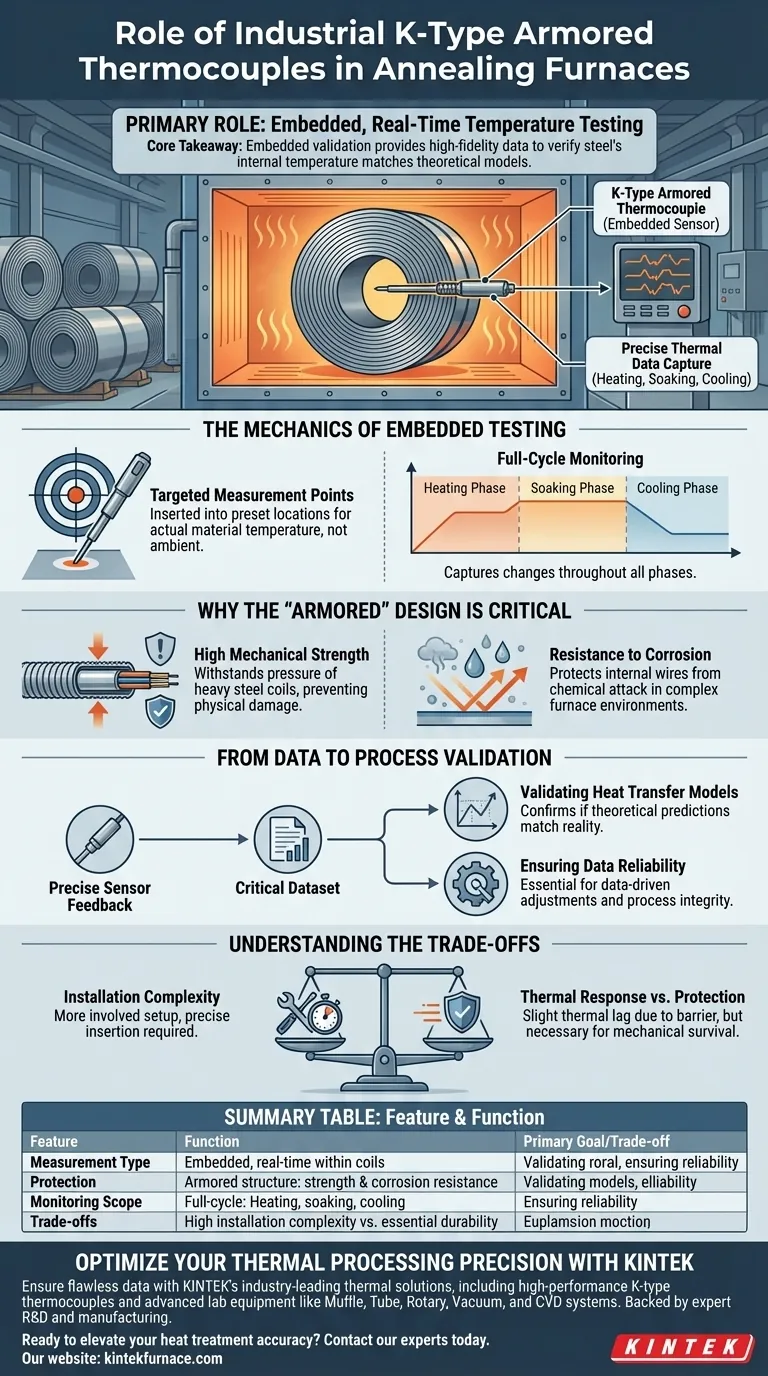

The primary role of an industrial K-type armored thermocouple in an annealing furnace is to perform embedded, real-time temperature testing. By being inserted directly into preset measurement points within steel coils, these sensors capture precise thermal data throughout the entire heating, soaking, and cooling process.

Core Takeaway While measuring furnace air temperature is common, the specific value of the K-type armored thermocouple lies in embedded validation. It provides the high-fidelity data needed to verify that the internal temperature of the steel matches the theoretical predictions of your heat transfer models.

The Mechanics of Embedded Testing

Targeted Measurement Points

To ensure accuracy, these thermocouples are not simply placed near the product; they are utilized for embedded testing.

The sensors are inserted into specific, preset locations within the steel coils. This allows operators to measure the actual material temperature rather than just the ambient environment.

Full-Cycle Monitoring

Annealing is a multi-stage process, and consistent monitoring is required across all phases.

