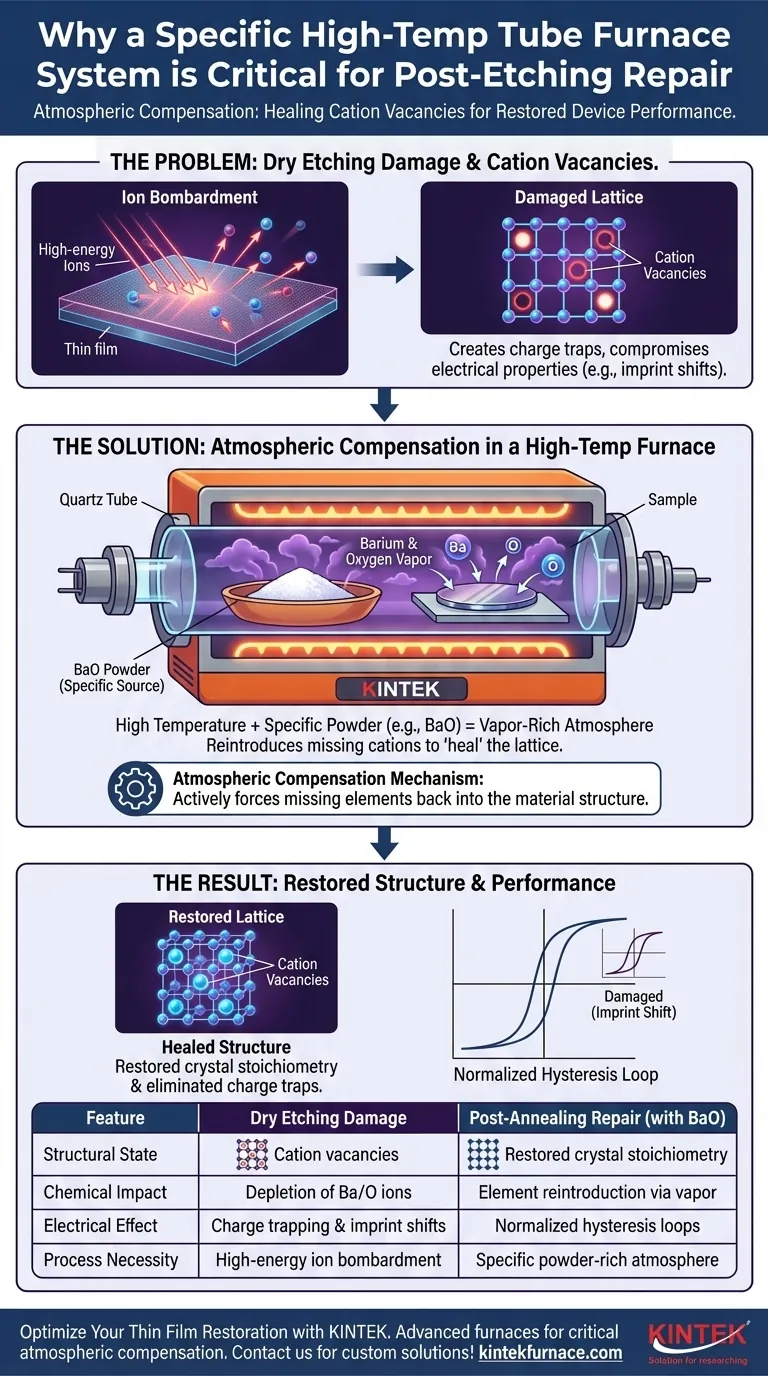

The repair process requires a specific chemical atmosphere, not just heat. High-energy dry etching damages thin films by physically knocking atoms out of the crystal lattice, creating "cation vacancies." A high-temperature tube furnace containing specific powders (such as Barium Oxide) is essential to create a vapor-rich environment that actively forces these missing elements back into the material to restore its structure.

The Core Mechanism: Atmospheric Compensation

Standard annealing cannot fix chemical depletion caused by ion bombardment. By using Barium Oxide powder to generate a Barium- and Oxygen-rich atmosphere, this process utilizes atmospheric compensation to reintroduce missing cations into the lattice, thereby eliminating charge traps and restoring electrical performance.

The Root Problem: Etching-Induced Damage

The Impact of Ion Bombardment

Dry etching processes, particularly ion milling, rely on high-energy bombardment to remove material. While effective for shaping, this physical impact damages the remaining crystal structure.

Formation of Cation Vacancies

The collision energy is often sufficient to strip away essential atoms from the film's surface and subsurface. This leaves behind cation vacancies—holes in the atomic lattice where positive ions should be.

Degradation of Electrical Properties

These vacancies act as defects that severely compromise the material's performance. Specifically, they create charge trapping states that interfere with electron movement and polarization.

In ferroelectric materials, these trapped charges cause "imprint shifts" in hysteresis loops, essentially biasing the material and preventing it from switching states cleanly.

The Solution: High-Temperature Atmospheric Repair

Creating the Compensation Environment

To repair this specific type of damage, simple thermal energy is insufficient. You must restore the chemical stoichiometry (balance) of the film.

This is achieved by placing a ceramic boat filled with Barium Oxide (BaO) powder alongside the sample inside a high-temperature tube furnace.

Reintroducing Missing Atoms

At high temperatures, the BaO powder sublimates or creates a vapor pressure, filling the tube environment with Barium and Oxygen.

This creates an atmosphere rich in the exact elements that were lost during etching. Driven by the high temperature, these atoms diffuse back into the film, filling the vacancies and "healing" the crystal lattice.

Restoring Device Reliability

Once the lattice is repaired, the charge trapping states are significantly reduced or eliminated. Consequently, the imprint shifts disappear, and the material's hysteresis loop returns to its expected, symmetrical behavior.

Understanding the Trade-offs

The Necessity of Specific Powders

You cannot substitute the specific powder source with inert gas or vacuum annealing. Without the BaO source, the atmosphere will lack the necessary cations to fill the vacancies, and the etching damage will remain permanent.

Thermal Budget Considerations

This process requires high temperatures to effectively volatilize the powder and drive diffusion. This imposes a strict thermal budget, meaning the underlying substrate and other device layers must be able to withstand this heat without degrading.

Making the Right Choice for Your Goal

To ensure the success of your post-etching recovery, align your process parameters with your specific repair needs:

- If your primary focus is eliminating imprint shifts: You must include the BaO powder source to correct the chemical stoichiometry of the lattice.

- If your primary focus is reducing charge traps: Ensure the furnace temperature is high enough to activate the atmospheric compensation mechanism fully.

By matching the annealing atmosphere to the chemical loss caused by etching, you convert a damaged film back into a high-performance device.

Summary Table:

| Feature | Dry Etching Damage | Post-Annealing Repair (with BaO) |

|---|---|---|

| Structural State | Cation vacancies & lattice damage | Restored crystal stoichiometry |

| Chemical Impact | Depletion of Barium/Oxygen ions | Element reintroduction via vapor |

| Electrical Effect | Charge trapping & imprint shifts | Normalized hysteresis loops |

| Process Necessity | High-energy ion bombardment | Specific powder-rich atmosphere |

Optimize Your Thin Film Restoration with KINTEK

Don't let dry etching damage compromise your material's performance. KINTEK provides the advanced high-temperature tube furnaces and precision heating solutions required for critical atmospheric compensation processes.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your unique thermal budget and chemical repair needs. Whether you are addressing cation vacancies or complex lattice healing, our systems ensure the uniform atmosphere required for device reliability.

Ready to enhance your lab's efficiency? Contact us today to discuss your custom furnace needs!

Visual Guide

References

- Yizhe Jiang, Lane W. Martin. Effect of fabrication processes on BaTiO3 capacitor properties. DOI: 10.1063/5.0203014

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does a benchtop tube furnace ensure the quality of silicon nitride green bodies? Master Debinding Precision

- How can tube furnaces be configured for different laboratory needs? Optimize Your Lab's Thermal Processes

- What role does automation play in horizontal electric furnaces? Boost Precision and Efficiency in Thermal Processing

- What are the key challenges in using tubular furnaces for materials science? Overcome Temperature, Uniformity, and Contamination Issues

- How are tube furnaces utilized in environmental testing? Key Applications for Analysis and Remediation

- Why is temperature control technology important in tube furnaces? Ensure Precision and Efficiency in Your Lab

- What is the function of a high-temperature tube furnace in the preparation of Black-TiO2? Enhance Photocatalytic Power

- Why is vacuum-sealed quartz tube encapsulation necessary? Ensure High-Purity Liquid Metal Spectral Analysis