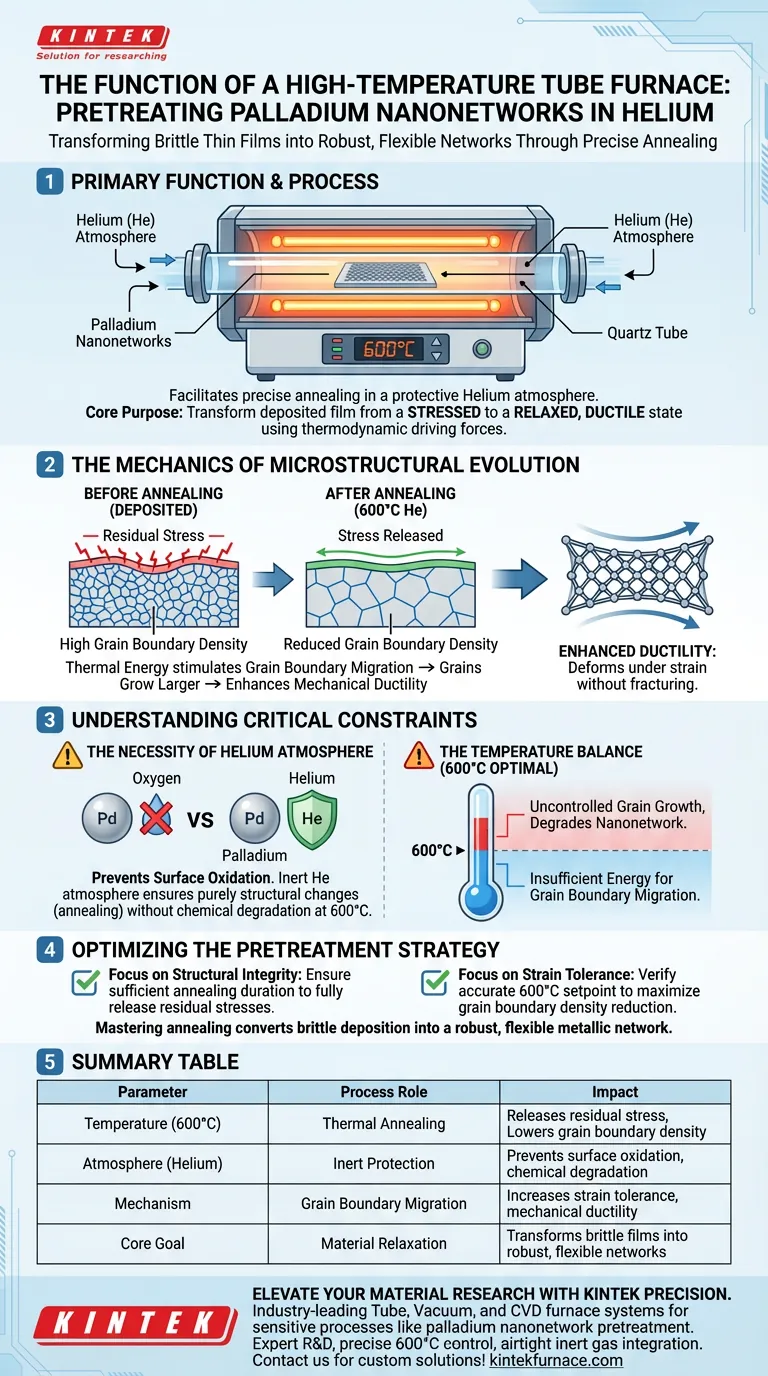

The primary function of a high-temperature tube furnace in this context is to facilitate a precise annealing process for deposited palladium thin films. By maintaining a steady temperature of 600°C within a protective helium (He) atmosphere, the furnace provides the thermal environment necessary to fundamentally alter the material's physical state without risking oxidation.

The core purpose of this treatment is to transform the deposited film from a stressed state to a relaxed, ductile state. It utilizes thermodynamic driving forces to lower grain boundary density, thereby significantly increasing the material's strain tolerance.

The Mechanics of Microstructural Evolution

To understand why this equipment is essential, one must look beyond simple heating and examine the microstructural changes occurring within the palladium nanonetworks.

Releasing Residual Stress

During the initial deposition phase, metallic films invariably accumulate internal tension.

If left untreated, this residual stress can lead to delamination or cracking.

The 600°C environment allows the atomic structure to relax, effectively neutralizing these internal forces before the material is put into service.

Reducing Grain Boundary Density

The thermal energy provided by the tube furnace acts as a powerful thermodynamic driving force.

This energy stimulates the movement of grain boundaries—the interfaces between individual crystals in the metal.

As the material anneals, these boundaries migrate and the grains grow larger, leading to a net reduction in the overall density of grain boundaries.

Enhancing Mechanical Ductility

The reduction of grain boundaries is directly linked to the mechanical performance of the nanonetwork.

Fewer boundaries mean there are fewer obstacles to dislocation movement within the crystal lattice.

This structural change significantly enhances ductility, allowing the palladium nanonetworks to stretch and deform under strain without fracturing.

Understanding the Critical Constraints

While the benefits are clear, the process relies on strict adherence to environmental parameters. Deviating from these conditions creates immediate trade-offs.

The Necessity of the Helium Atmosphere

The use of a helium environment is not optional; it is a critical protective measure.

At 600°C, palladium is highly susceptible to reaction with oxygen.

The inert helium atmosphere prevents surface oxidation, ensuring that the changes to the material are purely structural (annealing) rather than chemical (corrosion).

The Temperature Balance

The specific target of 600°C represents a calculated optimal point.

Temperatures significantly lower than this may fail to provide sufficient energy to activate grain boundary migration.

Conversely, excessive temperatures could lead to uncontrolled grain growth, potentially degrading the fine resolution of the nanonetwork structure.

Optimizing the Pretreatment Strategy

To ensure the integrity of palladium nanonetworks, you must verify that your thermal processing aligns with your specific mechanical goals.

- If your primary focus is structural integrity: Ensure the annealing duration is sufficient to fully release residual stresses accumulated during deposition.

- If your primary focus is strain tolerance: Verify that the furnace accurately maintains the 600°C setpoint to maximize the reduction of grain boundary density.

Mastering this annealing step is the definitive factor in converting a brittle deposition into a robust, flexible metallic network.

Summary Table:

| Parameter | Process Role | Impact on Palladium Nanonetwork |

|---|---|---|

| Temperature (600°C) | Thermal Annealing | Releases residual stress and lowers grain boundary density |

| Atmosphere (Helium) | Inert Protection | Prevents surface oxidation and chemical degradation |

| Mechanism | Grain Boundary Migration | Increases strain tolerance and mechanical ductility |

| Core Goal | Material Relaxation | Transforms brittle films into robust, flexible networks |

Elevate Your Material Research with KINTEK Precision

Are you looking to optimize the ductility and structural integrity of your advanced thin films? KINTEK provides industry-leading Tube, Vacuum, and CVD furnace systems designed specifically for sensitive processes like palladium nanonetwork pretreatment.

Backed by expert R&D and manufacturing, our furnaces offer precise 600°C control and airtight inert gas integration to ensure your materials transition from brittle to robust without the risk of oxidation. Whether you need standard lab equipment or a fully customized high-temperature solution, KINTEK is your partner in material science excellence.

Ready to refine your thermal processing? Contact us today for a custom solution!

Visual Guide

References

- Kaihao Zhang, Sameh Tawfick. Ultrathin damage-tolerant flexible metal interconnects reinforced by in-situ graphene synthesis. DOI: 10.1038/s41528-024-00300-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does a fast Joule-heating device differ from a tubular furnace? Kinetic vs. Thermodynamic Control

- How does the diversification of vacuum tube furnaces impact the market? Unlock Specialized Solutions for Advanced Materials

- What is the working principle of a fluidized bed vertical tube furnace? Achieve Superior Heat Treatment Efficiency

- What are the technical advantages of using a PID programmable controller in tube furnace control modules?

- What are the main benefits of using a tube furnace? Achieve Precise Temperature and Atmosphere Control

- Why is a laboratory tube furnace necessary for BiVO4/RGO synthesis? Achieve Precise Nano-Structure Control

- What are the types of Tube Furnaces based on tube shape? Choose Between Solid and Split for Your Lab

- What is the primary purpose of using an atmosphere-protected tube furnace? Optimize N/S Co-Doped Carbon Synthesis