These thermocouples capture real-time temperature changes during the heating, soaking, and cooling phases. This continuous stream of data ensures that the steel undergoes the correct thermal profile from start to finish.

Why the "Armored" Design is Critical

High Mechanical Strength

The interior of an annealing furnace is a physically demanding environment.

The armored structure of the K-type thermocouple provides the mechanical strength necessary to withstand the pressures of being embedded within heavy steel coils. This prevents physical damage to the sensor element during the loading and heating process.

Resistance to Corrosion

Furnace environments often contain complex atmospheres that can degrade standard sensors.

The armor offers vital corrosion resistance, protecting the internal wires from chemical attack. This protection ensures the feedback remains reliable and precise over the duration of the cycle.

From Data to Process Validation

Validating Heat Transfer Models

The ultimate purpose of collecting this data is often to bridge the gap between theory and reality.

The precise feedback provided by these sensors serves as the critical dataset for validating heat transfer models. It confirms whether the mathematical models used to predict furnace performance accurately reflect what is happening inside the steel.

Ensuring Data Reliability

In complex furnace environments, interference or sensor failure can lead to quality control issues.

By combining the K-type sensor's range with an armored shell, the system ensures precise and reliable temperature feedback. This reliability is essential for making data-driven adjustments to the annealing process.

Understanding the Trade-offs

Installation Complexity

Because these sensors are designed for embedded testing, the setup process is more involved than using non-contact methods.

It requires precise insertion into preset points within the coils. This increases the setup time and requires careful handling to ensure the sensor is positioned correctly for valid data collection.

Thermal Response vs. Protection

While the armored structure is essential for survival, it introduces a physical barrier between the sensor and the heat source.

This can theoretically introduce a slight thermal lag compared to exposed sensors. However, in the context of massive steel coils and long annealing cycles, this trade-off is necessary to gain the mechanical strength required for survival.

Making the Right Choice for Your Goal

To maximize the value of K-type armored thermocouples in your specific application:

- If your primary focus is Model Validation: Ensure the thermocouples are placed exactly at the preset measurement points used in your theoretical calculations to minimize data discrepancies.

- If your primary focus is Sensor Longevity: Prioritize the integrity of the armored structure to prevent corrosion and mechanical failure during the heating and soaking phases.

By leveraging the durability and precision of armored thermocouples, you transform raw temperature readings into actionable insights that guarantee process integrity.

Summary Table:

| Feature | Function in Annealing Furnace |

|---|---|

| Measurement Type | Embedded, real-time testing within steel coils |

| Protection | Armored structure provides high mechanical strength and corrosion resistance |

| Monitoring Scope | Full-cycle tracking: Heating, soaking, and cooling phases |

| Primary Goal | Validating heat transfer models and ensuring data reliability |

| Trade-offs | High installation complexity vs. essential sensor durability |

Optimize Your Thermal Processing Precision with KINTEK

Ensure your annealing cycles are backed by flawless data. KINTEK provides industry-leading thermal solutions, including high-performance K-type thermocouples and advanced laboratory equipment. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other lab high-temp furnaces—all fully customizable to meet your unique industrial needs.

Ready to elevate your heat treatment accuracy? Contact our experts today to discuss your custom furnace and sensing requirements.

Visual Guide

References

- Yang Xiao-jing, Yu-Ren Li. Study of heat transfer model and buried thermocouple test of bell-type annealing furnace based on thermal equilibrium. DOI: 10.1038/s41598-025-97422-4

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How high-precision thermocouples monitor PTC-TEG-MOF systems? Enhance Thermal Gradient & Energy Harvesting Analysis

- What precautions should be taken when handling MoSi2 heating elements? Ensure Longevity and Safety in High-Temp Applications

- What are the electrical properties of molybdenum? A Guide to High-Temp Conductor Performance

- How convenient are MoSi2 heating elements to install and maintain? Maximize Uptime with Easy Hot-Swappable Elements

- Why is a multi-stage thermocouple measurement system necessary? Validate Composite Fuel Combustion Performance

- What is the role of electrical resistance in a heating element? The Key to Controlled Heat Generation

- What are the two types of silicon carbide heating elements described? Compare One-Piece vs. Three-Piece for Your Lab

- What type of heating elements are commonly used in both tube and box furnaces? Explore Key Choices for High-Temp Labs