A high-temperature tube furnace provides the critical thermal and chemical environment necessary to prepare substrates for high-quality graphene synthesis. Specifically, it subjects copper foil substrates to extreme heat (around 1040°C) within a controlled atmosphere of argon and hydrogen to engineer the surface at a microscopic level before growth begins.

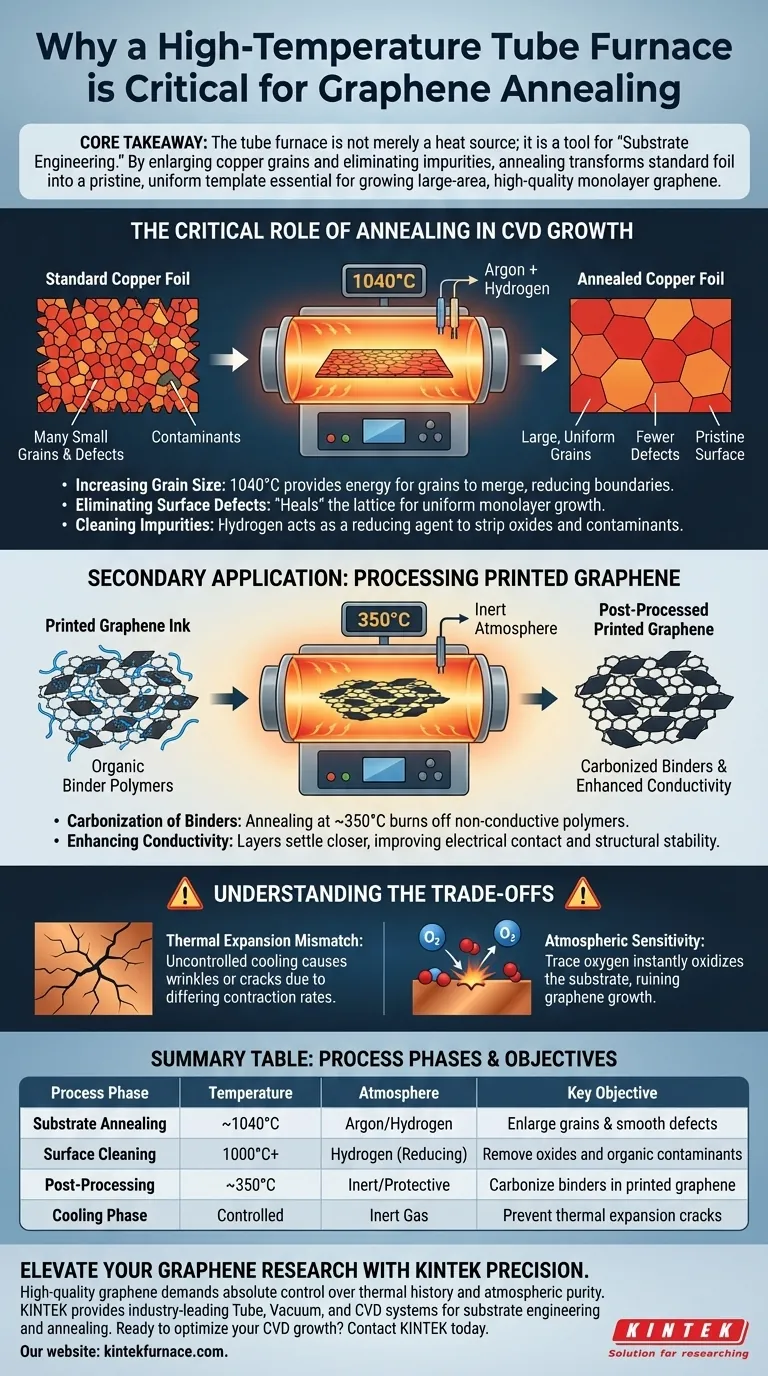

Core Takeaway The tube furnace is not merely a heat source; it is a tool for "substrate engineering." By enlarging copper grains and eliminating impurities, annealing transforms standard foil into a pristine, uniform template essential for growing large-area, high-quality monolayer graphene.

The Critical Role of Annealing in CVD Growth

The primary function of the tube furnace in Chemical Vapor Deposition (CVD) is to prepare the copper foil substrate. Since graphene is atomically thin, the quality of the substrate directly dictates the quality of the final material.

Increasing Grain Size

Standard copper foil consists of many small crystallographic "grains" with numerous boundaries.

Annealing at 1040°C provides the energy needed for these small grains to merge and grow larger.

This results in a surface with fewer grain boundaries, reducing defects in the graphene layer that eventually grows on top of it.

Eliminating Surface Defects

Raw copper foil often contains microscopic physical imperfections and dislocations.

The high-temperature treatment effectively "heals" the metal lattice, smoothing out these irregularities.

A smoother surface ensures that the graphene creates a uniform, continuous monolayer rather than a fragmented or multi-layered structure.

Cleaning Impurities

Copper surfaces are prone to oxidation and contamination from organic particles.

The tube furnace allows for a precise mix of gases, typically argon and hydrogen.

The hydrogen acts as a reducing agent, stripping away oxygen and cleaning impurities from the surface to ensure a pure chemical interface for growth.

Secondary Application: Processing Printed Graphene

While the primary application involves CVD growth, tube furnaces are also required for post-processing printed graphene structures.

Carbonization of Binders

Printed graphene inks often contain organic copolymer binders to maintain structure during printing.

Annealing at lower temperatures (around 350°C) in a protective atmosphere burns off or carbonizes these non-conductive binders.

Enhancing Conductivity

Once the excess organic components are decomposed, the graphene layers can settle closer together.

This improves the physical contact between layers, significantly boosting the macroscopic electrical conductivity and structural stability of the 3D-printed object.

Understanding the Trade-offs

While annealing is essential, it introduces specific variables that must be managed to avoid process failure.

Thermal Expansion Mismatch

Heating copper to 1040°C causes significant expansion.

If the cooling phase is not controlled precisely, the difference in contraction rates between the graphene and the copper can lead to wrinkles or cracks in the final graphene sheet.

Atmospheric Sensitivity

The "protective atmosphere" is unforgiving.

Even trace amounts of oxygen leaking into the tube furnace during the high-temperature phase can instantly oxidize the copper, ruining the substrate and preventing graphene growth entirely.

Making the Right Choice for Your Goal

The specific requirements for your tube furnace annealing process depend heavily on your fabrication method.

- If your primary focus is High-Quality CVD Growth: Prioritize a furnace capable of reaching 1040°C with precise hydrogen flow control to maximize copper grain size and surface purity.

- If your primary focus is Printed Graphene Electronics: Focus on a furnace with stable control at lower temperatures (350°C) to effectively remove binders without damaging the printed structure.

Success in graphene production is ultimately defined by how well you control the thermal history of your substrate.

Summary Table:

| Process Phase | Temperature | Atmosphere | Key Objective |

|---|---|---|---|

| Substrate Annealing | ~1040°C | Argon/Hydrogen | Enlarge copper grains & smooth surface defects |

| Surface Cleaning | 1000°C+ | Hydrogen (Reducing) | Remove oxides and organic contaminants |

| Post-Processing | ~350°C | Inert/Protective | Carbonize binders in printed graphene inks |

| Cooling Phase | Controlled | Inert Gas | Prevent thermal expansion cracks & wrinkles |

Elevate Your Graphene Research with KINTEK Precision

High-quality graphene synthesis demands absolute control over thermal history and atmospheric purity. KINTEK provides industry-leading Tube, Vacuum, and CVD systems designed to meet the rigorous demands of substrate engineering and annealing.

Whether you are focusing on maximizing copper grain size at 1040°C or carbonizing binders for printed electronics, our customizable high-temperature furnaces deliver the uniformity and gas precision your lab requires.

Ready to optimize your CVD growth? Contact KINTEK today to discuss how our expert R&D and manufacturing can support your unique material synthesis needs.

Visual Guide

References

- Gour Mohan Das, Mika Pettersson. Near‐Field Optical Nanopatterning of Graphene. DOI: 10.1002/smsc.202500184

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the technical advantages of using a vacuum tube furnace for S53P4-NO2 glass? Achieve 100% Amorphous Results

- What role does a tube furnace play in the growth of epitaxial thin films via PAD? Essential Guide to Precision Growth

- What are the advantages of using horizontal furnaces? Boost Efficiency and Uniformity in Batch Processing

- What is the function of a high-temperature tube furnace? Master Grain Growth for Microcrystalline Alloy Samples

- Why is a high-temperature tube furnace utilized for the calcination of nano-zinc oxide? Master Microstructure Control

- How does a tube furnace facilitate the structural stabilization of lignin? Mastering Lignin-to-Carbon Transformation

- Why is the design of a two-zone furnace critical for ZrTe5 crystal growth? Master CVT with Precision Control

- What is the primary purpose of using a high-temperature tube furnace? Master nZVI@BC Synthesis with Precision