The design of a two-zone furnace is critical because it creates the precise temperature gradient required to drive the Chemical Vapor Transport (CVT) process. For Zirconium Pentatelluride (ZrTe5), this configuration allows for independent control of a "source" zone and a "growth" zone, typically establishing a differential between 450°C and 500°C. This thermal gradient is the engine that propels transport agents, such as iodine, to carry raw materials across the quartz tube and deposit them as single crystals.

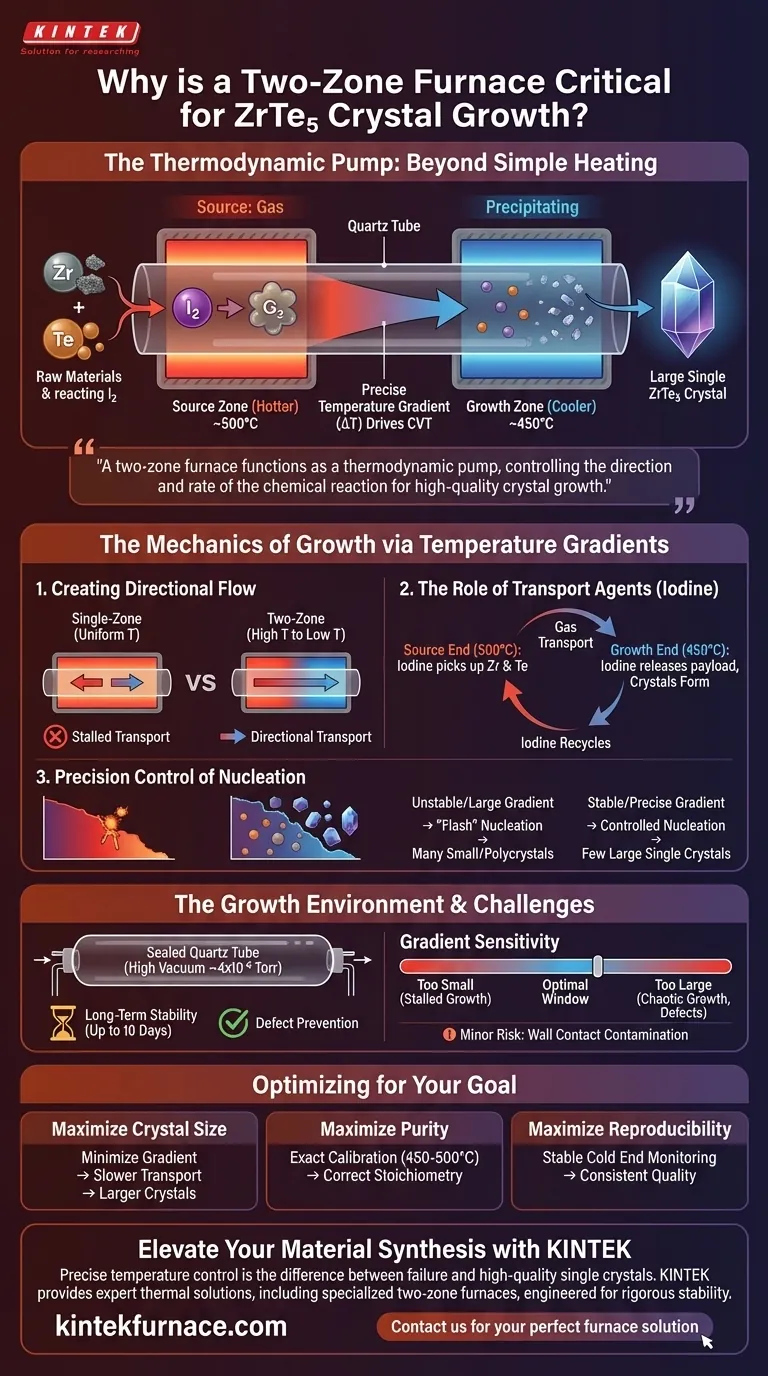

Core Takeaway A two-zone furnace functions as a thermodynamic pump rather than a simple heater. By strictly maintaining a temperature differential between two specific points, it controls the direction of the chemical reaction and the rate of nucleation, which are the determining factors in growing large, high-quality ZrTe5 crystals.

The Mechanics of Growth via Temperature Gradients

The production of ZrTe5 single crystals relies on the Chemical Vapor Transport (CVT) method. The two-zone furnace is the hardware solution designed to meet the strict physical requirements of this technique.

Creating a Directional Flow

A single-zone furnace creates a uniform temperature, which would result in equilibrium; no net transport of material would occur.

A two-zone furnace, however, establishes a high-temperature zone (Source) and a lower-temperature zone (Growth). This difference acts as the driving force, causing raw materials to react with the transport agent at one end and precipitate at the other.

The Role of Transport Agents

In the growth of ZrTe5, iodine is commonly used as a transport agent. The furnace's thermal profile dictates the iodine's behavior.

The gradient ensures that iodine picks up Zirconium and Tellurium at the hotter source end, travels as a gas, and releases the payload at the cooler growth end. Without this specific dual-zone control, the iodine would not cycle effectively.

Precision Control of Nucleation

The quality of a single crystal is defined by how it starts (nucleation) and how it continues to build (growth rate).

The two-zone design allows you to fine-tune the temperature difference. A stable, precise gradient prevents "flash" nucleation—where too many small crystals form at once. Instead, it encourages a slow, controlled precipitation, leading to large-sized crystals.

The Growth Environment

While the furnace provides the thermal engine, the reaction takes place inside a sealed vessel. Understanding the interplay between the furnace and the vessel is vital.

The Quartz Tube Assembly

The process occurs within a high-purity quartz tube, which serves as a sealed reaction vessel. The furnace must accommodate this tube while maintaining a vacuum environment of approximately 4×10⁻⁶ Torr.

The quartz tube is chemically stable, preventing reaction with the iodine or raw materials. The furnace must heat this tube to approximately 500°C without compromising the tube's structural integrity or the vacuum seal.

Duration and Stability

Crystal growth is not instantaneous. For similar materials, the process can take up to 10 days.

The critical design feature of a high-performance two-zone furnace is its ability to maintain the target gradient (e.g., 450–500°C) without fluctuation for extended periods. Instability in the furnace controller can lead to defects or layers in the ZrTe5 crystal structure.

Understanding the Trade-offs

While the two-zone CVT method is the standard for ZrTe5, it requires balancing several variables.

Gradient Sensitivity

The "perfect" gradient is a narrow window.

- If the gradient is too small: The transport rate is too slow, and growth may stall completely.

- If the gradient is too large: The transport rate becomes too fast, leading to rapid, chaotic growth. This results in polycrystals or structural defects rather than a single, high-quality crystal.

Wall Contact Contamination

Unlike "crucible-free" methods (such as the floating zone technique used for superconductors like BSCCO), the CVT method in a two-zone furnace involves physical contact between the crystal and the quartz tube.

While quartz is generally stable, there is always a minor risk of physical adhesion or strain when the crystal cools, which is a limitation inherent to the tube furnace design compared to floating zone methods.

Making the Right Choice for Your Goal

To maximize your success in growing ZrTe5, apply the furnace capabilities to your specific objective.

- If your primary focus is Crystal Size: Minimize the temperature gradient to the lowest functional limit. This slows the transport rate, reducing the number of nucleation sites and allowing individual crystals to grow larger over a longer period (e.g., 10+ days).

- If your primary focus is Crystal Purity: Ensure your furnace calibration is exact at the 450–500°C range. Deviations outside this window can alter the stoichiometry or trap the iodine transport agent within the crystal lattice.

- If your primary focus is Reproducibility: rigorous monitoring of the "Cold End" temperature is required. The stability of the crystallization zone is statistically more significant for final quality than the source zone.

Ultimately, the two-zone furnace transforms heat from a static condition into a dynamic tool, allowing you to dictate the precise speed and structure of crystal formation.

Summary Table:

| Feature | Requirement for ZrTe5 Growth | Impact on Crystal Quality |

|---|---|---|

| Temperature Gradient | Typically 450°C (Growth) to 500°C (Source) | Drives directional transport of raw materials via iodine agent. |

| Thermal Stability | Long-term maintenance (up to 10+ days) | Prevents structural defects and ensures uniform layer formation. |

| Nucleation Control | Precise $\Delta T$ adjustment | Low gradients reduce nucleation sites, leading to larger single crystals. |

| Atmosphere | Vacuum-sealed Quartz Tube (~4×10⁻⁶ Torr) | Ensures high purity and prevents contamination during growth. |

Elevate Your Material Synthesis with KINTEK

Precise temperature control is the difference between a failed experiment and a high-quality single crystal. KINTEK provides industry-leading thermal solutions backed by expert R&D and manufacturing.

Our specialized two-zone tube furnaces and customizable CVD, Vacuum, and Muffle systems are engineered to maintain the rigorous stability required for complex processes like ZrTe5 growth. Whether you need precise gradient control or a custom-built high-temperature solution, our team is ready to support your unique research needs.

Ready to optimize your crystal growth? Contact us today to find your perfect furnace solution!

Visual Guide

References

- Yueying Hou, Yan‐Feng Chen. Probing Anisotropic Quasiparticle Dynamics and Topological Phase Transitions in Quasi‐1D Topological Insulator ZrTe<sub>5</sub>. DOI: 10.1002/advs.202504798

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How does annealing in a laboratory tube furnace affect In2Se3 quality? Achieve Phase Stabilization & Purity

- What is the difference between a muffle furnace and a tube furnace? Choose the Right High-Temp Tool

- What are the specific functions of a vertical alumina tube reactor? Key Roles in Gasification Kinetics Research

- What are the advantages of decomposing tube furnaces? Achieve Precise Control and High Efficiency in Thermal Processes

- What critical function does a high-temperature tube furnace perform for FCNCuM@CNT? Achieve FCC Phase Precision

- What role does the calcination process in a high vacuum tube furnace play in the formation of Ce1-xTixO2-δ supports?

- Why is a tube furnace required for the debinding of kaolin ceramic green bodies? Ensure Structural Integrity & Control

- How does a tube furnace facilitate the annealing process for Antimony-doped ZnSe and PbSe thin films? Key Performance Tips