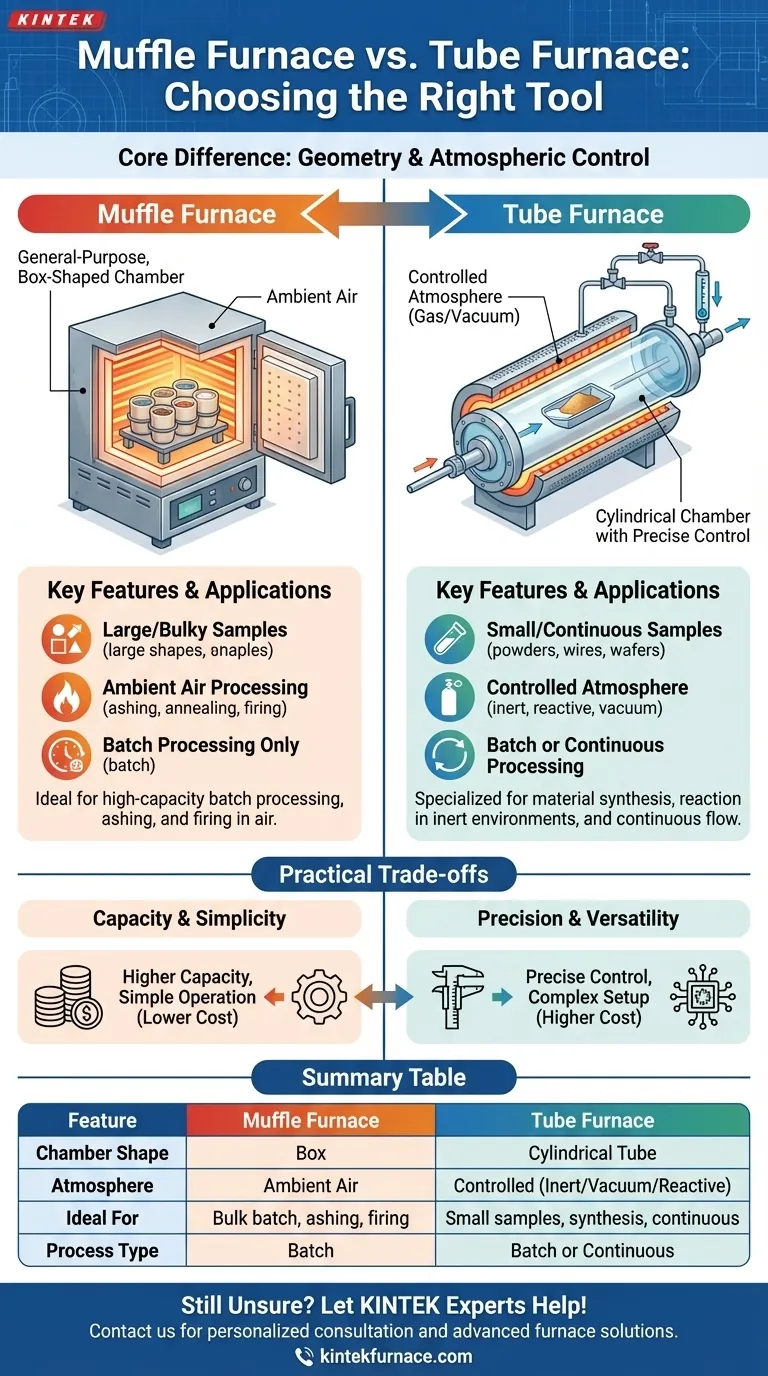

At its core, the difference between a muffle furnace and a tube furnace comes down to geometry and atmospheric control. A muffle furnace is a general-purpose, box-shaped chamber for heating static samples in ambient air, much like a high-performance oven. In contrast, a tube furnace uses a cylindrical chamber designed for processing smaller samples, often with precise control over the gas atmosphere or for continuous-flow applications.

The choice is not about which furnace is "better," but which is architecturally suited to your task. A muffle furnace is for bulk batch processing in air, while a tube furnace is for specialized processes requiring atmospheric control or a specific sample geometry.

The Fundamental Design Difference

The names "muffle" and "tube" describe the fundamental shape of the heating chamber, which in turn dictates their ideal use cases.

The Muffle Furnace: A High-Temperature Chamber

A muffle furnace is a self-contained, box-shaped furnace. The heating elements are built into the walls of an insulated chamber, creating a "muffle" that separates the sample from direct contact with the elements.

Samples remain fixed inside this chamber for the entire thermal cycle—heating, holding, and cooling. Their simple, robust design makes them workhorses for many industries.

The Tube Furnace: A Controlled Process Cylinder

A tube furnace is built around a long, cylindrical tube, typically made of ceramic or a high-temperature alloy. Heating elements surround this tube, creating a hot zone along its length.

Crucially, the ends of the tube can be sealed. This allows you to control the internal environment by pulling a vacuum or flowing a specific gas (like argon or nitrogen) through it, which is impossible in a standard muffle furnace.

Key Factors in Your Decision

Choosing between these two furnaces requires evaluating your sample, your process, and your need for atmospheric control.

Sample Size and Shape

A muffle furnace is the clear choice for processing large, bulky, or irregularly shaped items. Its box-shaped chamber offers significant internal capacity.

A tube furnace is restricted by the inner diameter of its process tube. It is ideal for small samples, powders, wafers, or continuous items like wires that can be passed through the cylinder.

Atmospheric Control

This is the most critical distinction. A muffle furnace operates in ambient air, making it perfect for applications like ashing, annealing metals that don't readily oxidize, or firing ceramics.

A tube furnace excels where the atmosphere must be precisely managed. It is essential for synthesizing materials that would be ruined by oxygen, performing reactions in an inert environment, or using reactive gases.

Process Type

Muffle furnaces are designed exclusively for batch processing. You load a batch of samples, run a thermal cycle, and unload them. The reference mentions this simple, single-door operation.

Tube furnaces are more versatile. They can be used for batch processing but are also uniquely suited for continuous processing, where a sample is slowly pulled through the hot zone. They can also create temperature gradients by using multiple heating zones along the tube.

Understanding the Practical Trade-offs

Each design comes with inherent compromises related to cost, complexity, and capability.

Capacity vs. Precision

As noted in the references, a muffle furnace generally provides more internal heating volume for your investment. They are built for capacity.

A tube furnace trades this raw capacity for process precision. The cost is concentrated on achieving excellent temperature uniformity in a smaller area and enabling strict atmospheric control.

Simplicity vs. Versatility

Muffle furnaces are remarkably simple to operate. You open the door, place the sample, and run the program. This makes them highly reliable and easy to maintain.

Tube furnaces demand more complex setup. Sealing the end flanges, managing gas flow lines, and operating vacuum pumps add steps to the process. This complexity is the price for their immense versatility.

Making the Right Choice for Your Goal

Select the furnace whose core design aligns with your material and processing objectives.

- If your primary focus is bulk heat treatment, ashing, or firing in air: A muffle furnace is your most direct and cost-effective solution.

- If your primary focus is material synthesis or processing under a controlled atmosphere: A tube furnace is the essential tool for preventing oxidation and enabling specific chemical reactions.

- If your primary focus is processing small, continuous samples like wires or powders: The cylindrical geometry and flow-through potential of a tube furnace are designed for this task.

Ultimately, selecting the right furnace is a matter of matching its fundamental design—box or tube—to the specific requirements of your material and process.

Summary Table:

| Feature | Muffle Furnace | Tube Furnace |

|---|---|---|

| Chamber Shape | Box | Cylindrical Tube |

| Atmosphere | Ambient Air | Controlled (Inert/Vacuum/Reactive) |

| Ideal For | Bulk batch processing, ashing, firing | Small samples, synthesis, continuous flow |

| Process Type | Batch | Batch or Continuous |

| Key Advantage | High capacity, simplicity | Atmospheric precision, versatility |

Still Unsure Which Furnace is Right for Your Application?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle Furnaces for high-capacity batch processing and Tube Furnaces for precise atmospheric control, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements.

Let our experts help you select the perfect furnace for your needs. Contact KINTEL today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control