In short, a tube furnace excels at providing highly uniform temperature and precise atmospheric control in a compact and efficient design. Its core benefits stem from its enclosed, cylindrical heating chamber, which makes it exceptionally versatile for a wide range of scientific and industrial processes that require controlled environments, from material synthesis to thermal treatment.

The true power of a tube furnace is not just its ability to get hot, but its ability to create a perfectly controlled micro-environment. This unique combination of uniform heating and atmospheric isolation is what makes it an indispensable tool for advanced material processing.

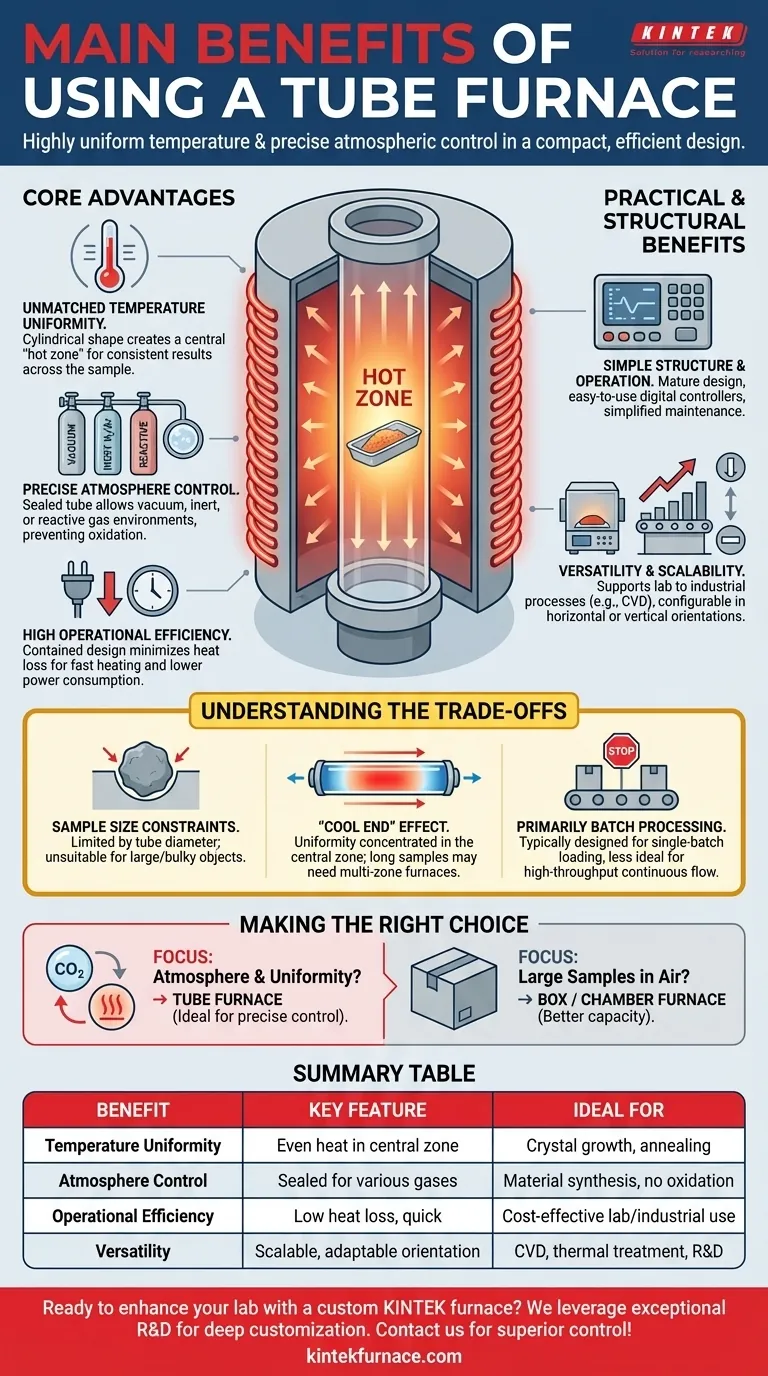

The Core Advantages of a Tube Furnace Design

A tube furnace's benefits are a direct result of its fundamental structure: a heating element (or elements) surrounding a ceramic or metallic tube that contains the sample. This simple design principle unlocks several powerful capabilities.

Unmatched Temperature Uniformity

The cylindrical shape naturally promotes even heat distribution around the circumference of the tube. While the ends of the furnace are typically cooler, this creates a central "hot zone" with exceptional temperature uniformity.

This uniformity is critical for processes where every part of the sample must experience the exact same temperature to ensure consistent results, such as in crystal growth or annealing.

Precise Atmosphere Control

This is arguably the most significant advantage. The enclosed tube can be sealed, allowing you to completely control the gaseous environment around your sample.

You can create a vacuum to remove reactive gases, introduce an inert gas (like Argon or Nitrogen) to prevent oxidation, or use a reactive gas to actively participate in a chemical process. This level of control is difficult or impossible to achieve in other furnace types, like a standard box furnace.

High Operational Efficiency

The contained design minimizes heat loss to the surrounding environment. This results in higher thermal efficiency and lower power consumption compared to less-contained furnace designs.

Because the heat is focused on a relatively small volume, the furnace can often reach high target temperatures quickly and maintain them with precision.

Practical and Structural Benefits

Beyond its core thermal and atmospheric performance, the tube furnace offers practical advantages that make it a go-to choice in many laboratories and production facilities.

Simple Structure and Operation

Tube furnaces generally have a mature, straightforward design. They are easy to operate, with precise digital controllers managing temperature profiles, and are structurally simple, which reduces cost and simplifies maintenance.

Versatility and Scalability

Their application is incredibly broad, supporting everything from basic laboratory heat treatment to advanced material synthesis and industrial processes like chemical vapor deposition (CVD).

Furthermore, the design is scalable. Multiple furnaces can be combined to create large-scale or continuous production lines, and they can be configured in both horizontal and vertical orientations to suit specific process needs, such as minimizing particle contamination in vertical setups.

Understanding the Trade-offs

No tool is perfect for every job. To make an informed decision, it is critical to understand the inherent limitations of a tube furnace.

Sample Size and Geometry Constraints

The most obvious limitation is the tube's diameter. You are restricted to processing samples that can physically fit inside the tube. This makes them unsuitable for large, bulky, or irregularly shaped objects, where a box or chamber furnace would be more appropriate.

The "Cool End" Effect

The excellent temperature uniformity is concentrated in the central zone. If you need to heat a very long sample uniformly along its entire length, you may need a multi-zone tube furnace, which uses multiple independent heating elements and controllers to extend the uniform hot zone.

Primarily for Batch Processing

While some industrial designs are built for continuous flow, the majority of laboratory tube furnaces are designed for batch processing. Samples are loaded, processed, and then unloaded one batch at a time, which may not be ideal for high-throughput applications.

Making the Right Choice for Your Application

Selecting the right furnace depends entirely on the specific requirements of your process.

- If your primary focus is material processing under a specific atmosphere: The tube furnace is the definitive choice due to its superior sealing and atmosphere control capabilities.

- If your primary focus is maximum temperature uniformity for a small sample: The central hot zone of a tube furnace provides one of the most uniform heating environments available.

- If your primary focus is processing large, bulky, or numerous samples in air: A box or chamber furnace will likely offer the capacity and flexibility you need.

Ultimately, a tube furnace is the ideal solution for any process where precise control over both heat and atmosphere is the paramount concern.

Summary Table:

| Benefit | Key Feature | Ideal For |

|---|---|---|

| Temperature Uniformity | Even heat distribution in central hot zone | Crystal growth, annealing |

| Atmosphere Control | Sealed tube for vacuum, inert, or reactive gases | Material synthesis, oxidation prevention |

| Operational Efficiency | Minimal heat loss, quick heating, lower power | Cost-effective lab and industrial processes |

| Versatility | Scalable design, horizontal/vertical setups | CVD, thermal treatment, continuous production |

Ready to enhance your lab's capabilities with a custom tube furnace solution? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces, including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for superior temperature and atmosphere control. Contact us today to discuss how we can optimize your material processing!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing