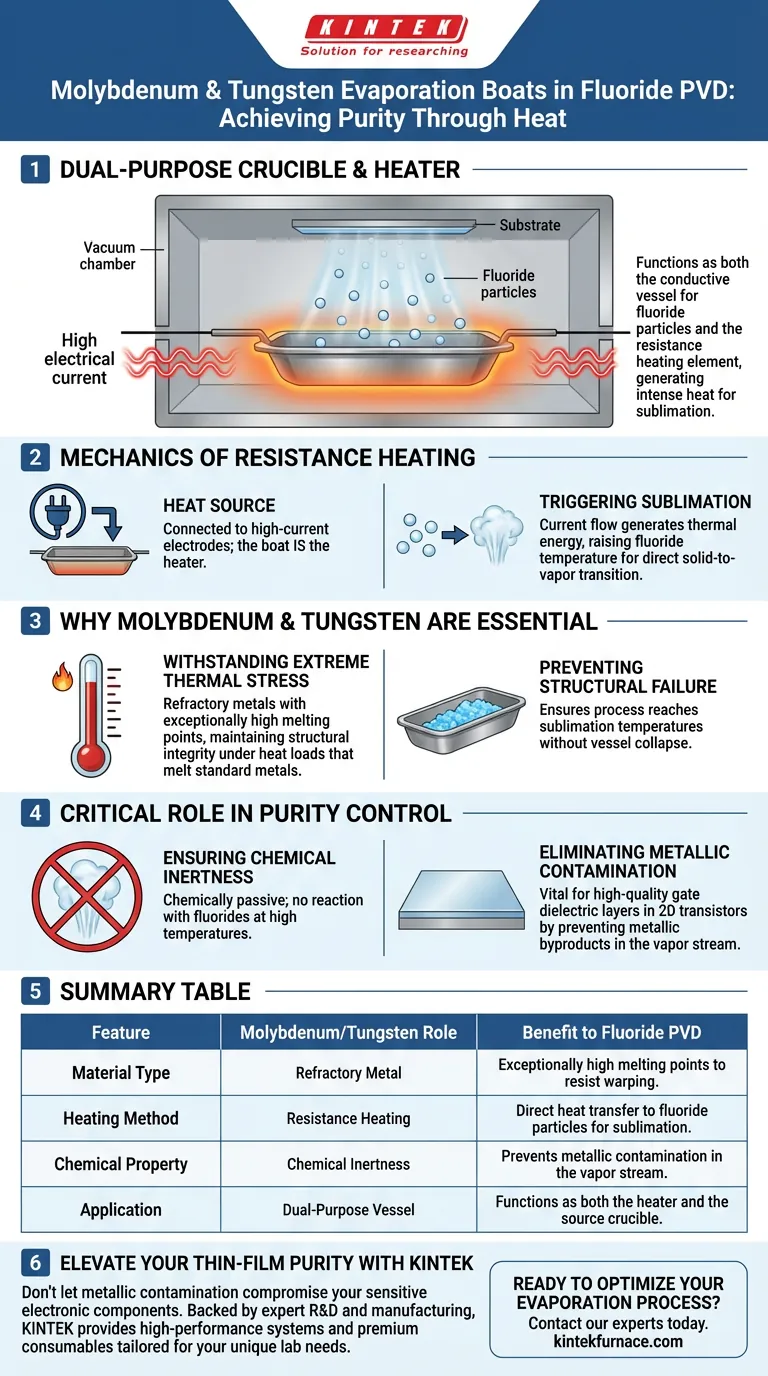

Molybdenum and tungsten evaporation boats function as dual-purpose crucibles and heating elements within the thermal evaporation physical vapor deposition (PVD) process. They serve as the conductive vessel that holds fluoride particles, allowing high electrical current to pass through the boat itself to generate the intense heat required for sublimation.

The critical value of using these refractory metals lies in their ability to withstand extreme temperatures without chemically reacting with the fluoride source, ensuring the deposited thin films retain the absolute purity necessary for sensitive electronic components.

The Mechanics of Resistance Heating

Functioning as the Heat Source

In this specific PVD setup, the boat does not merely sit on a heater; it is the heater. The molybdenum or tungsten boat is connected to high-current electrodes within a vacuum chamber.

Triggering Sublimation

As electricity flows through the metal boat, its inherent electrical resistance generates significant thermal energy. This heat is transferred directly to the fluoride particles held within the boat, raising their temperature until they sublime—transitioning directly from a solid state to a vapor phase for deposition.

Why Molybdenum and Tungsten Are Essential

Withstanding Extreme Thermal Stress

Fluorides often require high temperatures to evaporate effectively. Molybdenum and tungsten are classified as refractory metals, selected specifically for their exceptionally high melting points.

Preventing Structural Failure

These metals maintain their structural integrity under heat loads that would melt or warp standard conductive metals. This allows the process to reach the necessary sublimation point of the fluoride source material without risking the collapse of the containment vessel.

The Critical Role in Purity Control

Ensuring Chemical Inertness

The most significant role of these boats is to remain chemically passive. Molybdenum and tungsten exhibit excellent chemical inertness when in contact with fluorides at high temperatures.

Eliminating Metallic Contamination

Because the boat does not react with the source material, no metallic byproducts or impurities are introduced into the vapor stream. This isolation is vital for creating high-quality gate dielectric layers in 2D transistors, where even trace metallic contamination can ruin the device's electrical performance.

Operational Considerations

The Necessity of Material Compatibility

While these boats are robust, they are chosen specifically for their compatibility with the source material. Using a boat with lower chemical stability would result in the boat reacting with the fluoride, degrading the boat and polluting the film.

Balancing Power and Evaporation

The resistance heating process requires precise current control. The boat must be conductive enough to carry the current but resistive enough to generate the heat required to vaporize the specific fluoride compound being used.

Making the Right Choice for Your Goal

When setting up a thermal evaporation process for fluorides, your choice of boat material dictates the quality of your final film.

- If your primary focus is electronic grade purity: Select molybdenum or tungsten to ensure zero metallic contamination in sensitive layers like gate dielectrics.

- If your primary focus is process reliability: Rely on these refractory metals to maintain structural stability during repeated high-temperature sublimation cycles.

By leveraging the thermal and chemical resilience of these metals, you ensure a deposition process that is both stable and exceptionally clean.

Summary Table:

| Feature | Molybdenum/Tungsten Role | Benefit to Fluoride PVD |

|---|---|---|

| Material Type | Refractory Metal | Exceptionally high melting points to resist warping. |

| Heating Method | Resistance Heating | Direct heat transfer to fluoride particles for sublimation. |

| Chemical Property | Chemical Inertness | Prevents metallic contamination in the vapor stream. |

| Application | Dual-Purpose Vessel | Functions as both the heater and the source crucible. |

Elevate Your Thin-Film Purity with KINTEK

Don't let metallic contamination compromise your sensitive electronic components. Backed by expert R&D and manufacturing, KINTEK provides high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside premium consumables tailored for your unique lab needs. Whether you are depositing gate dielectrics or specialized coatings, our customizable high-temperature solutions deliver the precision and reliability you demand.

Ready to optimize your evaporation process? Contact our experts today to find the perfect thermal system for your research.

Visual Guide

References

- Thin Fluoride Insulators for Improved 2D Transistors: From Deposition Methods to Recent Applications. DOI: 10.1002/pssr.202500200

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the advantages of high-temperature heating elements? Boost Efficiency and Safety in Industrial Processes

- What are some applications of silicon carbide heating elements? Achieve High-Temp Precision in Labs & Industry

- What role does an industrial K-type armored thermocouple play in annealing? Real-time Embedded Process Validation

- How does a Silicon Carbide Heating Element generate heat? Discover high-temperature precision and durability

- What are the ideal applications for SiC heating elements? Boost Efficiency in High-Temp Processes

- How are Silicon Carbide Heating Elements handled during storage and transportation? Ensure Longevity and Reliability

- What are the properties and uses of Copper-Nickel (CuNi) alloy in heating elements? Ideal for Corrosive, Moderate-Temp Applications

- What are the main advantages of ceramic infrared heaters? Achieve Instant, Efficient Heating for Your Space