In short, a low expansion coefficient is beneficial for graphite heating elements because it ensures they maintain their shape and structural integrity when subjected to extreme temperature changes. This dimensional stability prevents mechanical stress, cracking, and premature failure, leading to a longer and more reliable service life.

The core issue isn't just expansion, but the repeated stress caused by thermal cycling. A low coefficient of thermal expansion (CTE) makes a material resistant to this stress, directly translating into higher reliability and longevity for the heating element.

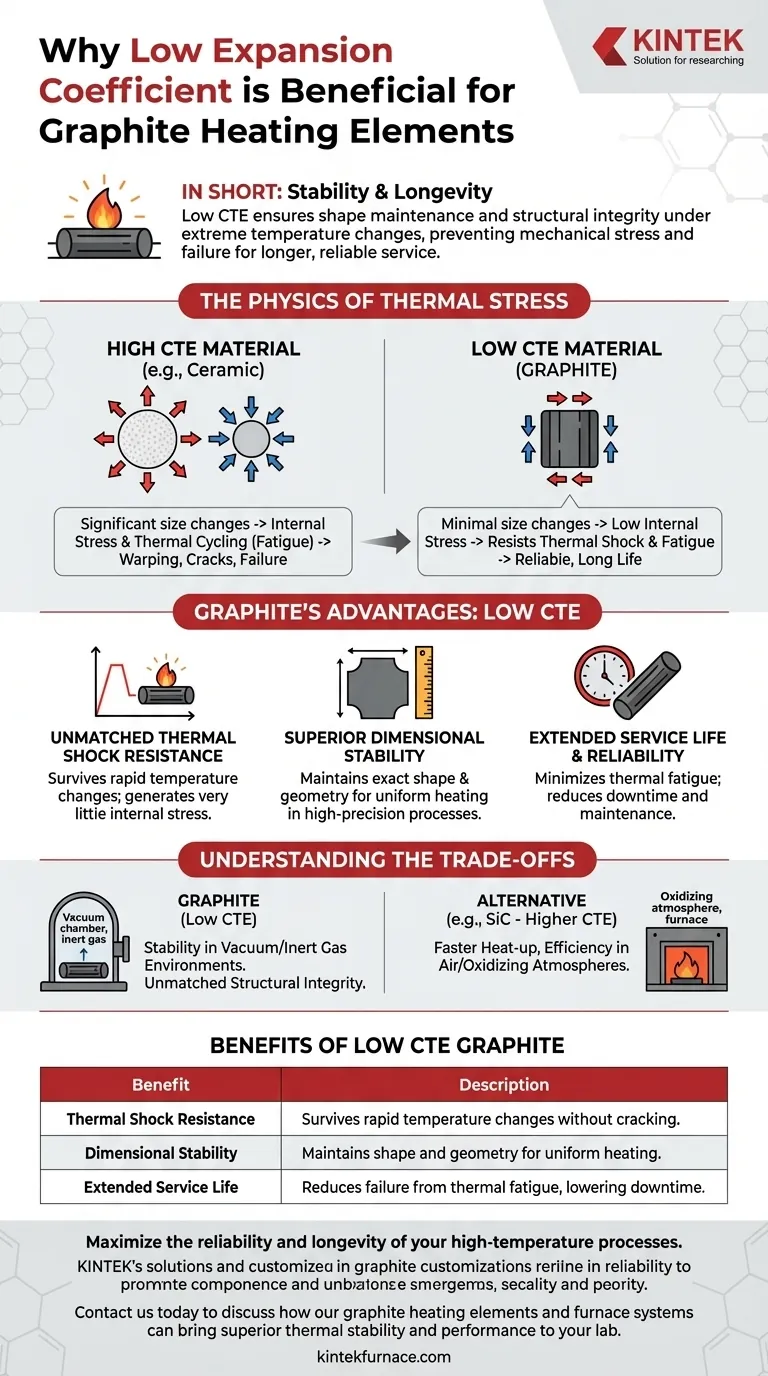

The Physics of Thermal Stress

Heating elements, by their nature, undergo constant and often rapid changes in temperature. Understanding how materials react to this is key to designing a reliable system.

What is Thermal Expansion?

Nearly all materials expand when heated and contract when cooled. The coefficient of thermal expansion (CTE) is the specific measurement of how much a material's size changes for every degree of temperature change.

A material with a high CTE will experience significant size changes, while a material with a low CTE, like graphite, will change very little.

The Problem with Expansion: Internal Stress

When a heating element expands, its movement can be constrained by the surrounding structure or even by cooler parts of the element itself. This resistance to free expansion creates immense internal mechanical stress.

When the element cools, it contracts, creating tensile stress. This constant cycle of pushing and pulling is known as thermal cycling.

How Thermal Cycling Leads to Failure

This repeated stress is a form of mechanical fatigue. Think of bending a paperclip back and forth; even though each bend is small, the repeated stress eventually causes it to weaken and break.

For a heating element with a high CTE, each heat-up and cool-down cycle is like one of those bends. Over time, this fatigue leads to microscopic cracks that grow until the element warps, distorts, or fails completely.

Why Graphite's Low CTE is a Decisive Advantage

Graphite's exceptionally low, near-zero CTE is one of its most important properties for high-temperature applications. This directly mitigates the destructive effects of thermal stress.

Unmatched Resistance to Thermal Shock

Thermal shock occurs when a material experiences a very rapid temperature change. Because graphite barely expands or contracts, it generates very little internal stress, allowing it to survive extreme thermal shocks that would shatter other materials like ceramics.

Superior Dimensional Stability

In high-precision processes like semiconductor manufacturing or crystal growth, the exact shape and position of the heating element are critical for uniform heat distribution. Graphite's low CTE ensures the element does not warp or change its geometry, maintaining process consistency and quality.

Extended Service Life and Reliability

The ultimate benefit is a longer-lasting, more predictable heating element. By minimizing the primary failure mechanism of thermal fatigue, graphite elements reduce costly downtime, maintenance, and replacement cycles, especially in applications involving thousands of thermal cycles.

Understanding the Trade-offs

While its low CTE gives graphite an incredible advantage in thermal stability, no material is perfect for every situation. The choice of heating element always involves balancing properties.

Graphite's Core Strength: Stability

Graphite's primary advantage is its structural integrity under extreme thermal cycling, especially in vacuum or inert gas environments. In these applications, its stability is unmatched.

Alternative Materials: SiC and Efficiency

Other materials, such as Silicon Carbide (SiC), are often chosen for their own unique benefits. SiC elements can offer faster heat-up times and superior performance in oxygen-rich (oxidizing) atmospheres where graphite would quickly burn away.

The Deciding Factor: Operating Environment

The trade-off is that SiC has a higher CTE than graphite, making it more susceptible to thermal shock. The decision is therefore driven by the application's specific needs: stability and vacuum performance (graphite) versus air operation and energy efficiency (SiC).

Making the Right Choice for Your Application

Selecting the correct material requires a clear understanding of your primary operational goal.

- If your primary focus is maximum reliability under rapid and repeated thermal cycles in a non-oxidizing atmosphere: Graphite's ultra-low CTE makes it the superior choice for preventing mechanical failure.

- If your primary focus is energy efficiency or operating in an open-air furnace: A material like SiC may be a better fit, even though it requires more careful management of thermal shock.

Ultimately, understanding a material's coefficient of thermal expansion empowers you to predict its behavior and design a more robust and reliable high-temperature system.

Summary Table:

| Benefit | Description |

|---|---|

| Thermal Shock Resistance | Survives rapid temperature changes without cracking. |

| Dimensional Stability | Maintains shape and geometry for uniform heating. |

| Extended Service Life | Reduces failure from thermal fatigue, lowering downtime. |

Maximize the reliability and longevity of your high-temperature processes.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Contact us today to discuss how our graphite heating elements and furnace systems can bring superior thermal stability and performance to your lab. Get in touch via our contact form for a personalized consultation.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What are the mechanical strength and durability benefits of SIC heating elements? Maximize Uptime & Reliability

- What are the common materials used for heating elements? Discover the Best Options for Your Heating Needs

- What is the temperature range where MoSi2 heating elements should not be used for long periods? Avoid 400-700°C to Prevent Failure

- How does the principle of resistance and resistivity apply to heating elements? Optimize for Efficient Heat Generation

- What applications are ceramic heating elements particularly suited for? Ideal for High-Temp, Corrosive, and Sensitive Environments

- Why is the precise spatial arrangement of thermocouple probes necessary in magnesium combustion experiments?

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- Why are MoSi2 heating elements considered versatile for industrial applications? Unlock High-Temp Reliability & Efficiency