In heating element design, Copper-Nickel (CuNi) alloy is specifically chosen for its unique combination of moderate-temperature performance, useful electrical resistivity, and exceptional corrosion resistance. Its key properties include an electrical resistivity of 50 μΩ-cm, a melting point of 1,280°C, and superior durability in humid or marine environments, making it a reliable material for specialized applications.

The core challenge in selecting a heating element material is balancing performance, lifespan, and cost. Copper-Nickel is the definitive solution when corrosion is the primary point of failure, but operating temperatures remain moderate.

The Fundamental Properties of CuNi

To understand where CuNi fits, you must first understand its core characteristics. These properties dictate its ideal use cases and its limitations.

Electrical Resistivity

The electrical resistivity of CuNi is approximately 50 μΩ-cm at room temperature. This level of resistance is high enough to generate heat efficiently through the Joule effect (P=I²R) without requiring excessive length or thinness in the wire.

This makes it a more effective resistance material than pure copper, which is designed for low-resistance conductivity.

Operating Temperature Range

CuNi has a high melting point of 1,280°C, but it is not intended for use at such extreme temperatures. It is best suited for moderate-temperature applications, typically operating well below 600°C (1112°F).

Above this range, its mechanical properties and oxidation resistance begin to decline, making high-temperature alloys like Nichrome a better choice.

Corrosion Resistance: The Defining Feature

This is CuNi's most important property. The addition of nickel to copper creates an alloy that is highly resistant to corrosion from moisture, saltwater, and various chemicals.

This makes it exceptionally durable in environments where pure copper or iron-based alloys would quickly degrade and fail.

Where CuNi Excels: Key Applications

The unique properties of CuNi make it the material of choice for heating elements that must perform reliably in challenging, corrosive conditions.

Marine and Humid Environments

CuNi is the standard for marine applications, including onboard water heaters and de-icing equipment. Its ability to withstand constant exposure to salt spray and high humidity ensures a long and reliable service life.

Food Processing and Medical Systems

In food processing and medical sterilization equipment, preventing contamination is critical. CuNi's corrosion resistance ensures that the heating element itself does not become a source of impurities.

This stability makes it ideal for direct or indirect heating of liquids and for systems requiring frequent cleaning with chemical agents.

Understanding the Trade-offs: CuNi vs. Other Alloys

No single material is perfect for all applications. Choosing CuNi is a deliberate engineering decision based on a clear understanding of its position relative to other common alloys.

CuNi vs. Pure Copper

Pure copper is an excellent thermal and electrical conductor but corrodes easily, especially at elevated temperatures.

You choose CuNi over copper when your application involves any moisture or corrosive agents that would compromise the element's integrity. CuNi sacrifices some of copper's conductivity for vastly superior durability.

CuNi vs. High-Temperature Alloys (Ni-Cr)

Alloys like Nickel-Chromium (Nichrome) and Fe-Cr-Al are designed specifically for high-temperature environments, such as industrial furnaces and home appliances like toasters and ovens.

These alloys can operate reliably above 600°C, a threshold where CuNi is not recommended. If your application requires high heat, CuNi is the wrong choice.

CuNi vs. Premium Options (Platinum)

Platinum offers outstanding performance, with a very high melting point (1768°C) and near-total immunity to corrosion. However, its extremely high cost restricts its use to specialized laboratory equipment and sensors.

CuNi provides a pragmatic and cost-effective alternative, delivering excellent corrosion resistance for a fraction of the price of platinum.

Making the Right Choice for Your Application

Selecting the correct alloy requires you to prioritize your design goals. Your decision should be based on the specific demands of the operating environment and target temperature.

- If your primary focus is corrosion resistance in moderate heat: CuNi is the ideal choice, offering durability where other materials would fail.

- If your primary focus is reaching very high temperatures (above 600°C): You must use a specialized resistance alloy like Nichrome (Ni-Cr) or Fe-Cr-Al.

- If your primary focus is lowest cost for low-temperature, dry environments: Pure copper may be sufficient if corrosion is not a significant concern.

- If your primary focus is maximum performance regardless of cost: Platinum offers the ultimate in temperature stability and corrosion resistance for highly specialized equipment.

By understanding these material trade-offs, you can select the precise alloy that delivers the required performance and longevity for your specific heating application.

Summary Table:

| Property | Value/Description |

|---|---|

| Electrical Resistivity | 50 μΩ-cm |

| Melting Point | 1,280°C |

| Operating Temperature | Up to 600°C |

| Key Advantage | Superior corrosion resistance |

| Common Applications | Marine heaters, food processing, medical sterilization |

Need a custom heating solution for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet unique experimental requirements in corrosive or moderate-temperature environments. Contact us today to enhance your lab's efficiency and durability!

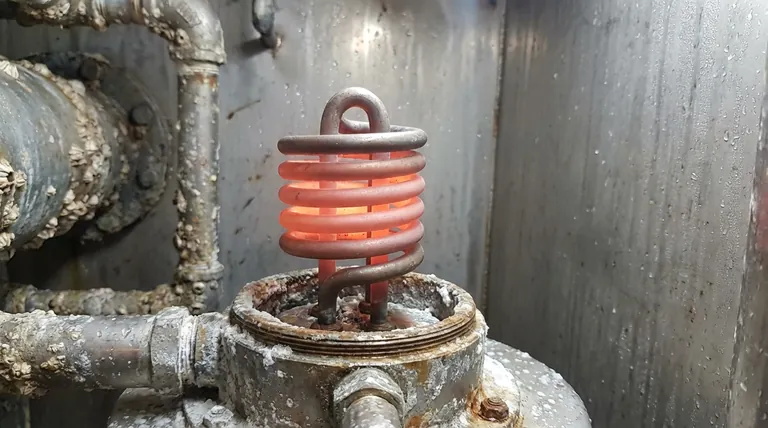

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency