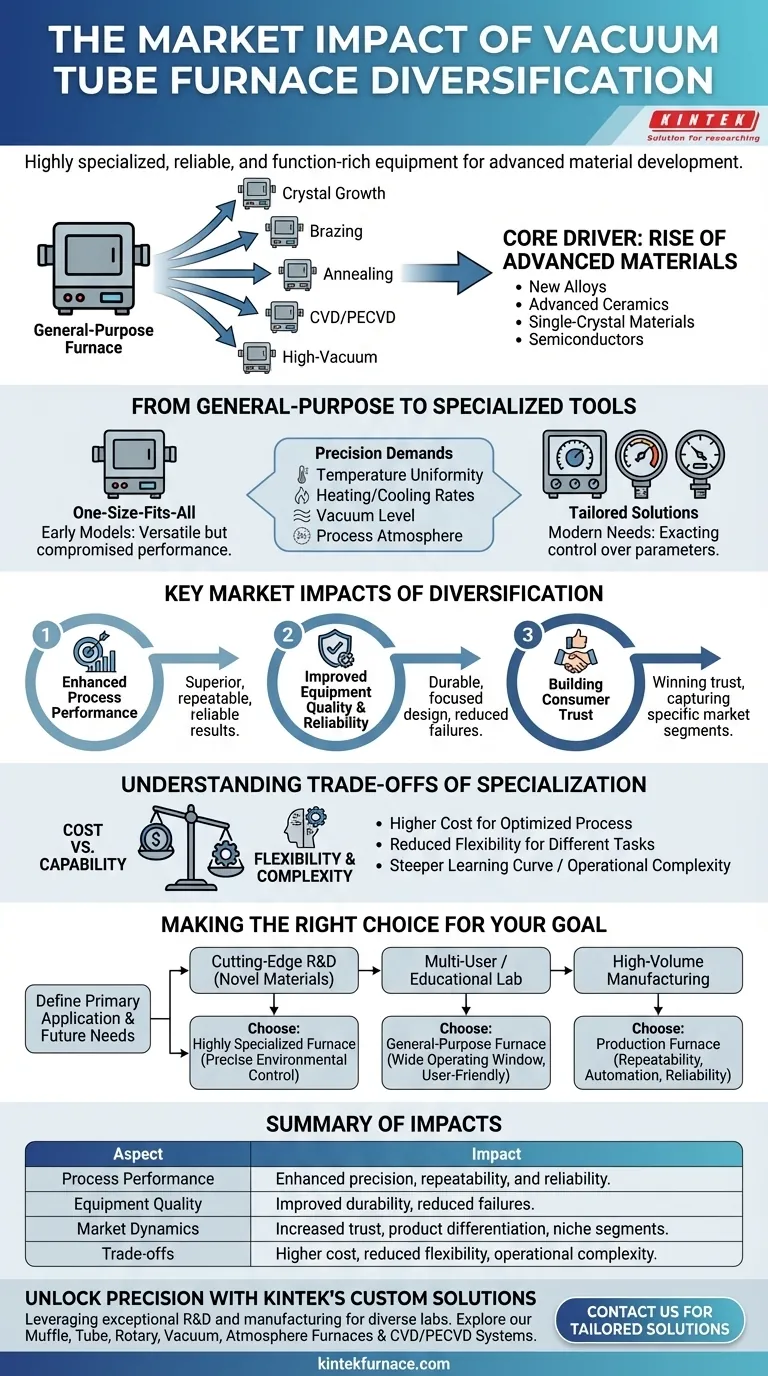

In the field of material processing, the diversification of vacuum tube furnaces directly impacts the market by creating a landscape of highly specialized, reliable, and function-rich equipment. This trend is a direct response to the demands of new material development, allowing manufacturers to offer tailored solutions that build consumer trust and capture specific market segments.

The increasing variety of vacuum tube furnaces is not simply about offering more choice. It signifies a fundamental market shift from general-purpose equipment to specialized tools engineered to solve specific material science challenges, resulting in higher quality and better process performance.

The Core Driver: The Rise of Advanced Materials

The evolution of vacuum tube furnaces is intrinsically linked to the progress of materials science. As researchers and engineers push the boundaries of what's possible, they require tools with greater precision and capability.

From General-Purpose to Specialized Tools

Early furnace models were often designed as "one-size-fits-all" solutions. While versatile, they involved compromises in performance for any single, specific application.

The development of new alloys, advanced ceramics, single-crystal materials, and semiconductors created processing requirements that general-purpose furnaces could not meet effectively.

The Demand for Uncompromising Precision

Creating modern materials requires exacting control over the processing environment. This includes parameters like temperature uniformity, heating and cooling rates, vacuum level, and the composition of the process atmosphere.

Diversification allows for furnaces optimized for these specific needs. For example, a furnace for growing crystals will prioritize thermal stability, while one for brazing might prioritize high vacuum and rapid cycling.

A Response to Specific Industry Needs

Furnace manufacturers now work closely with industries like aerospace, electronics, and medical research to develop equipment for their unique applications. This co-development leads to market diversification, as a solution for one industry's problem becomes a new product category.

Key Market Impacts of Diversification

The move toward specialization has several clear and positive impacts on the market, benefiting both manufacturers who can differentiate their products and end-users who get better tools.

Enhanced Process Performance

Specialized furnaces deliver superior performance for their intended task. A furnace designed for a specific process will have its heating elements, insulation, and control systems optimized, leading to more repeatable and reliable results.

This translates into a stronger process performance, a key advantage noted in the market. Users can achieve their desired material properties with greater consistency.

Improved Equipment Quality and Reliability

When a furnace is designed without having to compromise for versatility, its components can be selected and integrated for maximum durability and reliability under a specific operational load. This focused design reduces failure points.

This commitment to task-specific quality is a primary reason why diversified product lines are associated with winning consumer trust and popularity. The equipment simply works better for its stated purpose.

Understanding the Trade-offs of Specialization

While diversification offers significant benefits, it is crucial to understand the trade-offs that come with highly specialized equipment.

Cost vs. Capability

A furnace optimized for a single, complex process is often more expensive than a general-purpose model. If you run multiple, less-demanding processes, purchasing several specialized furnaces can be a significant capital investment.

Reduced Flexibility

The primary trade-off for high performance is a loss of flexibility. A furnace engineered for high-vacuum annealing at 1200°C may be inefficient or incapable of performing a different process, such as rapid thermal processing in a hydrogen atmosphere.

Operational Complexity

Advanced, function-rich furnaces can come with a steeper learning curve. Operators may require additional training to effectively manage the sophisticated control systems and ensure processes are run correctly and safely.

Making the Right Choice for Your Goal

Selecting the correct vacuum tube furnace requires a clear understanding of your primary application and future needs.

- If your primary focus is cutting-edge R&D with novel materials: Choose a highly specialized furnace that provides the precise environmental control your specific process demands.

- If your primary focus is a multi-user or educational lab: A more general-purpose furnace with a wide operating window and user-friendly controls often provides the best long-term value and flexibility.

- If your primary focus is high-volume, single-process manufacturing: Prioritize a furnace built for repeatability, automation, and reliability to maximize uptime and product consistency.

By aligning your equipment choice with your core objective, you can leverage the market's diversification to acquire a tool that is a true solution to your specific challenge.

Summary Table:

| Aspect | Impact |

|---|---|

| Process Performance | Enhanced precision, repeatability, and reliability for specific applications |

| Equipment Quality | Improved durability and reduced failures due to task-specific design |

| Market Dynamics | Increased consumer trust, product differentiation, and capture of niche segments |

| Trade-offs | Higher cost, reduced flexibility, and potential operational complexity |

Unlock Precision for Your Lab with KINTEK's Custom Vacuum Tube Furnaces

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories—from R&D and education to high-volume production—with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're developing novel materials or optimizing manufacturing processes, our specialized equipment ensures superior performance, reliability, and efficiency.

Contact us today to discuss how we can tailor a solution for your specific challenges and elevate your material processing outcomes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability