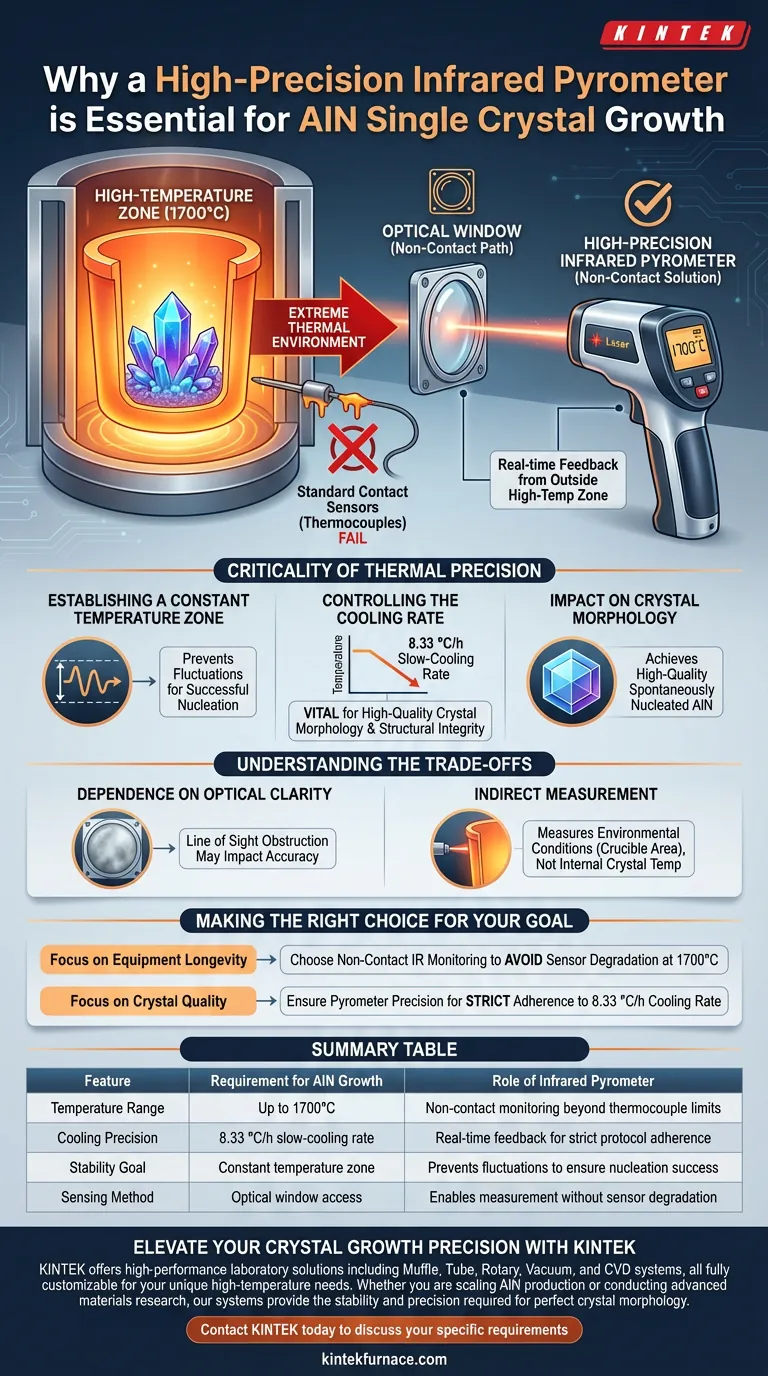

Extreme thermal environments demand non-contact solutions. In the synthesis of Aluminum Nitride (AlN) single crystals, process temperatures reach 1700°C, rendering standard contact sensors like thermocouples unusable due to the harsh conditions. A high-precision infrared pyrometer is the only viable instrument to monitor the crucible through an optical window, ensuring the strict thermal stability required for successful crystallization.

Success in AlN growth hinges on maintaining a precise constant temperature zone within a hostile 1700°C environment. The infrared pyrometer provides the necessary real-time, non-contact feedback to execute critical slow-cooling protocols, directly determining the final crystal quality.

Overcoming Physical Limitations

The 1700°C Barrier

Standard contact measurement tools fail in the extreme heat required for AlN growth. Conventional thermocouples cannot withstand direct contact with the growth environment at 1700°C.

The Optical Solution

To bypass the limitations of physical contact, the system utilizes an optical window. This allows the high-precision infrared pyrometer to monitor the crucible area in real-time from outside the high-temperature zone.

The Criticality of Thermal Precision

Establishing a Constant Temperature Zone

The growth of single crystals requires an incredibly stable environment. The pyrometer ensures the experiment remains within a precise constant temperature zone, preventing fluctuations that could disrupt nucleation.

Controlling the Cooling Rate

The most critical phase of the process is the cooling stage. The pyrometer provides the data necessary to maintain a specific slow cooling rate of 8.33 °C/h.

Impact on Crystal Morphology

This strict adherence to the slow cooling rate is not arbitrary. It is vital for achieving high-quality crystal morphology in spontaneously nucleated AlN, ensuring the structural integrity of the final product.

Understanding the Trade-offs

Dependence on Optical Clarity

Because the measurement relies on an optical window, the system is dependent on a clear line of sight. Any obstruction or clouding of the window could potentially impact the accuracy of the temperature reading.

Indirect Measurement

The pyrometer monitors the crucible area, rather than the crystal itself. Operators must understand that they are measuring the environmental conditions surrounding the growth, rather than the internal temperature of the crystal.

Making the Right Choice for Your Goal

To optimize your AlN growth setup, prioritize your instrumentation based on your specific operational needs:

- If your primary focus is Equipment Longevity: Choose non-contact infrared monitoring to avoid the degradation and failure common with physical sensors at 1700°C.

- If your primary focus is Crystal Quality: Ensure your pyrometer offers enough precision to strictly enforce the 8.33 °C/h cooling rate, as this dictates the final morphology.

Precision monitoring is the bridge between a volatile high-temperature environment and a perfect crystalline structure.

Summary Table:

| Feature | Requirement for AlN Growth | Role of Infrared Pyrometer |

|---|---|---|

| Temperature Range | Up to 1700°C | Non-contact monitoring beyond thermocouple limits |

| Cooling Precision | 8.33 °C/h slow-cooling rate | Real-time feedback for strict protocol adherence |

| Stability Goal | Constant temperature zone | Prevents fluctuations to ensure nucleation success |

| Sensing Method | Optical window access | Enables measurement without sensor degradation |

Elevate Your Crystal Growth Precision with KINTEK

High-quality Aluminum Nitride (AlN) crystals require rigorous thermal control that standard equipment simply cannot provide. Backed by expert R&D and manufacturing, KINTEK offers high-performance laboratory solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable for your unique high-temperature needs.

Whether you are scaling AlN production or conducting advanced materials research, our systems provide the stability and precision required for perfect crystal morphology. Contact KINTEK today to discuss your specific requirements with our technical team and discover how our customizable furnaces can optimize your laboratory results.

Visual Guide

References

- Xiaochun Tao, Zhanggui Hu. Growth of Spontaneous Nucleation AlN Crystals by Al-Base Alloy Evaporation in Nitrogen Atmosphere. DOI: 10.3390/cryst14040331

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- Why is a low expansion coefficient beneficial for graphite heating elements? Achieve Superior Thermal Stability

- What are the characteristics of aluminum for heating applications? Unlock Efficient Heat Transfer Solutions

- What role do molybdenum or tungsten evaporation boats play in PVD for fluorides? Ensuring Ultra-Pure Deposition

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- How do alumina ceramic tubes improve temperature control and safety in high-temperature furnaces? Enhance Precision and Safety Up to 1800°C

- What safety features do ceramic infrared heaters include? Ensure Safe, Efficient Heating for Your Space

- What materials are commonly used in high-temperature heating elements? Explore Top Choices for Durability and Efficiency

- How high-precision thermocouples monitor PTC-TEG-MOF systems? Enhance Thermal Gradient & Energy Harvesting Analysis