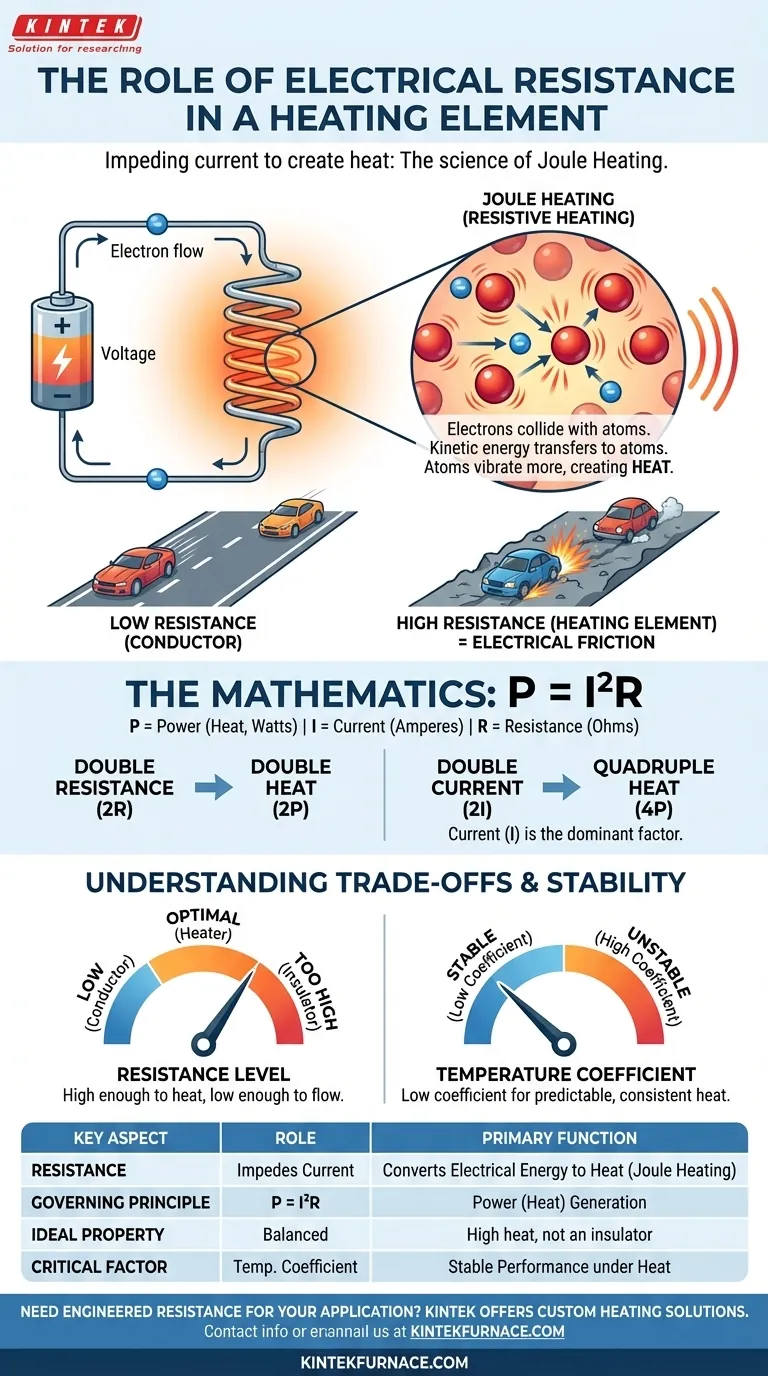

In a heating element, electrical resistance is the fundamental property that makes it work. Its primary role is to deliberately impede the flow of electric current, forcing the conversion of electrical energy directly into thermal energy. This process, known as Joule heating, happens when electrons collide with the atoms of the resistive material, transferring their energy and causing the material to heat up.

The core function of resistance in a heating element is to act as a controlled bottleneck for electricity. It must be high enough to generate substantial heat, yet low enough to permit a sufficient current to flow through it.

