In essence, a program-controlled atmosphere furnace is used whenever a material's properties must be precisely manipulated in a high-temperature environment free from the influence of air. They are critical tools for the high-temperature sintering, annealing, brazing, and heat treatment of advanced materials across the metallurgical, electronics, ceramics, and materials science sectors.

The primary purpose of an atmosphere furnace is not just to generate heat, but to meticulously control the chemical environment during the heating process. This control is the key to preventing unwanted reactions like oxidation and achieving the specific, repeatable material properties required for advanced applications.

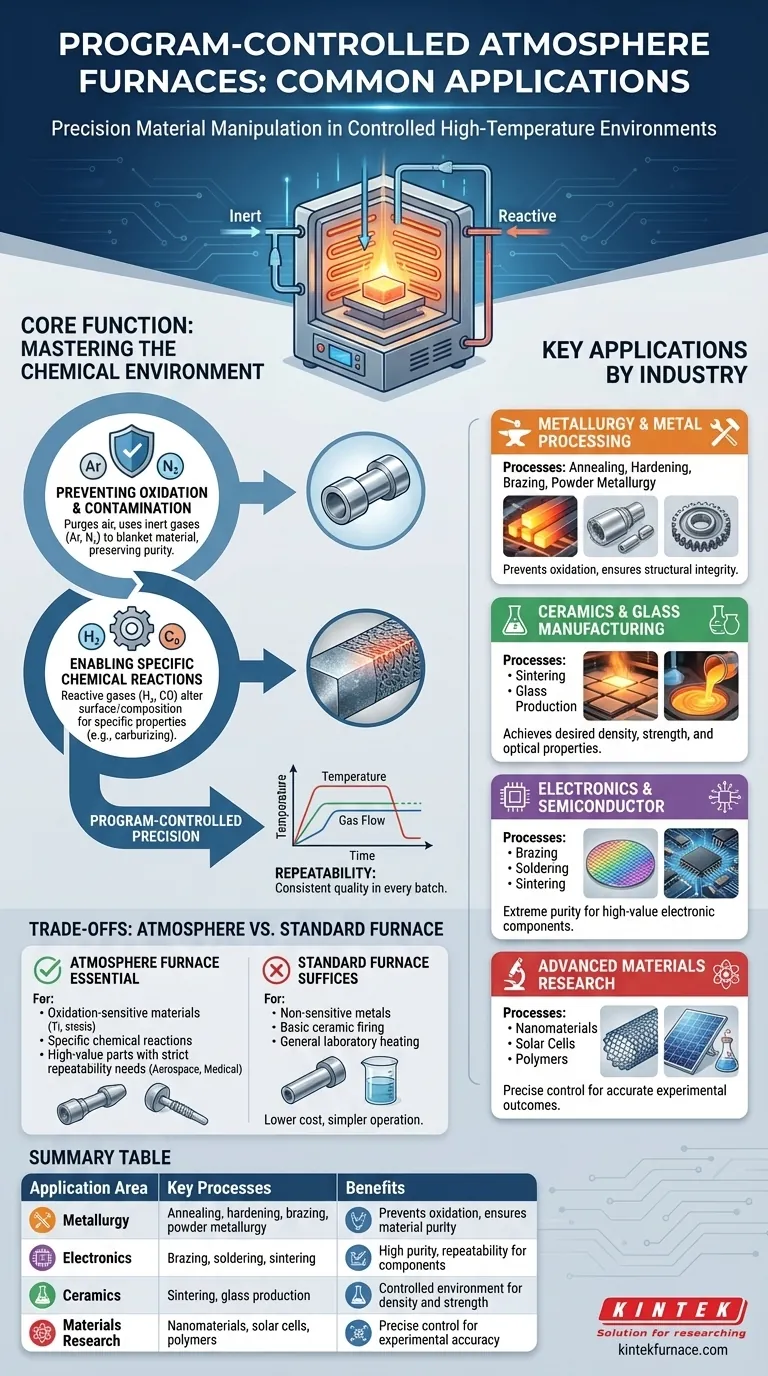

The Core Function: Mastering the Chemical Environment

At high temperatures, most materials are highly reactive with the oxygen and moisture present in ambient air. A program-controlled atmosphere furnace solves this by creating a sealed chamber where the air is replaced with a specific, tightly controlled gas or gas mixture.

Preventing Oxidation and Contamination

Many advanced metals, such as titanium alloys, and powdered metals will rapidly oxidize when heated in air. This oxidation can ruin the material's structural integrity and performance.

An atmosphere furnace purges the chamber of air and fills it with an inert gas, like argon or nitrogen. This blankets the material, protecting it from unwanted chemical reactions and ensuring its purity is maintained throughout the thermal process.

Enabling Specific Chemical Reactions

In some processes, the goal is not to prevent a reaction but to cause a specific one. The furnace's atmosphere can be composed of reactive gases to alter the material's surface or composition.

For example, a hydrogen atmosphere can be used as a reducing agent to remove oxides from a surface before brazing. A carbon-rich atmosphere can be used for carburizing, a process that hardens the surface of steel parts.

Ensuring Process Repeatability

The "program-controlled" aspect is what guarantees precision and repeatability, which are non-negotiable in industrial manufacturing.

These furnaces use sophisticated controllers to execute pre-programmed temperature and atmosphere profiles. This automation ensures that every part in every batch experiences the exact same conditions, leading to consistent quality in products like medical devices or semiconductor components.

Key Applications by Process and Industry

The ability to control both temperature and chemistry makes these furnaces indispensable in several high-tech fields.

Metallurgy and Metal Processing

This is a primary application area. Processes include annealing (softening metals), hardening (strengthening them), and brazing (joining parts, especially aluminum automotive components). It is also essential for powder metallurgy, where metal powders are sintered into solid parts.

Ceramics and Glass Manufacturing

Advanced ceramics require precise sintering to achieve desired density and mechanical strength. An atmosphere furnace provides the clean, controlled environment needed. It is also used in specialized glass production to achieve specific optical properties.

Electronics and Semiconductor Production

The electronics industry relies on atmosphere furnaces for manufacturing components with extreme purity. Key processes include brazing electronic components, soldering in a controlled environment, and sintering materials for semiconductor devices and displays.

Advanced Materials Research

For materials scientists, these furnaces are fundamental research tools. They are used to develop and test new materials, including nanomaterials, components for solar cells, and high-performance polymer materials, where even minor atmospheric variations could alter the experimental outcome.

Understanding the Trade-offs: Atmosphere vs. Standard Furnace

Choosing the correct furnace is a critical decision based on your material's needs and your process goals.

When an Atmosphere Furnace is Essential

You must use an atmosphere furnace for any process involving oxidation-sensitive materials like titanium or certain steels. It is also required for processes that depend on a specific chemical environment, such as reduction or carburization, and for manufacturing high-value components where process repeatability is paramount (e.g., aerospace, medical, electronics).

When a Simpler Furnace Suffices

For basic scenarios like heat treating non-sensitive metals, simple ceramic firing, or general laboratory sample heating, a standard "box" furnace that operates in air is often sufficient. These furnaces are simpler to operate and have a lower initial cost, making them a more practical choice when precise atmospheric control is not a critical variable.

Making the Right Choice for Your Goal

Ultimately, the decision comes down to the chemical requirements of your material at high temperatures.

- If your primary focus is manufacturing advanced components (e.g., semiconductors, medical devices): An atmosphere furnace is essential for the required purity and process control.

- If your primary focus is processing oxidation-sensitive metals (e.g., titanium alloys, powder metals): You need an atmosphere furnace to prevent material degradation and ensure final part integrity.

- If your primary focus is general heat treatment or basic research: A standard furnace is likely more cost-effective if your materials are not sensitive to air.

Choosing the right furnace is about matching the tool to the material's specific chemical needs at high temperatures.

Summary Table:

| Application Area | Key Processes | Benefits |

|---|---|---|

| Metallurgy | Annealing, hardening, brazing, powder metallurgy | Prevents oxidation, ensures material purity |

| Electronics | Brazing, soldering, sintering | High purity, repeatability for components |

| Ceramics | Sintering, glass production | Controlled environment for density and strength |

| Materials Research | Nanomaterials, solar cells, polymers | Precise control for experimental accuracy |

Unlock the full potential of your materials with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with custom solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for sintering, annealing, brazing, and more. Contact us today to discuss how we can enhance your process efficiency and achieve superior results!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas