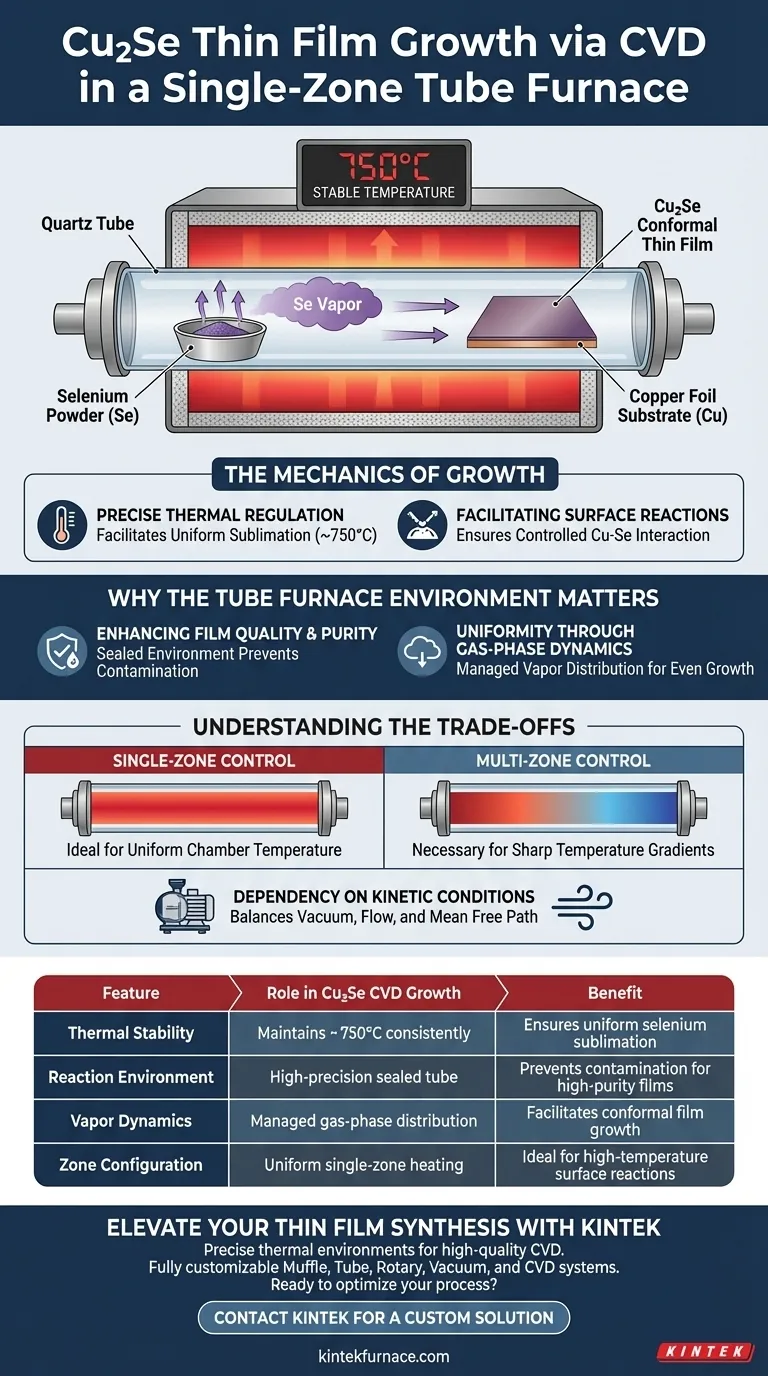

The single-zone tube furnace functions as the primary thermal reactor for synthesizing copper selenide (Cu2Se) thin films via Chemical Vapor Deposition (CVD). It creates a high-precision thermal environment, often maintained at stable temperatures around 750°C, which is critical for driving the reaction between selenium and copper. This specific thermal profile allows for the uniform sublimation of selenium powder and ensures controlled surface chemical reactions on the copper foil substrate.

By maintaining a consistent temperature profile, the single-zone furnace facilitates the thermodynamic conditions required for high-quality, conformal film growth, ensuring that the selenium vapor reacts efficiently with the copper substrate.

The Mechanics of Cu2Se Growth

Precise Thermal Regulation

The core function of the single-zone tube furnace in this process is temperature stability. For Cu2Se growth, the system is typically heated to approximately 750°C.

This high-temperature environment is not arbitrary; it provides the specific energy required to sublimate solid selenium powder into a vapor state. Without this controlled heating, the precursor material would not volatilize at the rate necessary for consistent deposition.

Facilitating Surface Reactions

Once the selenium is vaporized, the furnace environment dictates how it interacts with the substrate. In this specific CVD process, the substrate is a copper foil.

The heated chamber ensures that the chemical reaction between the selenium vapor and the copper foil surface occurs uniformly. This controlled interaction results in the growth of conformal Cu2Se films that adhere well to the substrate topography.

Why the Tube Furnace Environment Matters

Enhancing Film Quality and Purity

Tube furnaces are engineered to produce uniform, dense, and high-purity materials. Because the CVD process occurs in a controlled gas/vapor phase environment, reactants can mix and interact without introducing external contaminants.

By accurately controlling the reaction conditions within the tube, the system avoids impurities often found in liquid-phase or open-air reactions. This leads to "ideal" film quality suitable for advanced applications.

Uniformity Through Gas-Phase Dynamics

The enclosed nature of the tube furnace allows for the management of vapor distribution. As the selenium sublimates, the vapor fills the reaction zone, surrounding the copper substrate.

This ensures that the film grows evenly across the surface of the foil, rather than accumulating effectively in one area and poorly in another.

Understanding the Trade-offs

Single-Zone vs. Multi-Zone Control

While a single-zone furnace is highly effective for reactions requiring a uniform temperature across the entire chamber (like the 750°C required here), it has limitations compared to multi-zone systems.

A single-zone furnace cannot easily create a sharp temperature gradient. If a process required the source material to be at a high temperature and the substrate at a significantly lower temperature simultaneously, a multi-zone configuration would be necessary.

Dependency on Kinetic Conditions

The success of the growth is not solely dependent on heat; it relies on the balance of kinetics within the tube.

Factors such as vacuum levels and the mean free path of reaction gases (how far molecules travel before colliding) play a role. While the furnace provides the heat, the operator must still optimize these pressure and flow parameters to ensure the vapor actually reaches the substrate efficiently.

Making the Right Choice for Your Goal

To maximize the quality of your thin films, consider how the equipment aligns with your specific synthesis requirements.

- If your primary focus is Cu2Se synthesis on copper foil: Rely on the single-zone furnace to maintain a uniform 750°C environment, ensuring consistent sublimation and surface reaction.

- If your primary focus is complex transport deposition: Consider that single-zone systems are best for uniform heating; processes requiring distinct source and deposition temperatures may require multi-zone equipment.

- If your primary focus is high-purity electronic applications: Leverage the sealed tube environment to strictly control contaminants, as this is the primary advantage of CVD over other deposition methods.

The single-zone tube furnace remains the standard for this application because it delivers the exact thermal consistency required to transform solid precursors into high-quality, conformal thin films.

Summary Table:

| Feature | Role in Cu2Se CVD Growth | Benefit |

|---|---|---|

| Thermal Stability | Maintains ~750°C consistently | Ensures uniform selenium sublimation |

| Reaction Environment | High-precision sealed tube | Prevents contamination for high-purity films |

| Vapor Dynamics | Managed gas-phase distribution | Facilitates conformal film growth on copper foil |

| Zone Configuration | Uniform single-zone heating | Ideal for high-temperature surface reactions |

Elevate Your Thin Film Synthesis with KINTEK

Precise thermal environments are the foundation of high-quality CVD material growth. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique research and production needs.

Whether you are synthesizing Cu2Se thin films or developing next-generation electronic materials, our high-temperature lab furnaces provide the uniformity and purity your work demands.

Ready to optimize your deposition process? Contact KINTEK today for a custom solution!

Visual Guide

References

- Rajesh Rajasekharan, Manikoth M. Shaijumon. Bifunctional Current Collectors for Lean‐Lithium Metal Batteries. DOI: 10.1002/adfm.202502473

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What is the function of a tube furnace in palladium nanonetwork pretreatment? Unlock High Ductility and Zero Oxidation

- What is the primary function of a high-temperature tube furnace in Se@void@BLNC preparation? Master Dual Synthesis

- Why is a tube furnace with multiple zones required for MoSe2 selenization? Achieve Precision Gradient Control

- How does the positioning of a quartz tube in a vertical tube furnace contribute to the stability of the synthesis reaction?

- What are the key capabilities of the 3-Zone tube furnace? Achieve Precise Thermal Control for Your Lab

- What is the function of a tube furnace for bond-coated substrates? Ensure TBC Durability with Controlled Pre-Oxidation

- What is the function of a dual-zone tube furnace in LPCVD? Master Precise MnSe Nanosheet Synthesis

- What factors should be considered when choosing between vertical and horizontal tube furnaces? Optimize Your Lab's Performance