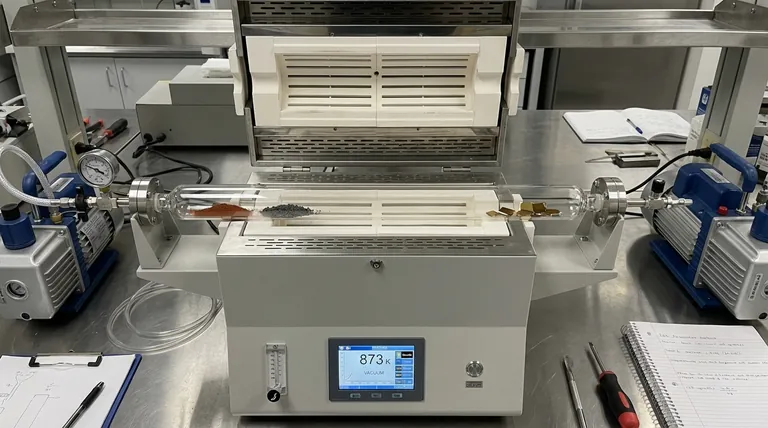

A sealed vacuum quartz tube is strictly required to create a chemically isolated, high-temperature environment necessary for crystal growth. For the synthesis of 1T-SnS2, this vessel specifically prevents the oxidation of Tin (Sn) and Sulfur (S) while confining the precise vapor pressures needed for transport at temperatures reaching 873 K.

Core Takeaway

The sealed vacuum quartz tube serves a dual purpose: it acts as a robust thermal shield against extreme heat and as a chemical barrier against atmospheric contamination. By removing air interference, the tube allows the raw materials to reach a specific vapor pressure equilibrium, which is the fundamental driver for growing pure, non-oxidized 1T-SnS2 single crystals.

The Critical Role of the Vacuum Environment

Prevention of Oxidation

The primary function of the vacuum is to remove air from the reaction vessel. Tin (Sn) and Sulfur (S) are highly reactive raw materials that degrades rapidly in the presence of oxygen.

By sealing these materials under vacuum, you ensure that the 1T-SnS2 crystals remain free from oxidation throughout the growth process.

Eliminating Side Reactions

Beyond simple oxidation, atmospheric moisture can induce undesirable side reactions. These impurities interfere with the chemical equilibrium necessary for high-quality crystallization.

A sealed environment ensures that the interaction is strictly between the raw materials and the transport agent, preventing the formation of byproducts that could ruin the crystal lattice.

Why Quartz is the Material of Choice

Withstanding High Synthesis Temperatures

The synthesis of 1T-SnS2 requires sustained heating at approximately 873 K. Standard glass cannot survive these temperatures without softening or melting.

Quartz possesses the thermal stability required to maintain its structural integrity during this intense heating phase, ensuring the reaction vessel does not collapse.

Chemical Inertness

Quartz provides a chemically neutral environment. It does not react with the vaporized Tin, Sulfur, or the transport agent being used.

This inertness is vital for maintaining stoichiometric precision, ensuring the final crystal is purely 1T-SnS2 without contamination from the container itself.

Facilitating the Transport Mechanism

Controlling Vapor Pressure

Chemical Vapor Transport (CVT) relies on generating specific vapor pressures to move material from a source zone to a growth zone.

The sealed tube creates a closed physical-chemical system. This confinement allows the internal pressure to build to the exact levels required to dissolve and transport the solids via the vapor phase.

Enabling a Stable Equilibrium

For the transport reaction to proceed efficiently, the system must reach a state of chemical equilibrium.

The vacuum-sealed tube allows the transport agent (such as iodine) and the precursors to interact continuously without the loss of volatile species to the outside environment.

Understanding the Trade-offs

Pressure Hazards

While the sealed tube is necessary for pressure buildup, it introduces a risk of over-pressurization. If the temperature exceeds the limits of the quartz or if the reactant load is too high, the tube can explode.

Sealing Complexity

Achieving a high vacuum (often up to $10^{-5}$ mbar) requires precise technical skill. An imperfect seal or a micro-crack in the quartz will lead to immediate oxidation and a failed synthesis batch.

Making the Right Choice for Your Goal

To ensure the successful synthesis of 1T-SnS2, you must match your hardware preparation to your specific purity goals.

- If your primary focus is Phase Purity: Ensure the quartz tube is sealed at a high vacuum (approx. $10^{-5}$ mbar) to completely eliminate moisture and oxygen interference.

- If your primary focus is Safety and Stability: Verify that the wall thickness of the quartz tube is rated to withstand the internal pressures generated at 873 K to prevent rupture.

The sealed quartz tube is not just a container; it is the active isolation chamber that makes the physics of Chemical Vapor Transport possible.

Summary Table:

| Feature | Requirement for 1T-SnS2 Synthesis | Benefit for CVT Process |

|---|---|---|

| Vacuum Level | High vacuum (~10⁻⁵ mbar) | Prevents oxidation of Sn and S; eliminates side reactions. |

| Material | High-purity Quartz | Withstands 873 K temperatures and maintains chemical inertness. |

| Environment | Hermetically Sealed Tube | Confines vapor pressure to facilitate material transport. |

| Stability | Structural Integrity | Prevents contamination and ensures stoichiometric precision. |

Elevate Your Material Synthesis with KINTEK Precision

Achieving the perfect 1T-SnS2 single crystal requires more than just a vacuum—it requires equipment designed for extreme precision. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for the rigorous demands of Chemical Vapor Transport (CVT).

Whether you need customizable high-temp furnaces or reliable thermal processing solutions, our systems provide the stable environment necessary for your most sensitive research. Contact KINTEK today to discover how our advanced laboratory furnaces can optimize your synthesis workflows and ensure unmatched phase purity.

Visual Guide

References

- S. De Stefano, Antonio Di Bartolomeo. Neuromorphic Photoresponse in Ultrathin SnS<sub>2</sub>-Based Field Effect Transistor. DOI: 10.1021/acsami.5c11651

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How does a single-zone tube furnace facilitate the growth of Cu2Se thin films via CVD? Precision Thermal Control Guide

- What role does a vacuum tube furnace play as a reactor during the coal gasification reaction stage?

- What role does a high-temperature tube furnace play in Mo2C synthesis? Master Carbonization Precision

- What role does a vacuum tube furnace play in the 600°C high-temperature annealing of Pd/TaTiNbZr/Ta multilayer membranes?

- How is a Tube Furnace utilized in the color modification process of beryl? Master Deep Blue Aquamarine Transformation

- What critical environmental conditions does a tube furnace provide for volcanic rock thermal cycling? Expert Guide

- What are the methods for treating exhaust gas using a tube furnace? Safely Neutralize Hazards in Your Lab

- What is the primary purpose of using a tube furnace during the desizing phase? Optimize Carbon Fiber Surface Purity