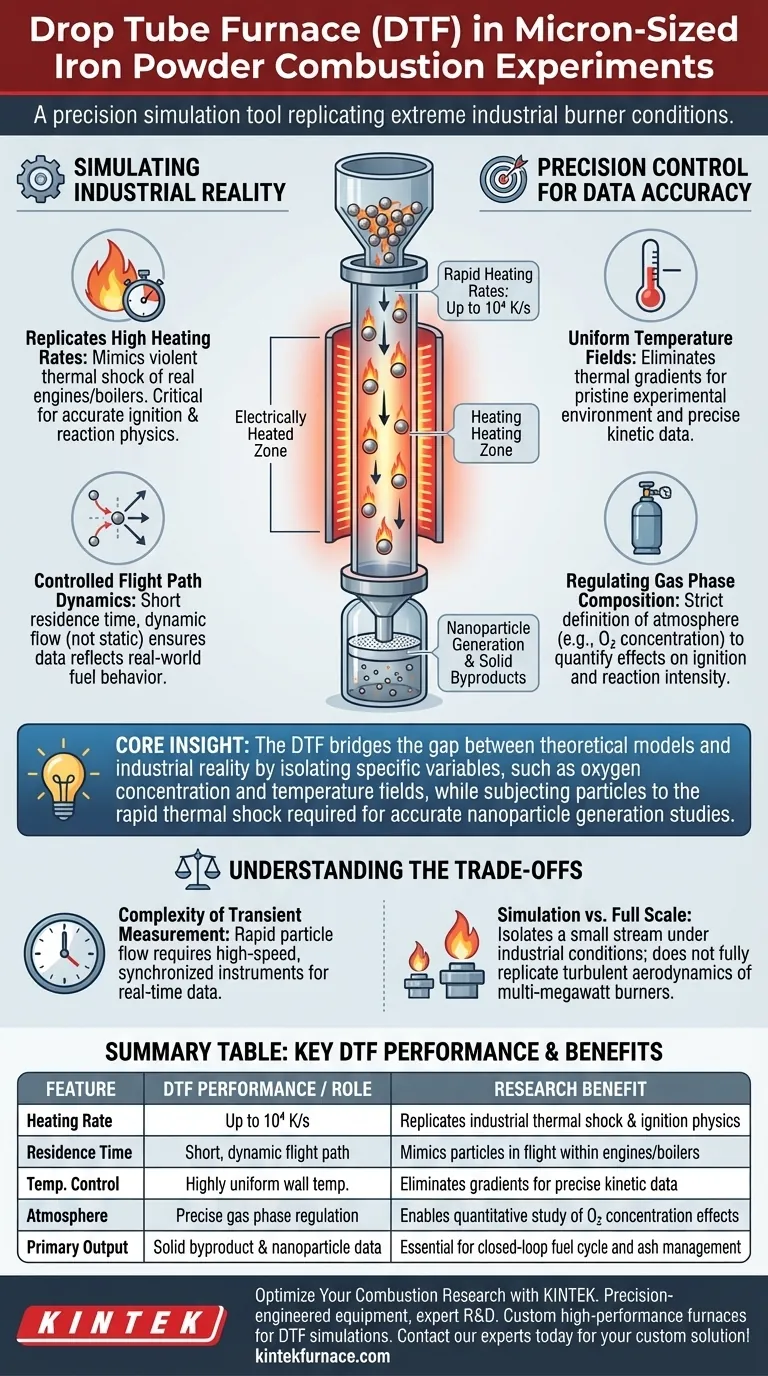

An Electrically Heated Drop Tube Furnace (DTF) serves as a precision simulation tool designed to replicate the extreme conditions of industrial burners within a controlled laboratory setting. Its primary role in micron-sized iron powder experiments is to provide a strictly controlled, high-temperature environment that achieves the rapid heating rates—up to $10^4$ K/s—necessary to mimic actual combustion physics.

Core Insight: The DTF bridges the gap between theoretical models and industrial reality by isolating specific variables, such as oxygen concentration and temperature fields, while subjecting particles to the rapid thermal shock required for accurate nanoparticle generation studies.

Simulating Industrial Reality

To understand the combustion of micron-sized iron powder, researchers cannot rely on standard, slow-heating laboratory ovens. They must replicate the violent thermal environment of a real engine or boiler.

Replicating High Heating Rates

Industrial burners subject fuel particles to immediate, intense heat. A DTF simulates this by achieving heating rates up to $10^4$ K/s. This rapid heating is critical because it fundamentally changes how the iron particle ignites and reacts compared to slow heating.

Controlled Flight Path Dynamics

The DTF utilizes a vertical reactor design. Iron particles are dropped through the heated zone, experiencing a short residence time similar to what occurs in a combustor. This ensures the data collected reflects the dynamic nature of fuel in flight, rather than a static sample.

Precision Control for Data Accuracy

The defining characteristic of a DTF is its ability to maintain a pristine experimental environment. This allows for the isolation of specific variables that affect combustion efficiency and byproduct formation.

Uniform Temperature Fields

The system precisely regulates the furnace wall temperature. This creates a highly uniform high-temperature reaction environment. By eliminating temperature gradients (cold or hot spots), researchers can be certain that the observed behaviors are due to the fuel chemistry, not equipment inconsistencies.

Regulating Gas Phase Composition

The DTF allows for the strict definition of the gas atmosphere surrounding the particle. This is essential for studying the quantitative effects of oxygen concentration. Researchers can adjust oxygen levels to observe exactly how they correlate with ignition delays and reaction intensity.

Nanoparticle Generation Analysis

Iron powder combustion produces solid byproducts, often in the form of nanoparticles. The DTF’s controlled environment is specifically used to study the generation of these nanoparticles. Understanding this process is vital for managing the "ash" or recyclable iron oxide products in a closed-loop fuel cycle.

Understanding the Trade-offs

While the DTF is the gold standard for dynamic combustion simulation, it presents specific challenges that researchers must manage.

Complexity of Transient Measurement

Because the particles are moving rapidly through the tube, gathering real-time data is more complex than in static experiments. The short residence time means that measurement instruments must be high-speed and precisely synchronized with the particle flow.

Simulation vs. Full Scale

While a DTF simulates the conditions of an industrial boiler (heating rate and temperature), it isolates a small stream of particles. It does not perfectly replicate the complex, turbulent aerodynamic interactions found in a full-scale, multi-megawatt burner, though it provides the fundamental kinetic data required to build those burners.

Making the Right Choice for Your Goal

The Drop Tube Furnace is a specialized instrument. Here is how to determine if it aligns with your specific research objectives.

- If your primary focus is Industrial Relevance: The DTF is required to validate that your iron fuel will ignite and burn efficiently under the rapid heating conditions ($10^4$ K/s) of a commercial system.

- If your primary focus is Byproduct Analysis: The DTF is the optimal tool for quantifying how specific oxygen levels influence the size and formation of nanoparticles during the flight of the particle.

Ultimately, the DTF is the critical link that translates fundamental iron powder chemistry into viable industrial energy solutions.

Summary Table:

| Feature | DTF Performance / Role | Research Benefit |

|---|---|---|

| Heating Rate | Up to $10^4$ K/s | Replicates industrial thermal shock and ignition physics |

| Residence Time | Short, dynamic flight path | Mimics particles in flight within engines or boilers |

| Temp. Control | Highly uniform wall temperature | Eliminates gradients for precise kinetic data |

| Atmosphere | Precise gas phase regulation | Enables quantitative study of oxygen concentration effects |

| Primary Output | Solid byproduct & nanoparticle data | Essential for closed-loop fuel cycle and ash management |

Optimize Your Combustion Research with KINTEK

Take your micron-sized iron powder studies to the next level with precision-engineered equipment. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, including specialized high-temperature furnaces tailored for Drop Tube Furnace (DTF) simulations.

Whether you are a researcher or an industrial developer, our customizable lab solutions provide the uniform temperature fields and rapid heating rates required for your unique needs. Empower your material science and energy research today—Contact our experts at KINTEK to discuss your custom furnace solution!

Visual Guide

References

- Di Chang, Yiannis A. Levendis. Effects of oxygen concentration on nanoparticle formation during combustion of iron powders. DOI: 10.1016/j.fuel.2025.135366

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is vacuum-sealed quartz tube encapsulation necessary? Ensure High-Purity Liquid Metal Spectral Analysis

- What role does a high-temperature tube furnace play in converting MXene derivatives into N-TiO2@NC? Unlock Precision Synthesis

- What core environmental conditions does an industrial high-temperature tube furnace provide for Ta4AlC3 synthesis?

- What is the function of the quartz glass tube within a coaxial DBD plasma reactor? Ensuring Stable Plasma Discharge

- What is a vertical tube furnace used for in semiconductor manufacturing? Essential for High-Precision Thermal Processing

- What are the different types of tubular furnaces? Choose the Right One for Your Lab

- How is the high-temperature environment of a tube furnace used for adsorbent regeneration? Achieve Precise Recovery

- How does the strong process performance of vacuum tube furnaces benefit users? Unlock Superior Quality and Efficiency