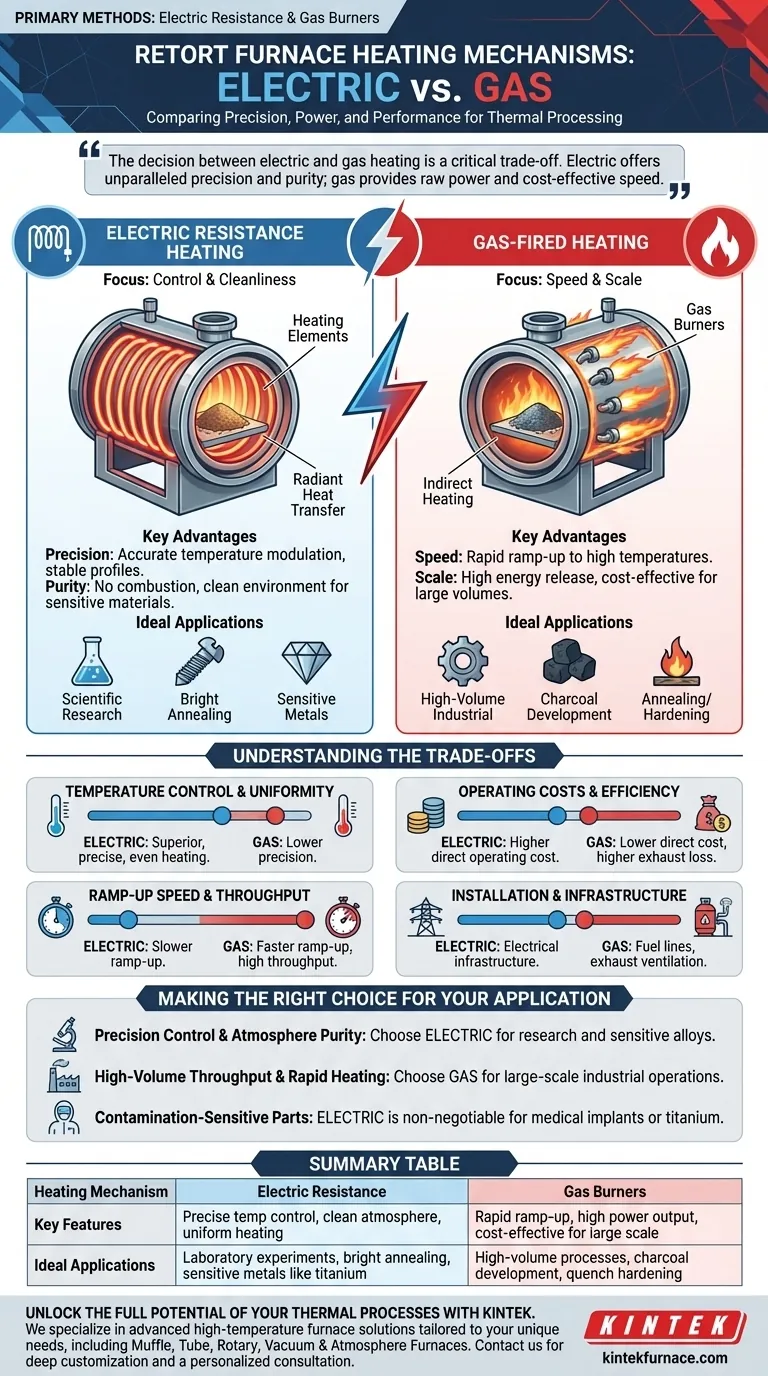

At their core, retort furnaces are heated using one of two primary methods: electric resistance heaters or gas burners. The choice between these mechanisms is not arbitrary; it fundamentally shapes the furnace's performance, precision, and suitability for specific thermal processes.

The decision between electric and gas heating is a critical trade-off. Electric furnaces offer unparalleled precision and atmosphere purity, ideal for sensitive materials and research, while gas-fired furnaces provide raw power and cost-effective speed for high-volume industrial applications.

A Closer Look at Electric Heating

Electric heating is the method of choice when control and cleanliness are paramount. It relies on passing an electric current through high-resistance materials to generate heat.

How Electric Resistance Heaters Work

These heaters, often made from specialized alloys or ceramics, are positioned around the retort chamber. When electricity flows through them, their inherent resistance causes them to heat up, transferring thermal energy to the retort and its contents primarily through radiation.

Key Advantages: Precision and Purity

The primary benefit of electric heating is precise temperature control. The power input can be modulated with extreme accuracy, enabling stable temperatures and programmable heating profiles. Because there is no combustion, this method also ensures a clean processing environment, which is critical for preventing contamination.

Ideal Applications

Electric heating is dominant in laboratory settings for scientific experiments and material synthesis. It is also essential for industrial processes that demand strict atmospheric control, such as the bright annealing of stainless steel and the heat treatment of sensitive metals like titanium.

Understanding Gas-Fired Heating

Gas-fired heating is the workhorse of many large-scale industrial operations. This method uses the combustion of natural gas or propane to generate the required thermal energy.

The Principle of Gas Burners

Burners are strategically placed to heat the exterior of the retort vessel. The hot combustion gases transfer heat to the retort wall, which in turn heats the material inside. This is an indirect heating method that leverages the high energy density of fossil fuels.

Key Advantages: Speed and Scale

Gas burners can release enormous amounts of energy quickly, allowing for rapid ramp-up to high temperatures. For continuous, high-throughput industrial processes like charcoal development or large-scale annealing, the lower cost of gas compared to electricity often makes it the more economical choice.

Ideal Applications

Gas heating is common in heavy industrial applications where speed and operating cost are more critical than minute temperature precision. Processes like quench hardening, tempering, and annealing in large rotary retort furnaces often rely on gas for its power and efficiency.

Understanding the Trade-offs: Electric vs. Gas

Choosing a heating mechanism involves balancing competing priorities. Your application's specific needs will determine which set of trade-offs is acceptable.

Temperature Control and Uniformity

Electric heating is superior for temperature control and uniformity. The ability to distribute heating elements precisely around the retort allows for exceptionally even heating and minimizes hot spots, which is crucial for sensitive components.

Operating Costs and Efficiency

Gas heating generally has a lower direct operating cost, as natural gas is often cheaper per unit of energy than electricity. However, the overall efficiency can be lower due to heat lost in exhaust gases.

Ramp-Up Speed and Throughput

Gas-fired furnaces typically heat up faster due to their high power output, making them ideal for operations where maximizing material throughput is the primary goal.

Installation and Infrastructure

Electric furnaces require significant electrical infrastructure, while gas furnaces require fuel lines, storage, and exhaust ventilation. The existing infrastructure at a facility can heavily influence the decision.

Making the Right Choice for Your Application

Your selection should be guided by the primary goal of your thermal process.

- If your primary focus is precision control and atmosphere purity: Choose an electric retort furnace for its unparalleled temperature stability and clean operation, ideal for research or processing sensitive alloys.

- If your primary focus is high-volume throughput and rapid heating: A gas-fired furnace is likely the better choice due to its fast ramp-up times and lower energy costs at industrial scale.

- If you are processing contamination-sensitive parts like titanium or medical implants: The clean, controlled environment of an electric furnace is non-negotiable.

Ultimately, understanding the strengths of each heating system empowers you to select the right tool for your specific engineering or scientific objective.

Summary Table:

| Heating Mechanism | Key Features | Ideal Applications |

|---|---|---|

| Electric Resistance | Precise temperature control, clean atmosphere, uniform heating | Laboratory experiments, bright annealing, sensitive metals like titanium |

| Gas Burners | Rapid ramp-up, high power output, cost-effective for large scale | High-volume processes, charcoal development, quench hardening |

Unlock the Full Potential of Your Thermal Processes with KINTEK

Choosing the right heating mechanism is crucial for your lab's success. At KINTEK, we specialize in providing advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by exceptional R&D and in-house manufacturing.

- For Precision and Purity: Our electric furnaces offer unmatched temperature control and clean environments, perfect for sensitive materials and research.

- For Power and Efficiency: Our gas-fired furnaces deliver rapid heating and cost savings, ideal for high-throughput industrial applications.

With our strong deep customization capability, we can precisely meet your experimental requirements, ensuring optimal performance and reliability. Don't settle for less—contact us today to discuss how KINTEK can enhance your laboratory's capabilities and drive innovation.

Contact us now for a personalized consultation!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing