A high-vacuum tube furnace is essential because it creates an ultra-low pressure environment (below $10^{-4}$ Torr) that removes destructive contaminants like oxygen and moisture. At annealing temperatures reaching 1000 °C, this environment prevents the monolayer Transition Metal Dichalcogenides (TMDs) from oxidizing or physically disintegrating, allowing the process to focus solely on repairing crystal defects and adjusting doping states.

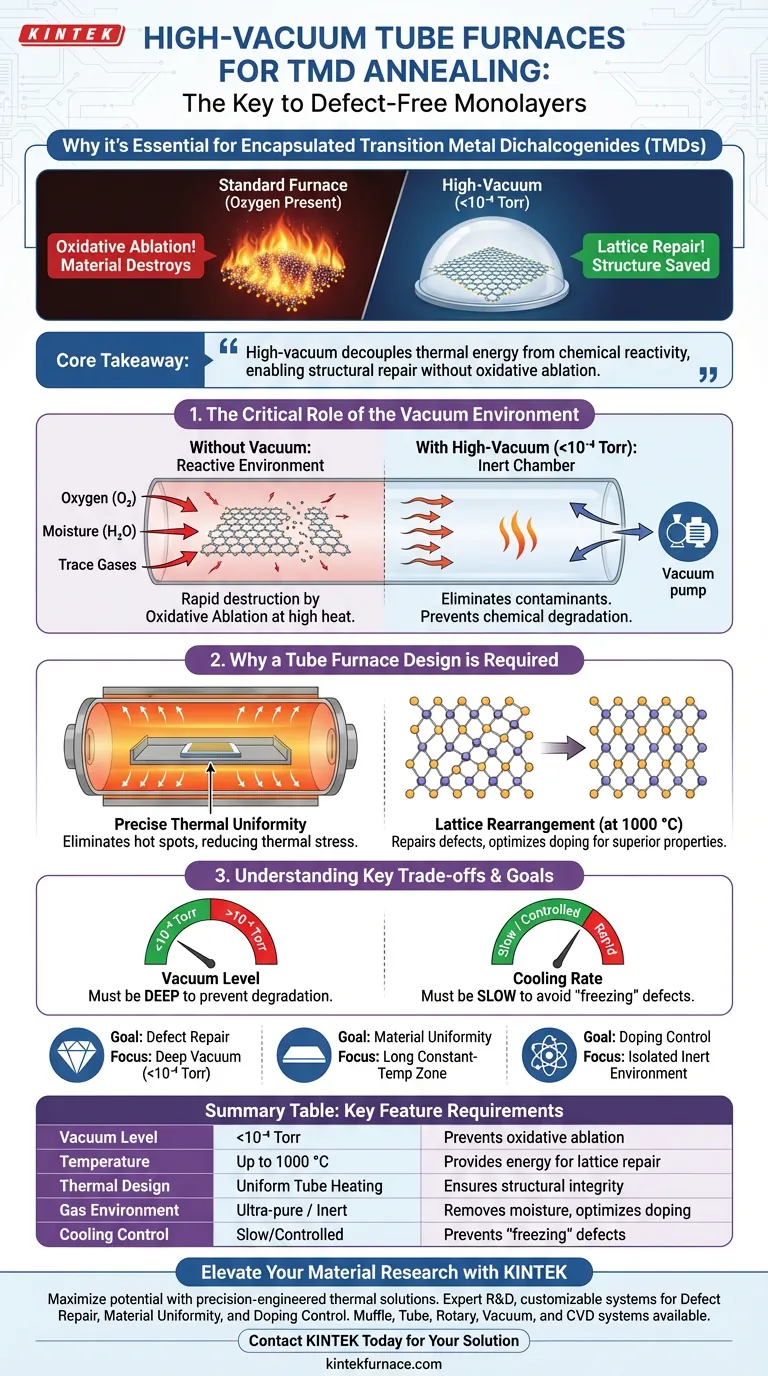

Core Takeaway High-temperature annealing of monolayer TMDs requires a delicate balance: high heat is needed to repair lattice defects, but that same heat triggers rapid destruction of the material if oxygen is present. A high-vacuum tube furnace solves this by decoupling thermal energy from chemical reactivity, enabling structural repair without oxidative ablation.

The Critical Role of the Vacuum Environment

Preventing Oxidative Ablation

Monolayer TMDs, such as WSe2, are atomically thin. This makes them exceptionally sensitive to their environment, particularly at high temperatures.

Without a high vacuum, introducing heat creates a reactive environment where residual oxygen attacks the material.

This leads to oxidative ablation, a process where the material essentially burns away or degrades chemically before the benefits of annealing can occur.

Eliminating Residual Contaminants

A standard furnace environment contains moisture and trace gases that act as impurities.

A high-vacuum system reduces internal pressure to below $10^{-4}$ Torr.

This threshold is critical because it effectively eliminates these contaminants, ensuring the chamber remains inert throughout the heating cycle.

Why a Tube Furnace Design is Required

Precise Thermal Uniformity

While the vacuum protects the chemistry, the tube furnace design protects the physical structure through uniform heating.

Tube furnaces provide a highly controlled thermal environment, which eliminates hot spots that could cause uneven processing or localized thermal stress.

This consistency is vital for maintaining the structural integrity of the delicate monolayer films across the entire substrate.

Facilitating Lattice Rearrangement

The ultimate goal of this annealing process is to improve the crystalline quality of the TMDs.

By maintaining a stable high temperature (up to 1000 °C) in a clean environment, the material undergoes lattice rearrangement.

This process repairs crystal defects and optimizes doping states, resulting in a higher quality bulk material with superior electronic and optical properties.

Understanding the Trade-offs

Vacuum Level vs. Material Stability

It is a common pitfall to assume that "low pressure" is sufficient. However, a vacuum that is not sufficiently deep (i.e., higher than $10^{-4}$ Torr) may still contain enough oxygen to degrade the monolayer at peak temperatures.

Heating vs. Cooling Rates

Achieving the target temperature is only half the battle. As noted in solid-phase synthesis principles, the cooling rate is equally critical.

Rapid cooling can "freeze" defects into the lattice, negating the benefits of the anneal.

A controlled, slow cooling process is often necessary to allow the lattice to settle into its lowest energy state, ensuring high crystallinity.

Making the Right Choice for Your Goal

To maximize the quality of your encapsulated monolayer TMDs, you must tailor your equipment usage to your specific objective.

- If your primary focus is Defect Repair: Ensure your vacuum system can reliably sustain pressures below $10^{-4}$ Torr to prevent oxidation while the lattice rearranges at 1000 °C.

- If your primary focus is Material Uniformity: Prioritize a tube furnace with a long constant-temperature zone to ensure the entire sample experiences the exact same thermal history.

- If your primary focus is Doping Control: Utilize the vacuum environment to isolate the material from environmental impurities, allowing for precise adjustment of the material's intrinsic doping states.

The success of high-temperature TMD annealing relies on the strict exclusion of oxygen coupled with precise thermal management.

Summary Table:

| Feature | Requirement for TMDs | Impact on Material Quality |

|---|---|---|

| Vacuum Level | < 10⁻⁴ Torr | Prevents oxidative ablation and chemical degradation |

| Temperature | Up to 1000 °C | Provides energy for lattice rearrangement and defect repair |

| Thermal Design | Uniform Tube Heating | Eliminates hot spots and ensures structural integrity |

| Gas Environment | Ultra-pure / Inert | Removes moisture and contaminants to optimize doping |

| Cooling Control | Slow/Controlled | Prevents "freezing" defects into the crystal lattice |

Elevate Your Material Research with KINTEK

Maximize the potential of your TMDs with precision-engineered thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable for your unique lab requirements. Whether you are focused on defect repair, material uniformity, or doping control, our systems provide the ultra-low pressure and thermal stability you need to succeed. Contact us today to find your custom furnace solution!

Visual Guide

References

- Huije Ryu, Gwan‐Hyoung Lee. Optical grade transformation of monolayer transition metal dichalcogenides <i>via</i> encapsulation annealing. DOI: 10.1039/d3nr06641j

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is the function of a high-temperature tube furnace in Cu(111) transformation? Achieve Atomic Precision

- Why is an Ultra-High Vacuum (UHV) compatible tube furnace necessary for beta-Ga2O3? Protect Your Semiconductor Integrity

- What role does the high-temperature vacuum tube furnace play in SiC/SiC pyrolysis? Essential Chemical Transformation

- Why must a specialized tube annealing furnace for REBCO joint preparation use two distinct zones? Find the Perfect Balance

- How does a tube furnace improve the crystal structure of zinc oxide thin films? Achieve High-Performance Crystallinity

- What factors affect the price of a horizontal tube furnace? Key Drivers from Temperature to Control Systems

- What is the importance of the nitrogen displacement step in a Tube Furnace? Secure High-Performance Ru-1 Catalysts

- How does a programmable temperature control tube furnace contribute to the formation of pore structures in biochar?