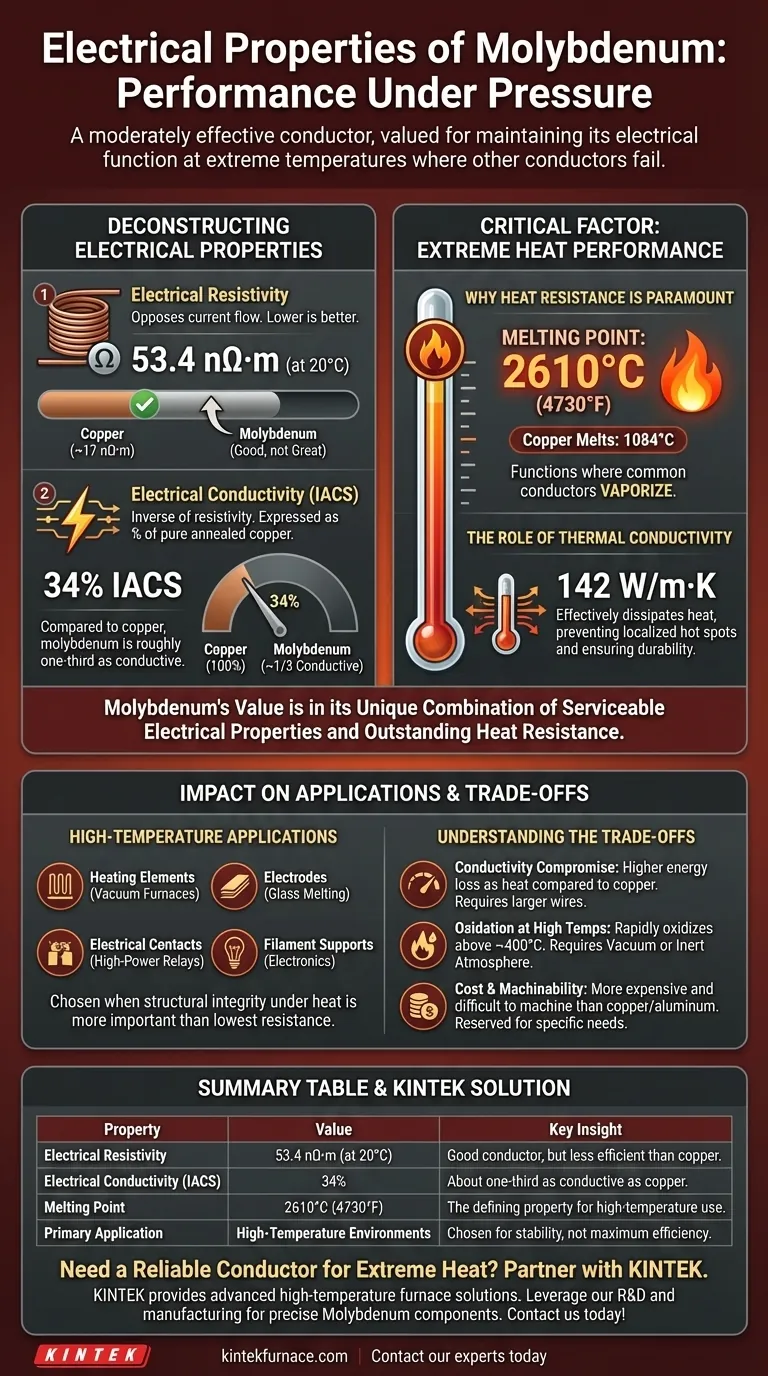

In essence, molybdenum is a moderately effective electrical conductor, notable not for its efficiency but for its ability to maintain that conductivity at extremely high temperatures where common conductors would fail. Its electrical resistivity is 53.4 nΩ·m at 20°C, and its electrical conductivity is rated at 34% IACS, meaning it is about one-third as conductive as annealed copper.

Molybdenum's value is not in being the best conductor, but in its unique combination of serviceable electrical properties and outstanding resistance to heat. It is a specialist material chosen when an application is too hot for conventional conductors like copper or aluminum.

Deconstructing the Electrical Properties

To properly evaluate molybdenum, we must look at its two key electrical metrics and understand what they mean in a practical context.

Electrical Resistivity

Electrical resistivity measures how strongly a material opposes the flow of electric current. A lower value is better for conducting electricity.

Molybdenum's resistivity of 53.4 nΩ·m places it in the category of a "good" conductor, but not a "great" one. For comparison, copper's resistivity is around 17 nΩ·m, making it a far more efficient conductor at room temperature.

Electrical Conductivity

Conductivity is the inverse of resistivity. It is often expressed as a percentage of the International Annealed Copper Standard (IACS), where pure annealed copper is set as the 100% benchmark.

Molybdenum’s rating of 34% IACS provides a direct and clear comparison: it is approximately one-third as conductive as copper. This means that for a wire of the same dimensions, a molybdenum wire will have roughly three times the electrical resistance of a copper one.

The Critical Factor: Performance Under Extreme Heat

The raw electrical numbers only tell part of the story. Molybdenum's true purpose in electrical systems is revealed when its exceptional thermal properties are considered.

Why Heat Resistance is Paramount

Molybdenum has an extremely high melting point of 2610°C (4730°F). This is its defining characteristic.

While copper is a superior conductor, it melts at 1084°C. Molybdenum can continue to function as an electrical component at temperatures that would instantly vaporize more common conductors.

The Impact on Applications

This heat resistance makes molybdenum indispensable for high-temperature electrical applications. These include:

- Heating elements in vacuum furnaces

- Electrodes for glass melting

- Electrical contacts in high-power relays

- Filament supports in lighting and electronics

In these environments, the ability to simply survive and maintain structural integrity is far more important than achieving the lowest possible electrical resistance.

The Role of Thermal Conductivity

Molybdenum also possesses good thermal conductivity of 142 W/m·K. This is a crucial secondary benefit.

It allows the material to effectively dissipate heat generated by electrical resistance, preventing the formation of localized hot spots that could lead to mechanical failure. This ability to manage its own heat contributes to its overall durability in extreme service.

Understanding the Trade-offs

Choosing molybdenum involves a clear set of compromises. It is a solution for a specific problem, not a general-purpose conductor.

The Conductivity Compromise

The primary trade-off is efficiency. Using molybdenum where copper could suffice would result in higher energy loss (as heat), requiring larger wires to carry the same current and increasing operational costs. It is not an appropriate substitute for copper or aluminum in standard wiring applications.

Oxidation at High Temperatures

While molybdenum withstands heat, it does not withstand oxygen at high temperatures. Above approximately 400°C, it begins to oxidize rapidly. Therefore, it must be used in a vacuum or a protective, inert atmosphere (like argon or nitrogen) to prevent this degradation.

Cost and Machinability

As a refractory metal, molybdenum is significantly more expensive and difficult to machine and form than common materials like copper or aluminum. This high cost reserves its use for applications where its unique properties are not just beneficial, but absolutely required.

Making the Right Choice for Your Application

Your decision to use molybdenum should be based entirely on the operating environment of the electrical component.

- If your primary focus is stability at extreme temperatures: Molybdenum is an excellent choice for components like furnace windings, electrodes, or high-temperature sensor leads.

- If your primary focus is maximum electrical efficiency: Copper or aluminum are the correct, more cost-effective choices for standard wiring and components operating near ambient temperatures.

Ultimately, you select molybdenum not for its electrical properties alone, but for the resilience of those properties under thermal duress.

Summary Table:

| Property | Value | Key Insight |

|---|---|---|

| Electrical Resistivity | 53.4 nΩ·m (at 20°C) | Good conductor, but not as efficient as copper. |

| Electrical Conductivity (IACS) | 34% | About one-third as conductive as copper. |

| Melting Point | 2610°C (4730°F) | The defining property for high-temperature use. |

| Primary Application | High-Temperature Environments | Chosen for stability, not maximum efficiency. |

Need a Reliable Conductor for Extreme Heat? Partner with KINTEK.

Molybdenum's unique ability to maintain electrical function at extreme temperatures makes it indispensable for demanding applications like furnace heating elements, glass melting electrodes, and high-power electrical contacts. However, leveraging this material effectively requires precise engineering and manufacturing.

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, and Vacuum & Atmosphere Furnaces, is complemented by our strong deep customization capability to precisely meet your unique experimental or industrial requirements.

Let us help you build a more robust and efficient high-temperature system. Contact our experts today to discuss your specific needs.

Visual Guide

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What ceramic materials are commonly used for heating elements? Discover the Best for Your High-Temp Needs

- What are the primary applications of Molybdenum Disilicide (MoSi2) heating elements in furnaces? Achieve High-Temp Excellence

- What are the advantages of using molybdenum-disilicide heating elements for aluminum alloy processing? (Rapid Heating Guide)

- What types of molybdenum disilicide heating elements are available? Choose the Right Element for Your High-Temp Needs

- What is the temperature range where MoSi2 heating elements should not be used for long periods? Avoid 400-700°C to Prevent Failure