Vacuum-sealed quartz tube encapsulation is the fundamental standard for ensuring data accuracy when analyzing the vibrational spectra of liquid metals like germanium, bismuth, tin, and lead. This method is strictly necessary to prevent the immediate oxidation of the sample and to stop volatilization (evaporation) at the high temperatures required to keep these metals in a liquid state. Without this physical barrier, chemical reactions with the atmosphere would fundamentally alter the sample, rendering the resulting spectral data useless.

By isolating the liquid metal in a vacuum, researchers create a stable, chemically inert environment. This ensures that the measured vibrational modes reflect the intrinsic properties of the pure metal, rather than surface oxides or a degrading sample volume.

Preserving Sample Integrity at High Temperatures

To obtain accurate vibrational spectra, the sample must remain chemically pure and physically stable throughout the heating process.

Preventing Chemical Contamination

Liquid metals are highly reactive at elevated temperatures. Exposure to even trace amounts of oxygen can lead to the rapid formation of surface oxides.

These oxides have their own vibrational modes, which would obscure the signals from the pure metal. Vacuum sealing eliminates this variable entirely.

Controlling Sample Mass

Metals such as lead and tin have significant vapor pressures when molten. Without containment, the sample would undergo volatilization, slowly evaporating during the measurement.

The quartz tube maintains a constant sample mass. This stability is crucial for long-duration experiments where signal consistency is required.

Optimizing for Neutron Scattering

Beyond simple containment, the geometry of the quartz tube plays a vital active role in the quality of the measurement, particularly regarding neutron beam penetration.

Selecting the Right Diameter

The inner diameter of the quartz tube—typically between 3 to 4 mm—is not arbitrary. It is calculated based on the specific scattering cross-sections of the element being analyzed.

Researchers must match the tube size to the metal's interaction properties. A tube that is too wide for a highly scattering element would attenuate the beam, resulting in poor data.

Minimizing Background Interference

The quartz material itself interacts with the beam. However, by optimizing the tube's wall thickness and diameter relative to the sample volume, researchers can minimize the ratio of background noise to the sample signal.

Proper selection ensures that the container's contribution to the spectra can be easily subtracted during data analysis.

Understanding the Constraints

While necessary, using quartz encapsulation introduces specific challenges that must be managed to ensure valid results.

Background Subtraction is Mandatory

Quartz is not "invisible" to spectroscopic instruments. It generates its own vibrational signature.

You must perform a baseline measurement of the empty quartz tube. This background signal must be mathematically subtracted from the final data to isolate the liquid metal's spectrum.

Thermal Limits of Quartz

While quartz is robust, it has an upper thermal limit compared to other refractory materials.

For extremely high-temperature liquid metals, the softening point of the quartz tube itself becomes a limiting factor in the experimental design.

Ensuring Precision in Your Experiment

To maximize the quality of your vibrational spectra measurements, consider the following based on your specific objectives:

- If your primary focus is Chemical Purity: Ensure a high-quality vacuum seal is achieved prior to heating to completely eliminate oxide peaks in your spectra.

- If your primary focus is Signal Strength: Select the tube's inner diameter specifically based on the neutron scattering cross-section of your target element (e.g., smaller diameters for high scatterers).

rigorous sample environment control is the difference between measuring a metal and measuring its impurities.

Summary Table:

| Feature | Requirement | Benefit |

|---|---|---|

| Environment | Vacuum-sealed Quartz | Prevents oxidation and chemical contamination |

| Containment | Physical Barrier | Stops sample volatilization/mass loss at high temperatures |

| Tube Diameter | 3 - 4 mm (Optimized) | Maximizes neutron beam penetration and signal-to-noise ratio |

| Material | High-Quality Quartz | Minimizes background interference and provides thermal stability |

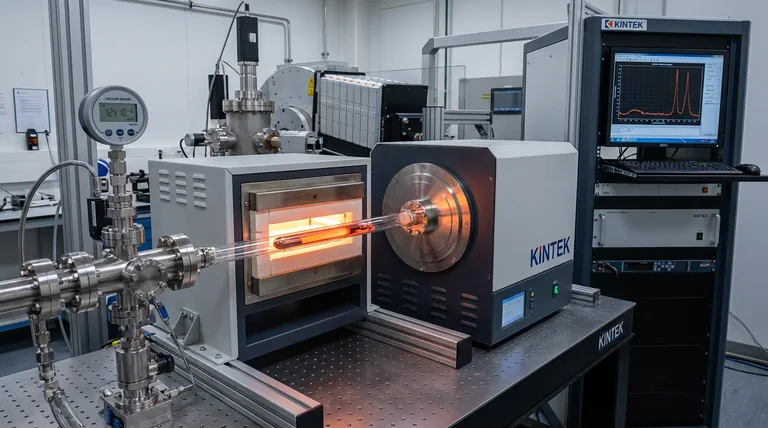

Precision Lab Solutions for Your Advanced Material Research

Achieving accurate spectral data starts with a superior sample environment. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of high-performance laboratory equipment, including Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are working with liquid metals or sensitive semiconductors, our high-temperature furnaces are fully customizable to meet your unique experimental needs.

Don't let impurities compromise your results. Contact KINTEK today to discover how our expert heating solutions can enhance your lab's efficiency and data precision!

References

- C. M. Bernal-Choban, Brent Fultz. Atomistic origin of the entropy of melting from inelastic neutron scattering and machine learned molecular dynamics. DOI: 10.1038/s43246-024-00695-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Magnesium Extraction and Purification Condensing Tube Furnace

- Ultra High Vacuum CF Flange Stainless Steel Sapphire Glass Observation Sight Window

- Ultra High Vacuum Observation Window KF Flange 304 Stainless Steel High Borosilicate Glass Sight Glass

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

People Also Ask

- Why is a high-temperature tube furnace utilized for the calcination of nano-zinc oxide? Master Microstructure Control

- What is the critical role of a programmable temperature tube reduction furnace? Achieve Precision Catalyst Activation

- What is the core function of a tube furnace in EN-LCNF synthesis? Unlock Precision Nanosheet Frameworks

- What is the purpose of using a tube furnace during the reduction phase of graphite flake surface treatment?

- What changes occur in materials processed in a tube furnace? Discover Physical, Chemical, and Heat Treatment Transformations

- What is a split tube furnace and what makes it versatile? Unlock Easy Access and Flexibility for Your Lab

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What are the drawbacks of corundum tube furnaces? Manage Costs, Visibility, and Thermal Risks