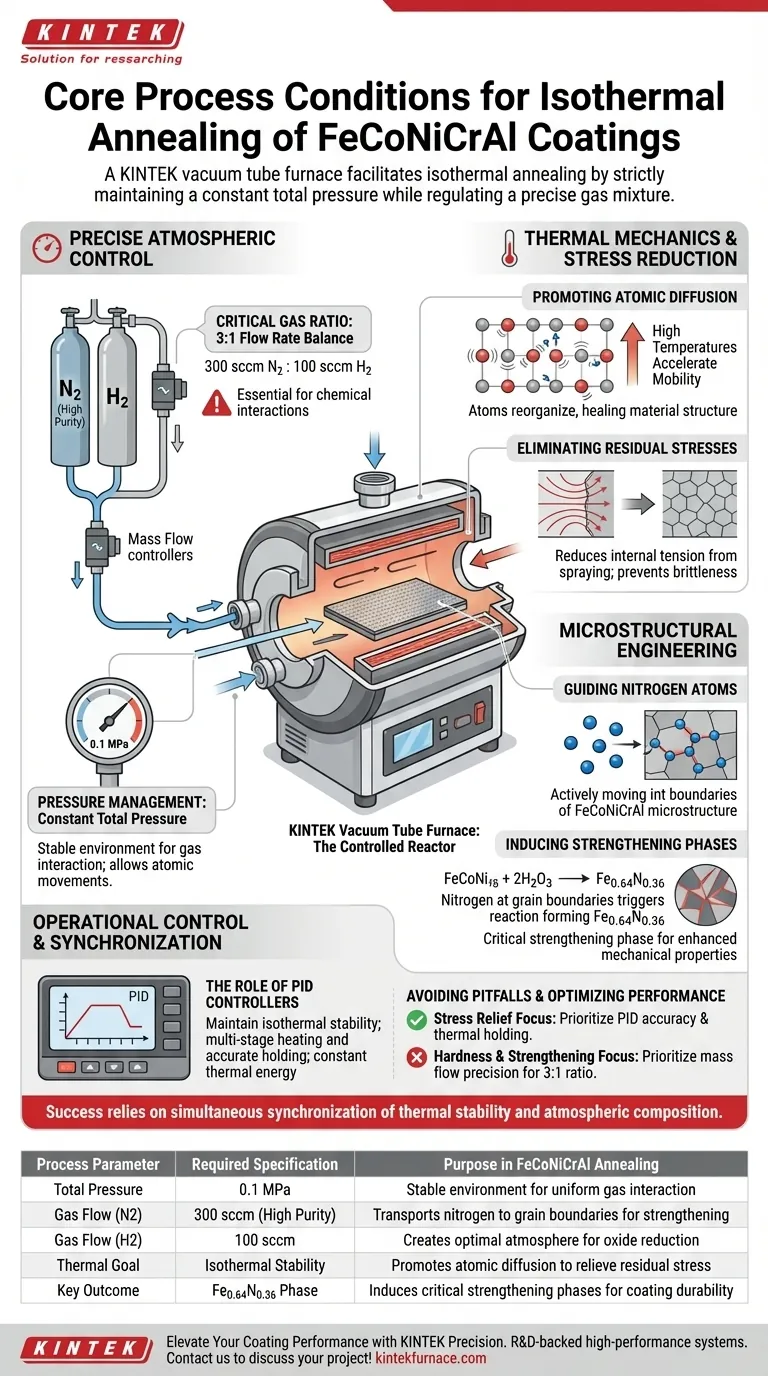

A vacuum tube furnace facilitates isothermal annealing by strictly maintaining a constant total pressure of 0.1 MPa while regulating a precise gas mixture. Specifically, it controls a flow ratio of high-purity nitrogen (300 sccm) to hydrogen (100 sccm) to create the optimal environment for treating FeCoNiCrAl coatings.

The furnace acts as more than a heating element; it functions as a controlled reactor. By combining high-temperature atomic diffusion with a specific Nitrogen-Hydrogen atmosphere, it simultaneously relieves residual spraying stresses and induces the formation of critical strengthening phases like Fe0.64N0.36.

Precise Atmospheric Control

The Critical Gas Ratio

To achieve specific microstructural changes, the furnace must maintain a strict flow rate balance.

The process requires high-purity nitrogen flowing at 300 sccm combined with hydrogen at 100 sccm. This 3:1 ratio is essential for the chemical interactions required during the anneal.

Pressure Management

Stability is key to uniform coating treatment.

The system maintains a constant total pressure of 0.1 MPa throughout the process. This pressure level ensures a stable environment for gas interaction without suppressing the necessary atomic movements.

Thermal Mechanics and Stress Reduction

Promoting Atomic Diffusion

The primary thermal function of the furnace is to utilize high temperatures to accelerate atomic mobility.

This increased mobility allows atoms within the coating to reorganize. This reorganization is fundamental to healing the material structure after deposition.

Eliminating Residual Stresses

Coatings often possess internal tension resulting from the initial spraying process.

By facilitating atomic diffusion, the vacuum tube furnace effectively reduces these residual spraying stresses. This prevents the coating from becoming brittle or failing prematurely.

Microstructural Engineering

Guiding Nitrogen Atoms

The furnace environment is designed to actively transport nitrogen atoms into the material's microstructure.

The controlled atmosphere guides these nitrogen atoms specifically into the grain boundaries of the FeCoNiCrAl coating.

Inducing Strengthening Phases

The presence of nitrogen at the grain boundaries triggers a specific chemical reaction.

This reaction leads to the formation of the Fe0.64N0.36 phase. This is a critical strengthening phase that enhances the mechanical properties of the final coating.

Operational Control and Trade-offs

The Role of PID Controllers

To maintain the "isothermal" aspect of the annealing, precise temperature regulation is required.

Integrated PID controllers are typically used to execute multi-stage heating and accurate holding programs. This ensures the thermal energy remains constant, preventing fluctuations that could alter the diffusion rate.

Potential Pitfalls

It is vital to understand that the gas ratio is not arbitrary.

An imbalance in the Nitrogen-Hydrogen ratio can fail to produce the Fe0.64N0.36 phase or fail to reduce oxides properly. Similarly, deviations in pressure from 0.1 MPa can alter the kinetics of diffusion, leading to incomplete stress relief.

Making the Right Choice for Your Goal

To optimize the performance of FeCoNiCrAl coatings, you must prioritize specific control parameters based on your desired outcome.

- If your primary focus is Stress Relief: Prioritize the accuracy of the PID controller and thermal holding times to maximize atomic diffusion and eliminate residual tension.

- If your primary focus is Hardness and Strengthening: Focus on the precision of the mass flow controllers to ensure the exact 300 sccm N2 to 100 sccm H2 ratio is maintained for phase formation.

Success in this process relies on the simultaneous synchronization of thermal stability and atmospheric composition.

Summary Table:

| Process Parameter | Required Specification | Purpose in FeCoNiCrAl Annealing |

|---|---|---|

| Total Pressure | 0.1 MPa | Stable environment for uniform gas interaction |

| Gas Flow (N2) | 300 sccm (High Purity) | Transports nitrogen to grain boundaries for strengthening |

| Gas Flow (H2) | 100 sccm | Creates optimal atmosphere for oxide reduction |

| Thermal Goal | Isothermal Stability | Promotes atomic diffusion to relieve residual stress |

| Key Outcome | Fe0.64N0.36 Phase | Induces critical strengthening phases for coating durability |

Elevate Your Coating Performance with KINTEK Precision

Achieving the perfect Fe0.64N0.36 strengthening phase requires more than just heat—it demands absolute atmospheric control. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to maintain the precise gas ratios and pressure stability your advanced materials require.

Whether you need a standard setup or a fully customizable system tailored to your unique FeCoNiCrAl research, our team is ready to help you eliminate residual stress and maximize material hardness.

Ready to optimize your thermal processing? Contact KINTEK today to discuss your project!

Visual Guide

References

- Miqi Wang, Shi Fang. Enhancement in Corrosion and Wear Resistance of FeCoNiCrAl High-Entropy Alloy Coating Through Dual Heat Treatment with 3:1 N2/H2 Atmosphere. DOI: 10.3390/coatings15090986

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- How are tube furnaces utilized in nanotechnology? Essential for Precise Nanomaterial Synthesis

- What role do industrial tube furnaces play in the oxidation of NiCrAl alloys? Precise Stability for Reliable Data

- Why is it necessary to use a tube vacuum furnace with an argon atmosphere for sintering aluminum-based materials?

- Why is a high-temperature tube furnace required for LNMO synthesis? Achieve Precise Fd-3m Spinel Structures

- What role does a single-zone tube furnace play in synthesizing ZnPS3? Master the Thermal Profile for Layered Materials

- What is the key function of a tube furnace for AHSS austenitization? Precision Testing for High-Strength Steel

- How does a laboratory high-temperature tube furnace contribute to the conversion of electrospun fibers? Expert Insights

- What critical reaction conditions are provided by a tube furnace for NiS2 synthesis? Achieve Pure Phase Results