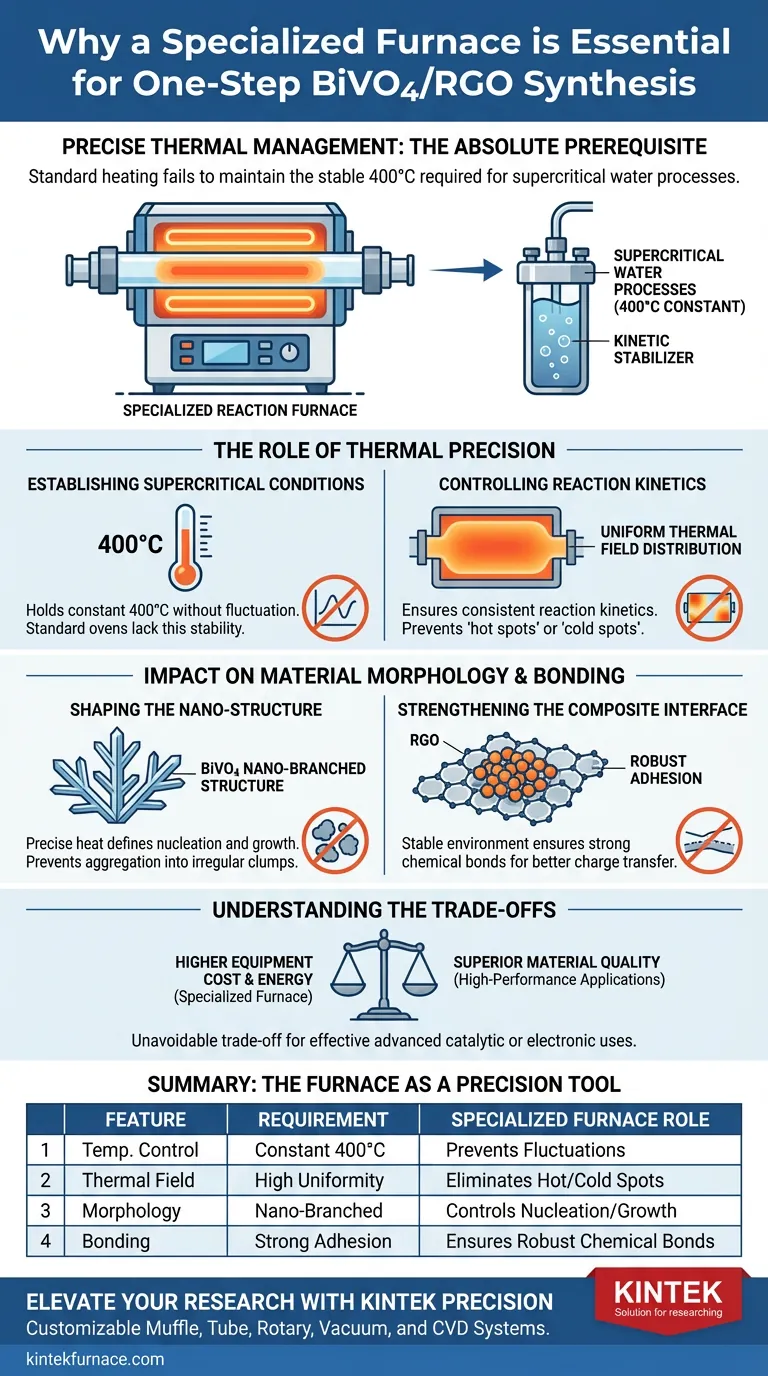

Precise thermal management is the absolute prerequisite for this synthesis. A laboratory tube furnace or specialized reaction furnace is necessary because standard heating methods cannot generate the stable, uniform thermal field required to maintain a constant 400°C environment. This specific temperature control is non-negotiable for facilitating the supercritical water processes that drive the one-step synthesis of BiVO4/RGO composites.

The furnace acts as a kinetic stabilizer, ensuring the uniform thermal distribution necessary to grow specific nano-structures and forge strong chemical bonds between components.

The Role of Thermal Precision

Establishing Supercritical Conditions

The one-step synthesis relies heavily on supercritical water processes. To achieve this state effectively, the reaction environment must be preheated and strictly maintained at 400°C.

A specialized furnace provides the insulation and control logic to hold this temperature without fluctuation. Standard ovens often lack the thermal stability to maintain this specific supercritical threshold.

Controlling Reaction Kinetics

Temperature fluctuations lead to inconsistent reaction rates. A tube furnace provides an accurate thermal field distribution, ensuring that the entire sample is exposed to identical conditions.

This uniformity guarantees consistent reaction kinetics throughout the synthesis vessel. It prevents localized "hot spots" or "cold spots" that would result in a heterogeneous, low-quality product.

Impact on Material Morphology and Bonding

Shaping the Nano-Structure

The physical form of the Bismuth Vanadate (BiVO4) is defined by how heat is applied. The precise thermal field influences the nucleation and growth of the crystals.

Proper furnace control directly facilitates the formation of a distinct BiVO4 nano-branched structure. Without this control, the material may aggregate into irregular clumps rather than the desired branched architecture.

Strengthening the Composite Interface

The effectiveness of the composite depends on how well the BiVO4 attaches to the Reduced Graphene Oxide (RGO). The furnace determines the tightness of this bond.

A stable thermal environment ensures robust adhesion between the semiconductor (BiVO4) and the conductive support (RGO). A weak bond results in poor charge transfer and reduced material performance.

Understanding the Trade-offs

Equipment Complexity vs. Material Quality

Using a specialized reaction furnace introduces higher equipment costs and energy consumption compared to simple hydrothermal autoclaves or hot plates.

However, the trade-off is unavoidable for high-performance applications. Attempting this synthesis with less precise equipment generally yields composites with weak interfacial bonding and undefined morphology, rendering them ineffective for advanced catalytic or electronic uses.

Making the Right Choice for Your Goal

To achieve a successful one-step synthesis, align your equipment choice with your specific material requirements.

- If your primary focus is Morphology Control: Prioritize a furnace with programmable ramping to ensure the distinct formation of BiVO4 nano-branched structures.

- If your primary focus is Composite Stability: Ensure the furnace is calibrated for uniform thermal distribution to maximize the bond tightness between BiVO4 and RGO.

Ultimately, the furnace is not just a heat source, but a precision tool that defines the structural integrity and functionality of your final composite.

Summary Table:

| Feature | Requirement for BiVO4/RGO Synthesis | Role of Specialized Furnace |

|---|---|---|

| Temperature Control | Constant 400°C for supercritical water | Prevents fluctuations to maintain supercritical state |

| Thermal Field | High uniformity across the vessel | Eliminates hot/cold spots for consistent kinetics |

| Morphology | Formation of nano-branched structures | Controls nucleation and crystal growth patterns |

| Interfacial Bonding | Strong adhesion between BiVO4 and RGO | Ensures robust chemical bonding for charge transfer |

Elevate Your Materials Research with KINTEK Precision

High-performance BiVO4/RGO composites demand the absolute thermal stability that only a specialized furnace can provide. KINTEK delivers the precision your lab needs to master supercritical water processes and complex nano-structure synthesis.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique thermal profiles. Don't compromise on material integrity; leverage our expertise to achieve superior interfacial bonding and morphology control.

Ready to optimize your synthesis workflow? Contact KINTEK today to find your custom furnace solution!

Visual Guide

References

- Dinesh Rangappa, Manjunath Shetty. A rapid supercritical water approach for one-pot synthesis of a branched BiVO<sub>4</sub>/RGO composite as a Li-ion battery anode. DOI: 10.1039/d3ra07731d

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Magnesium Extraction and Purification Condensing Tube Furnace

People Also Ask

- How does a tube heating furnace facilitate the carbon coating process? Boost Layered Oxide Conductivity

- How does a high-temperature tube furnace facilitate the ammonolysis process? Master TiNx Nanoparticle Synthesis

- What role does a high-temperature tube furnace play in Pt/MoS2 synthesis? Master Atomic-Level Defect Engineering

- How does air annealing in a tube furnace enhance the performance of TiO2 nanorods? Boost Crystallinity and Conductivity

- What core process conditions does a vacuum tube furnace provide for FeCoNiCrAl coatings? Expert Annealing Guide

- What is the function of a two-zone tube furnace in Borophene CVD? Achieve Precise Thermal Decoupling for 2D Synthesis

- Why is a high-temperature tube furnace utilized for the calcination of nano-zinc oxide? Master Microstructure Control

- How do laboratory tube furnaces contribute to the sintering of Ba0.95La0.05(Fe1-xYx)O3-δ? Precise Atmosphere Control