The choice between a vertical and horizontal tube furnace hinges on four critical factors: temperature uniformity, contamination control, sample handling, and physical space. While both designs heat a sample within a tube, their orientation fundamentally changes the physics of heat transfer and particle management, making one far superior for high-precision applications.

The core decision is a trade-off between the simplicity of a horizontal furnace and the superior process control of a vertical furnace. Horizontal furnaces are workhorses for general-purpose heating, but vertical furnaces dominate high-precision fields like semiconductor fabrication due to their exceptional temperature uniformity and lower particle contamination.

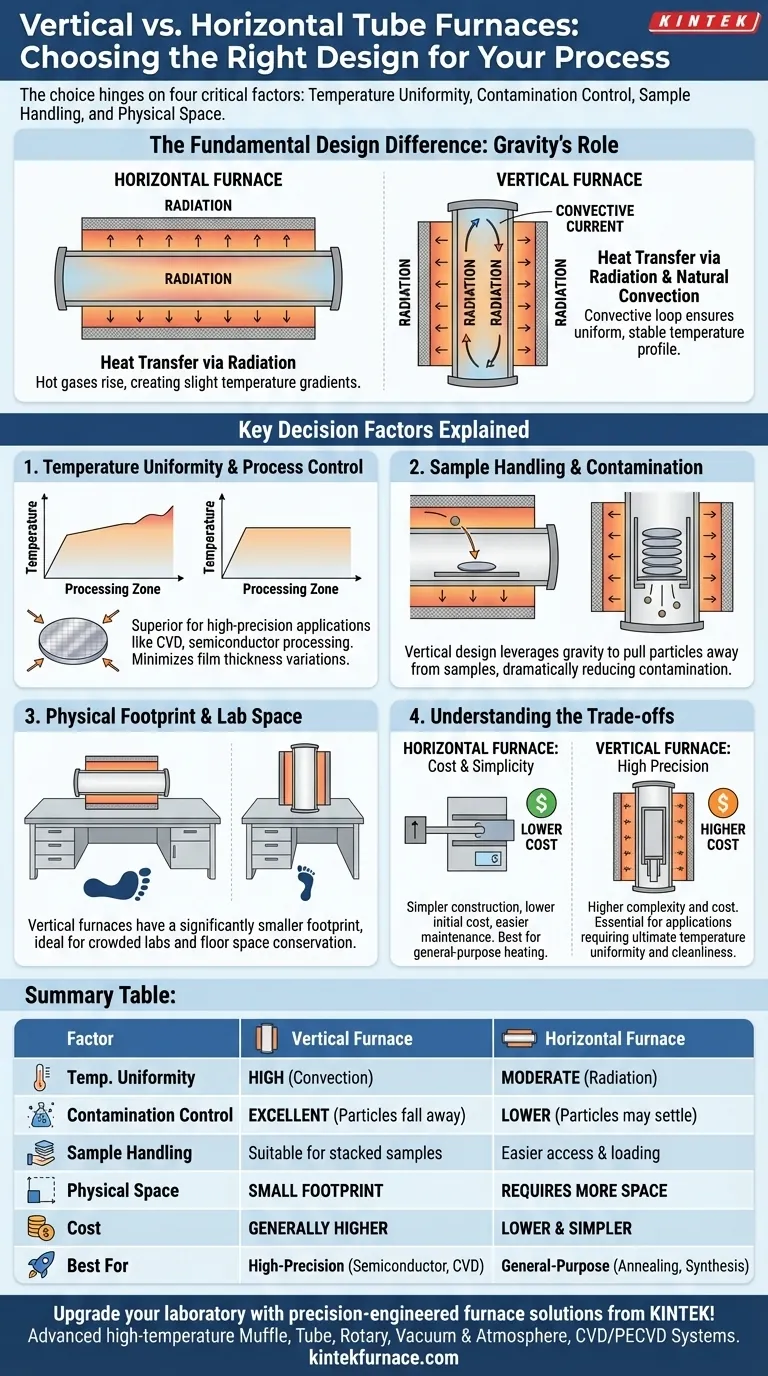

The Fundamental Design Difference: Gravity's Role

The orientation of the furnace tube is not just a matter of convenience; it directly influences the thermal environment inside. The primary difference comes down to the role of gravity in heat transfer.

How Horizontal Furnaces Work

In a horizontal furnace, heating elements surround the tube, transferring energy primarily through radiation. While effective, this can create slight temperature gradients.

Hotter gases tend to rise, creating a non-uniform thermal profile where the top of the tube can be slightly hotter than the bottom. This effect is minor for many applications but can be critical for others.

How Vertical Furnaces Work

A vertical furnace leverages gravity to its advantage. By orienting the tube vertically, heat transfer occurs through both radiation and natural convection.

As gas inside the tube is heated, it rises, cools, and then falls back down in a continuous, stable loop. This convective current actively mixes the atmosphere, resulting in a more uniform and stable temperature distribution along the processing zone.

Key Decision Factors Explained

Understanding the underlying physics allows us to evaluate the practical implications for your specific process.

Temperature Uniformity and Process Control

This is the most significant differentiator. The superior heat distribution in a vertical furnace is not just a theoretical benefit; it has a direct impact on results.

For processes like chemical vapor deposition (CVD) or semiconductor wafer processing, even minor temperature variations can lead to non-uniform film thickness and inconsistent device performance. Vertical furnaces mitigate this risk, which is why they have become the industry standard for these applications.

Sample Handling and Contamination

In a horizontal furnace, any microscopic particles generated during the process can fall directly onto the sample surface below them. This is a major source of defects in semiconductor manufacturing.

In a vertical furnace, samples are typically stacked on a "boat" or rack. Gravity pulls particles straight down, past the samples and away from their critical surfaces, dramatically reducing contamination.

Physical Footprint and Lab Space

This is a straightforward logistical consideration. A horizontal furnace requires a long, uninterrupted stretch of benchtop or floor space.

A vertical furnace has a much smaller footprint, making it an ideal choice for crowded labs or facilities where floor space is at a premium.

Understanding the Trade-offs

Choosing a vertical furnace is not always the correct answer. The simplicity and lower cost of horizontal models make them the right choice for many common laboratory tasks.

Cost and Simplicity

Horizontal furnaces generally have a simpler construction and loading mechanism. This often translates to a lower initial purchase price and potentially easier maintenance.

For applications that do not require ultimate precision, the added cost and complexity of a vertical furnace may not be justified.

Application Suitability

Horizontal furnaces are perfectly suited—and often preferred—for a wide range of tasks. These include general-purpose annealing, material synthesis, and bulk heat treatment where slight temperature variations or minor particle contamination are not a concern.

Accessibility

By design, the tube in a horizontal furnace is often easier to access, remove, and replace. This can be a minor convenience for routine cleaning or swapping out process tubes for different applications.

Making the Right Choice for Your Application

To select the correct furnace, you must first define the most critical variable for your process's success. Your choice should be driven by the demands of your application, not by a perceived universal superiority of one design over the other.

- If your primary focus is high-precision deposition or semiconductor processing: A vertical furnace is the necessary choice to achieve the required temperature uniformity and low particle contamination.

- If your primary focus is general-purpose materials testing, synthesis, or annealing: The cost-effectiveness and simplicity of a horizontal furnace make it the most practical and efficient tool for the job.

- If your primary focus is conserving laboratory floor space: A vertical furnace offers a significantly smaller footprint and is the clear winner for crowded environments.

Ultimately, matching the furnace's physical properties to the precision demands of your process is the key to a successful outcome.

Summary Table:

| Factor | Vertical Furnace | Horizontal Furnace |

|---|---|---|

| Temperature Uniformity | High (due to convection) | Moderate (radiation-based) |

| Contamination Control | Excellent (particles fall away) | Lower (particles may settle on samples) |

| Sample Handling | Suitable for stacked samples | Easier access and loading |

| Physical Space | Small footprint | Requires more bench space |

| Cost | Generally higher | Lower and simpler |

| Best For | High-precision (e.g., semiconductor, CVD) | General-purpose (e.g., annealing, synthesis) |

Upgrade your laboratory with precision-engineered furnace solutions from KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, enhancing efficiency and accuracy. Contact us today to discuss how we can support your specific applications and drive your research forward!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents