It is the direct result of advanced automation that handles complex thermal variables, freeing the operator to focus on the scientific process and outcomes, not the mechanics of the equipment.

The Foundation of Simplicity: The Control System

The primary driver behind the ease of use is the furnace's digital control system. This system acts as the brain, translating the user's high-level goals into precise, low-level actions.

The Centralized User Interface

Modern vertical tube furnaces feature a concise and clear interface, typically a touchscreen control panel or a connection to a remote PC. This single point of control eliminates the need to manually adjust multiple components.

From here, an operator can start, stop, and monitor the entire process, making operation feel more like using a software application than managing industrial hardware.

Automated Process Execution

The true power lies in automation. Users can program key parameters such as the target temperature, the heating rate (how fast to get there), and the holding time.

Once programmed, the furnace executes the recipe automatically. This removes the potential for human error in timing or adjustment, ensuring process consistency.

PID Temperature Control

Behind the scenes, a PID (Proportional-Integral-Derivative) controller is the workhorse of temperature management. It constantly measures the furnace temperature and intelligently adjusts the heating power.

This ensures the furnace remains incredibly stable at the set temperature and follows programmed heating ramps with high accuracy, all without any operator intervention.

How Design Enhances Operational Efficiency

The physical design of a vertical tube furnace is inherently optimized for specific processes, which further simplifies its day-to-day operation.

Uniform Heating by Design

The vertical orientation, combined with high-quality heating elements and insulation, promotes excellent temperature uniformity throughout the heating zone.

This design reduces the need for complex sample placement or constant monitoring to avoid hot or cold spots, simplifying the setup for achieving homogeneous heat treatment.

Minimal Particle Contamination

For sensitive processes like semiconductor manufacturing, the vertical setup uses gravity to its advantage. This results in minimal particle generation and contamination compared to horizontal systems, improving yield and reducing process complexity.

Automated Material Handling

In production environments, many vertical furnaces can be equipped with automatic wafer and boat transfer systems. This automates the loading and unloading of samples, dramatically increasing productivity and reducing the need for manual handling.

Understanding the Key Trade-offs

While modern furnaces are designed for simplicity, their effective operation relies on a correct understanding of the process and the equipment's capabilities.

Automation Relies on Correct Programming

The furnace will execute the instructions it is given with high fidelity. "Easy to operate" does not mean the furnace can design the experiment for you.

An incorrect heating rate or temperature setpoint will be executed just as precisely as a correct one. The quality of the output is entirely dependent on the quality of the input parameters.

Precision Requires Maintenance

The system's automation and precision depend on properly functioning components. Thermocouples and PID controllers require periodic calibration to ensure their accuracy.

A poorly maintained furnace may appear easy to operate, but it will not deliver the reliable or repeatable results it is designed for.

Safety as a Cornerstone of Operability

An instrument is only easy to use if the operator feels safe. Vertical tube furnaces integrate critical safety features that build confidence and protect both the user and the equipment.

Built-in Failsafes

Features like overheating and thermocouple disconnection protection are standard. If the system detects a temperature spike beyond the setpoint or a sensor failure, it automatically cuts power to the heating elements.

This automated protection provides a crucial safety net, allowing the operator to run processes with confidence, even unattended.

High-Quality, Durable Materials

Furnace tubes are made from robust materials like quartz, ceramic, or high-performance metal alloys. These are selected for high-temperature resistance and chemical inertness.

Using the correct tube material for the process prevents catastrophic failure and ensures safe containment of the sample and any process atmosphere.

Making the Right Choice for Your Goal

The "ease of use" you require depends entirely on your application. Use these points to guide your evaluation.

- If your primary focus is research and development: Prioritize a flexible control system that allows you to easily program complex, multi-stage temperature recipes.

- If your primary focus is high-throughput production: Focus on the level of automation, including robotic material handling and remote system monitoring for maximum efficiency.

- If your primary focus is safety and process integrity: Scrutinize the built-in safety interlocks, over-temperature protection, and the quality of the furnace tube materials.

An easy-to-operate furnace empowers you to achieve precise, repeatable results by managing complexity on your behalf.

Summary Table:

| Feature | Benefit |

|---|---|

| Digital Control System | Enables precise programming and monitoring via touchscreen or PC interface |

| PID Temperature Control | Ensures stable, accurate heating without manual adjustments |

| Vertical Design | Promotes uniform heating and reduces contamination risks |

| Automated Material Handling | Increases productivity with robotic loading/unloading systems |

| Built-in Safety Failsafes | Protects against overheating and sensor failures for safe operation |

Ready to enhance your lab's efficiency with an easy-to-operate furnace? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our tailored solutions can deliver precise, repeatable results for your specific needs!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing