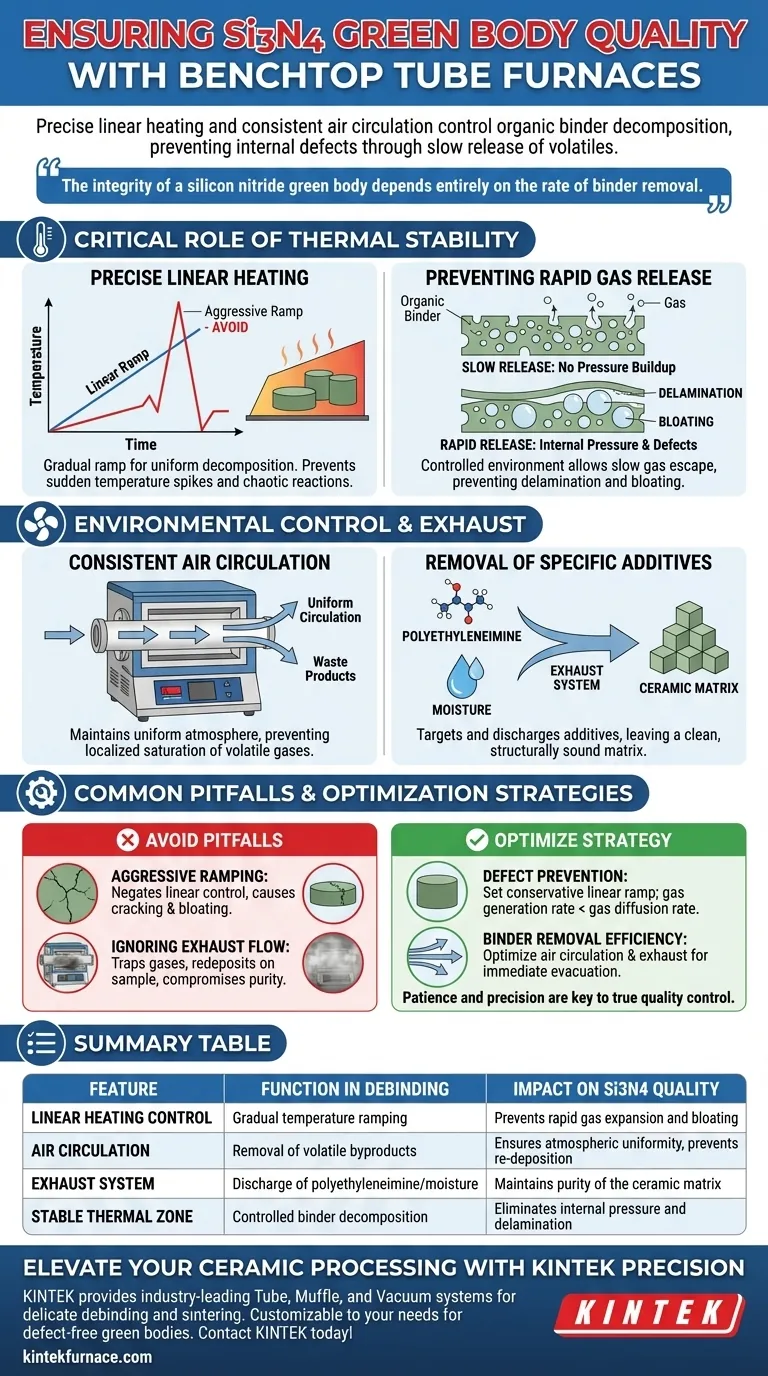

A benchtop tube furnace ensures quality by delivering precise linear heating and consistent air circulation to control the decomposition of organic binders like polyethyleneimine. This stable thermal environment allows for the slow release of volatiles and residual moisture, preventing rapid gas expansion that would otherwise cause internal defects.

The integrity of a silicon nitride green body depends entirely on the rate of binder removal. A benchtop tube furnace provides the controlled environment necessary to decompose organic matter without generating the internal pressure that leads to structural failure.

The Critical Role of Thermal Stability

Precise Linear Heating

The primary challenge in processing silicon nitride (Si3N4) green bodies is the sensitivity of organic additives to heat. A benchtop tube furnace utilizes a precise linear heating control system to gradually increase temperature.

This gradual ramp allows for the uniform decomposition of organic binders. It prevents sudden temperature spikes that could trigger chaotic chemical reactions within the material.

Preventing Rapid Gas Release

When organic matter decomposes, it turns into gas. If the temperature rises too quickly, this gas is generated faster than it can escape the porous ceramic structure.

The furnace's stable temperature control ensures the gas is released slowly. This directly prevents internal pressure buildup, which is the root cause of delamination (layer separation) and bloating (bubble formation).

Environmental Control and Exhaust

Consistent Air Circulation

Heating is only half of the equation; removing the waste products is the other. The furnace maintains a consistent air circulation environment throughout the heating zone.

This circulation is vital for carrying away the byproducts of decomposition. It ensures that the atmosphere around the green body remains uniform, preventing localized saturation of volatile gases.

Removal of Specific Additives

The process is specifically designed to target organic additives, such as polyethyleneimine, and residual moisture.

By effectively discharging these elements through an exhaust system, the furnace leaves behind a clean, structurally sound ceramic matrix ready for the final sintering phase.

Common Pitfalls to Avoid

The Danger of Aggressive Ramping

A common mistake is attempting to speed up the debinding process by increasing the heating rate.

While a tube furnace is capable of high temperatures, applying heat too aggressively negates the benefits of linear control. This almost inevitably leads to the very defects—cracking and bloating—you are trying to prevent.

Ignoring Exhaust Flow

Relying solely on temperature without ensuring proper exhaust function can trap decomposition gases.

If the exhaust system is obstructed or the air circulation is insufficient, volatized organics may re-deposit on the sample or create an unpredictable chemical environment, compromising the purity of the silicon nitride.

Optimizing Your Debinding Strategy

To maximize the quality of your silicon nitride components, align your furnace settings with your specific material requirements.

- If your primary focus is Defect Prevention: Set a conservative linear heating ramp to ensure the rate of gas generation never exceeds the rate of gas diffusion.

- If your primary focus is Binder Removal Efficiency: Ensure the air circulation and exhaust systems are fully optimized to immediately evacuate volatized polyethyleneimine and moisture.

True quality control in ceramics begins with the patience and precision applied during the debinding phase.

Summary Table:

| Feature | Function in Debinding | Impact on Si3N4 Quality |

|---|---|---|

| Linear Heating Control | Gradual temperature ramping | Prevents rapid gas expansion and bloating |

| Air Circulation | Removal of volatile byproducts | Ensures atmospheric uniformity and prevents re-deposition |

| Exhaust System | Discharge of polyethyleneimine/moisture | Maintains purity of the ceramic matrix |

| Stable Thermal Zone | Controlled binder decomposition | Eliminates internal pressure and delamination |

Elevate Your Ceramic Processing with KINTEK Precision

Don't let aggressive heating or poor exhaust compromise your silicon nitride components. KINTEK provides industry-leading Tube, Muffle, and Vacuum systems designed specifically for the delicate debinding and sintering phases. Backed by expert R&D and manufacturing, our laboratory high-temperature furnaces are fully customizable to meet your unique material requirements, ensuring defect-free green bodies and superior structural integrity.

Ready to optimize your debinding strategy? Contact KINTEK today to consult with our experts!

Visual Guide

References

- Masanori Horie, Rodney W. Trice. Slip casting porous silicon nitride for high‐temperature radar frequency radomes. DOI: 10.1111/ijac.70016

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What role does a tube furnace play in producing activated carbon? Master Walnut Shell Activation for High Adsorption

- How does the use of a tube furnace enhance cellulose-amine materials? Unlock Superior Porosity & Surface Area

- How do the components of a tube furnace contribute to its overall performance? Optimize Your Lab's Heat Processing Efficiency

- How does the temperature curve control in a quartz tube sintering furnace affect Ag-P electrode in-situ doping?

- Why is a Horizontal Tube Furnace used for the torrefaction of Refuse Derived Fuel (RDF)? Boost Fuel Efficiency Now

- What is the function of the quartz glass tube within a coaxial DBD plasma reactor? Ensuring Stable Plasma Discharge

- How do tube furnaces and isolation valves simulate TCOP experiments? Expert Setup for Thermochemical Oxygen Pumps

- Why use stainless steel or nickel foil liners in tube furnaces? Protect Your Equipment During KOH Activation