The Principle: How Resistance Creates Heat

At a microscopic level, the conversion of electricity to heat is a simple process of energy transfer. Understanding this mechanism is key to understanding why certain materials are chosen for heating elements.

The Phenomenon of Joule Heating

Joule heating, also called resistive heating, is the physical principle at play. When a voltage is applied, it pushes electrons through the heating element's material.

The Role of Atomic Collisions

A material with high resistance has an atomic structure that makes it difficult for electrons to pass through smoothly. As electrons are forced through, they constantly collide with the atoms of the element.

Each collision transfers kinetic energy from the electron to the atom, causing the atom to vibrate more intensely. This increased atomic vibration is what we perceive and measure as heat.

An Analogy: Electrical Friction

Think of a low-resistance copper wire as a wide, smooth highway where electrons (cars) can travel with minimal obstruction. A high-resistance heating element, in contrast, is like a narrow, rough road. The constant friction and bumping on this road slows the cars down and generates significant heat.

The Mathematics of Heat Generation

The relationship between resistance, current, and heat output is defined by a clear mathematical formula. This equation reveals that resistance is just one part of the story.

The Power Formula: P = I²R

The amount of power (heat) generated is calculated with the formula P = I²R.

- P is Power, measured in Watts, which is dissipated as heat.

- I is Current, the flow of electrons, measured in Amperes.

- R is Resistance, measured in Ohms.

Why Current is the Dominant Factor

This formula immediately highlights a critical point: power is proportional to the resistance (R), but it is proportional to the square of the current (I²).

This means doubling the resistance will double the heat output. However, doubling the current will quadruple the heat output. This makes managing current a highly effective way to control temperature.

Understanding the Trade-offs

Selecting the right resistance is a balancing act. Too high or too low presents significant problems, and the material's behavior under heat is just as important as its base resistance.

The Line Between Resistor and Insulator

While high resistance is necessary, if it's too high, the material becomes an insulator. An insulator stops the flow of current almost completely. Since no current can flow (or very little), no heat will be generated according to the P = I²R formula.

The Importance of Temperature Stability

A material's resistance can change as its temperature changes. This property is called the temperature coefficient of resistance. For most applications, a low coefficient is ideal, as it means the resistance remains stable and the heat output is predictable and consistent as the element heats up.

When Instability Can Be Useful

In some advanced designs, a material with a high temperature coefficient is used intentionally. As the element heats up, its resistance rapidly increases. If this change is predictable, it can be used to quickly ramp up power delivery or act as a self-regulating feature.

Making the Right Choice for Your Goal

The ideal resistance characteristics depend entirely on the specific application and desired performance.

- If your primary focus is efficient heat generation: Prioritize a material with high electrical resistance to maximize the conversion of electrical energy into heat.

- If your primary focus is stable and predictable performance: Select a material with a low temperature coefficient, ensuring its resistance doesn't change drastically as it heats up.

- If your primary focus is overall system design: Remember that heat is proportional to the square of the current (P = I²R), so managing current is often more impactful than simply maximizing resistance.

Ultimately, a well-designed heating element is a perfect example of controlled inefficiency, engineered to resist the flow of electricity just enough to create the precise amount of heat required.

Summary Table:

| Key Aspect | Role in Heating Element |

|---|---|

| Primary Function | Impedes current flow to convert electrical energy into heat (Joule heating). |

| Governing Principle | Power (Heat) generated is calculated by P = I²R. |

| Ideal Property | High enough to generate substantial heat, but not so high it acts as an insulator. |

| Critical Factor | Temperature coefficient of resistance for stable performance under heat. |

Need a heating element with precisely engineered resistance for your application?

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD furnace systems, all featuring custom heating elements designed for optimal performance and durability. Our elements are tailored to provide the exact resistance characteristics your process requires, ensuring efficient, stable, and predictable heat generation.

Contact us today to discuss how our high-temperature laboratory furnaces and custom heating solutions can enhance your efficiency and results.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability