Precise thermal regulation is critical because CZTSSe thin films possess a narrow stability window where slight overheating leads to irreversible material degradation. Specifically, temperatures exceeding 300 °C can trigger phase decomposition or amorphization, ruining the crystalline structure necessary for effective semiconductor performance.

The synthesis of CZTSSe is a delicate thermal balancing act; a high-precision furnace is the only tool that can navigate the narrow range between necessary formation heat and destructive decomposition, ensuring reproducible optoelectronic results.

The Critical Role of Temperature Stability

Achieving high-quality CZTSSe films is not just about reaching a target temperature; it is about maintaining it with absolute rigor. The material's sensitivity dictates that the synthesis environment must be free from significant thermal fluctuations.

Navigating the Decomposition Threshold

CZTSSe materials are thermally volatile relative to other semiconductors. The primary reference indicates that these films are prone to phase decomposition when temperatures rise above 300 °C.

A standard furnace with wide thermal swings could inadvertently cross this threshold. High-precision equipment ensures the temperature remains strictly within the safe processing zone (typically between 100 °C and 350 °C), preserving the chemical integrity of the film.

Preventing Amorphization

Beyond chemical decomposition, excessive heat can lead to amorphization. This is a process where the orderly crystalline lattice breaks down into a disordered structure.

For a semiconductor like CZTSSe, crystallinity is paramount. If the material becomes amorphous due to thermal overshoot, it loses the specific electronic properties required for efficient photon-to-electron conversion.

Achieving Single-Phase Formation

The ultimate goal of the synthesis process is to create a "single-phase" material. This means the entire film consists of the desired CZTSSe crystal structure without contaminating byproducts or secondary phases.

Uniformity is Key

To achieve a pure phase, the heat distribution across the sample must be perfectly uniform. Cold spots can lead to incomplete reaction, while hot spots cause decomposition.

High-precision furnaces provide a stable thermal envelope. This ensures that every distinct area of the thin film experiences the exact same thermal history, leading to a homogenous, single-phase layer.

Reproducible Optoelectronic Performance

Scientific research and industrial application both rely on reproducibility. If you cannot make the same film twice, the process is unviable.

By eliminating thermal variables, a precision furnace ensures that the optoelectronic properties—such as bandgap and efficiency—remain consistent from batch to batch. This reliability is the foundation of scalable device fabrication.

Facilitating Gradient Experiments

Researchers often need to determine the exact optimal temperature for synthesis. This is done through gradient experiments, where the temperature varies controllably across a range.

Fine-Tuning Material Properties

The primary reference highlights the use of gradient experiments between 100 °C and 350 °C. A high-precision furnace can maintain a specific, controlled temperature gradient.

This allows scientists to test multiple synthesis temperatures simultaneously on a single substrate. It accelerates the discovery of the precise thermal point where the material performs best without crossing into decomposition.

Understanding the Trade-offs

While high-precision furnaces are essential for quality, they introduce specific challenges that must be managed.

Equipment Complexity vs. Throughput

High-precision units often utilize complex control algorithms and slower ramp rates to prevent overshoot. This can increase the total processing time compared to rougher, rapid-heating industrial ovens.

strict Calibration Requirements

The "precision" of the furnace is only as good as its calibration. Because the margin for error with CZTSSe (around the 300 °C mark) is so small, sensors must be calibrated frequently. A drifted thermocouple can lead to batches being unknowingly processed in the decomposition zone.

Making the Right Choice for Your Goal

Selecting the right thermal processing strategy depends on whether you are in the discovery phase or the production phase.

- If your primary focus is Process Optimization: Prioritize a furnace with controllable gradient capabilities to rapidly identify the exact stability limit between 100 °C and 350 °C.

- If your primary focus is Batch Consistency: Prioritize a furnace with exceptional thermal uniformity and overshoot protection to ensure no part of the film ever exceeds the 300 °C decomposition threshold.

Success with CZTSSe synthesis is defined by your ability to respect the material's thermal limits through precision engineering.

Summary Table:

| Feature | Impact on CZTSSe Synthesis | Benefit |

|---|---|---|

| Precise Thermal Control | Prevents decomposition above 300 °C | Preserves chemical integrity |

| Uniform Heat Distribution | Eliminates hot and cold spots | Ensures single-phase formation |

| Stable Thermal Envelope | Maintains crystalline lattice | Prevents amorphization |

| Gradient Capabilities | Fine-tunes material properties | Accelerated process optimization |

| Overshoot Protection | Avoids accidental thermal spikes | Guaranteed batch-to-batch consistency |

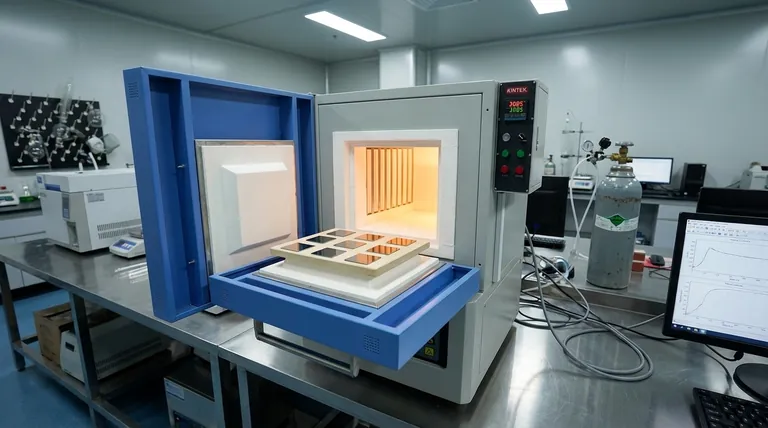

Optimize Your CZTSSe Synthesis with KINTEK Precision

Don't let thermal instability ruin your semiconductor research. KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems specifically engineered to handle narrow stability windows.

Backed by expert R&D and precision manufacturing, our lab high-temp furnaces are fully customizable to meet your unique thin-film requirements. Whether you are navigating the 300 °C decomposition threshold or conducting complex gradient experiments, KINTEK ensures reproducible optoelectronic results every time.

Ready to elevate your material quality?

Contact KINTEK Today to Consult with our Experts

Visual Guide

References

- Akin Olaleru, Edwin Mapasha. Unveiling the Influence of Annealing Temperature on Properties of CZTSSe Nanocrystals. DOI: 10.1002/apxr.202500016

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the function of a high-temperature calcination furnace? Mastering Pr3+:CaGdF2 Nanopowder Precursor Prep

- How do resistance furnaces and glass fiber heating mantles collaborate in distillation? Ensure Optimal Vapor Stability

- How does an industrial high-temperature furnace simulate the blast furnace reduction environment? Achieve 30% Reduction

- What heating mechanisms are available for retort furnaces? Choose Electric or Gas for Optimal Performance

- What are the common applications of program-controlled atmosphere furnaces? Essential for High-Temp Material Processing

- What is the primary purpose of an inert oven? Protect Materials from Oxidation in Heating

- What are the heating mechanisms used in retort furnaces? Choose the Right Heating for Your Lab or Industry

- What environmental benefits do controlled atmosphere furnaces offer? Reduce Waste and Boost Efficiency