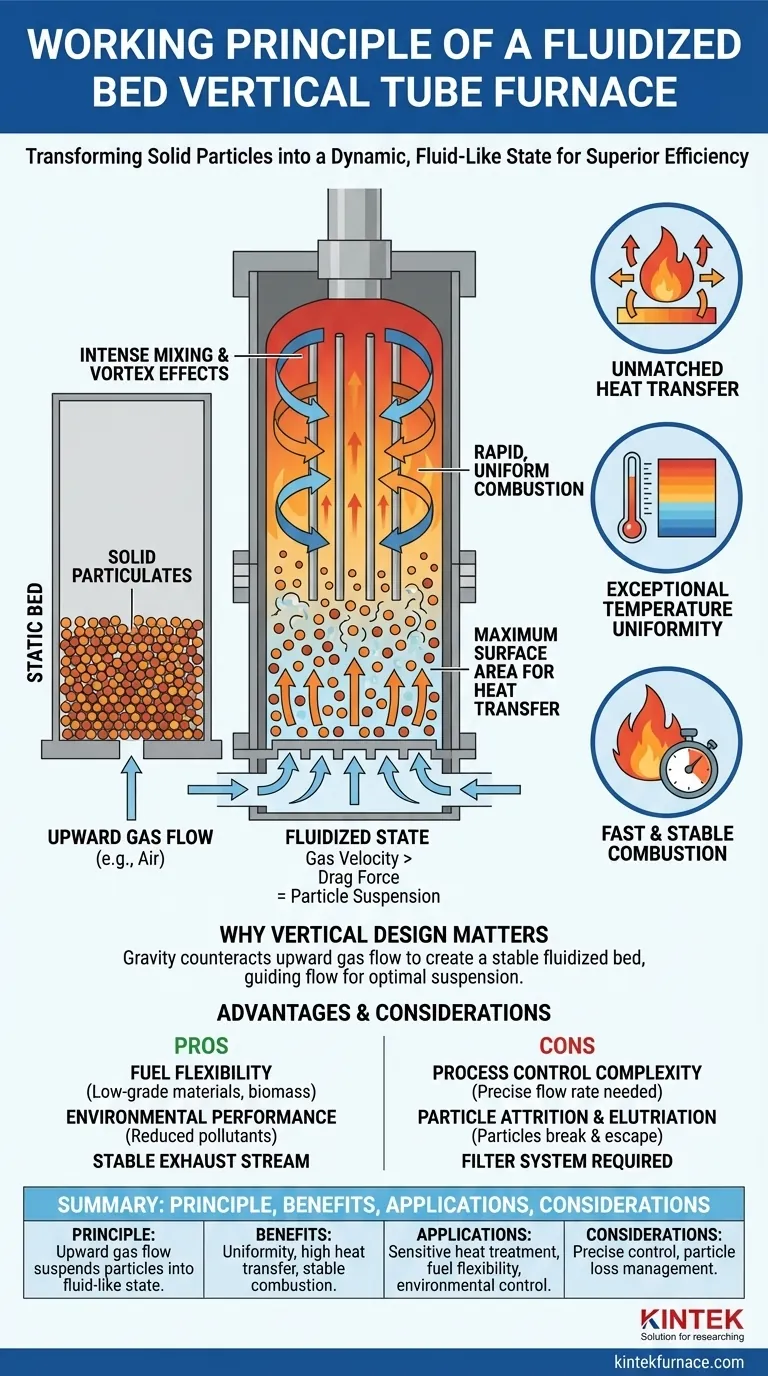

At its core, the working principle of a fluidized bed vertical tube furnace is the controlled use of upward-flowing gas to suspend solid fuel particles, transforming the static bed of material into a dynamic, fluid-like state. This "fluidization" creates exceptionally intimate contact between the gas and the solid particles, leading to rapid, uniform, and highly efficient combustion or heat treatment.

The key takeaway is not just that particles are suspended, but that this suspension forces the entire system—gas and solids—to behave like a boiling liquid. This fluid-like behavior is the source of its primary advantages: unparalleled temperature uniformity and dramatically enhanced heat transfer efficiency.

The Core Mechanism: From Solid Bed to Fluidized State

To understand this furnace, you must first understand the principle of fluidization. It is a physical phenomenon, not a chemical one, that fundamentally alters how the materials interact.

The Role of Upward Gas Flow

The process begins by forcing a gas, such as air for combustion, upward through a distributor plate at the bottom of the furnace chamber. This gas then flows through a bed of solid particulate material (like coal, biomass, or sand) that rests on the plate.

Achieving Particle Suspension

As the velocity of the gas increases, it exerts an upward drag force on the solid particles. When this force becomes equal to the downward gravitational force, the particles become suspended in the gas stream. The entire bed expands and begins to move, no longer behaving as a packed solid.

The "Fluid-Like" Behavior

At the correct gas velocity, the suspended particles and gas mixture exhibit the properties of a fluid. It will bubble, mix vigorously, and create intense "vortex effects." This constant motion ensures every particle is continuously exposed to the gas stream, a key differentiator from static furnaces where gas may only pass over the surface of the material.

Why This Design Delivers Superior Performance

The vertical structure and fluidized bed technology are not separate features; they work in concert to create a highly effective heating environment.

Unmatched Heat Transfer Efficiency

The "fluid-like" state creates a massive surface area for contact between the gas and the solid particles. This intimate contact allows for extremely rapid and efficient heat transfer, ensuring that the energy from combustion is absorbed quickly by the material or the furnace's internal tubes.

Exceptional Temperature Uniformity

In a conventional furnace, "hot spots" are a common problem. The intense mixing action within a fluidized bed constantly redistributes the particles, eliminating temperature gradients. The entire bed operates at a near-uniform temperature, which is critical for sensitive processes and for preventing material damage.

Fast and Stable Combustion

Because particles are heated so quickly and uniformly, they reach their combustion temperature almost instantly. This leads to a very fast reaction speed and a highly stable, controlled combustion process once the bed is fully fluidized.

The Significance of the Vertical Structure

The vertical orientation of the furnace and its internal tube bundles is essential. It allows gravity to work against the upward gas flow, which is the fundamental force balance required to create a stable fluidized bed. This design naturally guides the flow and promotes the desired suspension.

Understanding the Operational Advantages and Trade-offs

While powerful, this technology is not universally superior. Its benefits come with specific operational considerations that must be understood.

Advantage: Fuel Flexibility

The high combustion efficiency and stable temperature make fluidized bed furnaces adaptable to a wide variety of solid fuels. This includes low-grade materials like high-ash coal or biomass, which may not burn effectively in other furnace types.

Advantage: Environmental Performance

The stable and controlled combustion at a uniform temperature can reduce the formation of pollutants like NOx. Furthermore, the predictable nature of the exhaust gas stream makes it easier to design effective purification and filtering systems to meet emission standards.

Consideration: Process Control Complexity

The system's performance is critically dependent on maintaining the precise gas flow rate and pressure required for fluidization. This requires a more sophisticated control system than a simple static furnace, demanding careful monitoring and adjustment.

Consideration: Particle Attrition and Elutriation

The constant, vigorous motion can cause particles to wear down or break apart (attrition). Very fine particles can then be carried out of the bed by the gas flow (elutriation), requiring a cyclone or filter system to capture them.

Making the Right Choice for Your Application

Selecting the right furnace technology depends entirely on your primary processing goals. A fluidized bed furnace excels in specific scenarios but may be over-engineered for others.

- If your primary focus is maximum thermal efficiency and uniformity: This design is ideal, as the intense mixing provides superior gas-solid contact and eliminates hot spots.

- If you are processing materials sensitive to temperature variations: The exceptional temperature uniformity of a fluidized bed minimizes the risk of overheating or damaging your material.

- If you require flexibility in using various solid or low-grade fuels: The high combustion efficiency allows for the effective use of a wide range of solid particulate fuels.

- If your priority is simplicity and minimal operational oversight: A conventional static furnace may be a better choice due to its simpler control requirements.

By understanding the fundamental principle of fluidization, you can make an informed decision based on your specific technical and operational needs.

Summary Table:

| Aspect | Description |

|---|---|

| Principle | Upward gas flow suspends solid particles, creating a fluid-like state for enhanced contact. |

| Key Benefits | Unmatched temperature uniformity, high heat transfer efficiency, and stable combustion. |

| Applications | Ideal for sensitive heat treatment, fuel flexibility with low-grade materials, and environmental control. |

| Considerations | Requires precise gas flow control; may involve particle attrition and elutriation. |

Unlock the Power of Fluidized Bed Technology for Your Lab! Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need superior heat transfer, temperature uniformity, or fuel flexibility, we can tailor a solution to enhance your efficiency and results. Contact us today to discuss how our furnaces can transform your processes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing