In short, modern ceramic infrared heaters are designed with several critical safety features. These typically include internal sensors that shut the unit off in case of overheating or tipping over, alongside user-controlled features like timers and thermostats for managed operation.

While no heating device is entirely without risk, ceramic infrared heaters are engineered to mitigate the most common hazards through automated sensors and controls. Your primary task is to understand what these features are and ensure the model you choose has them.

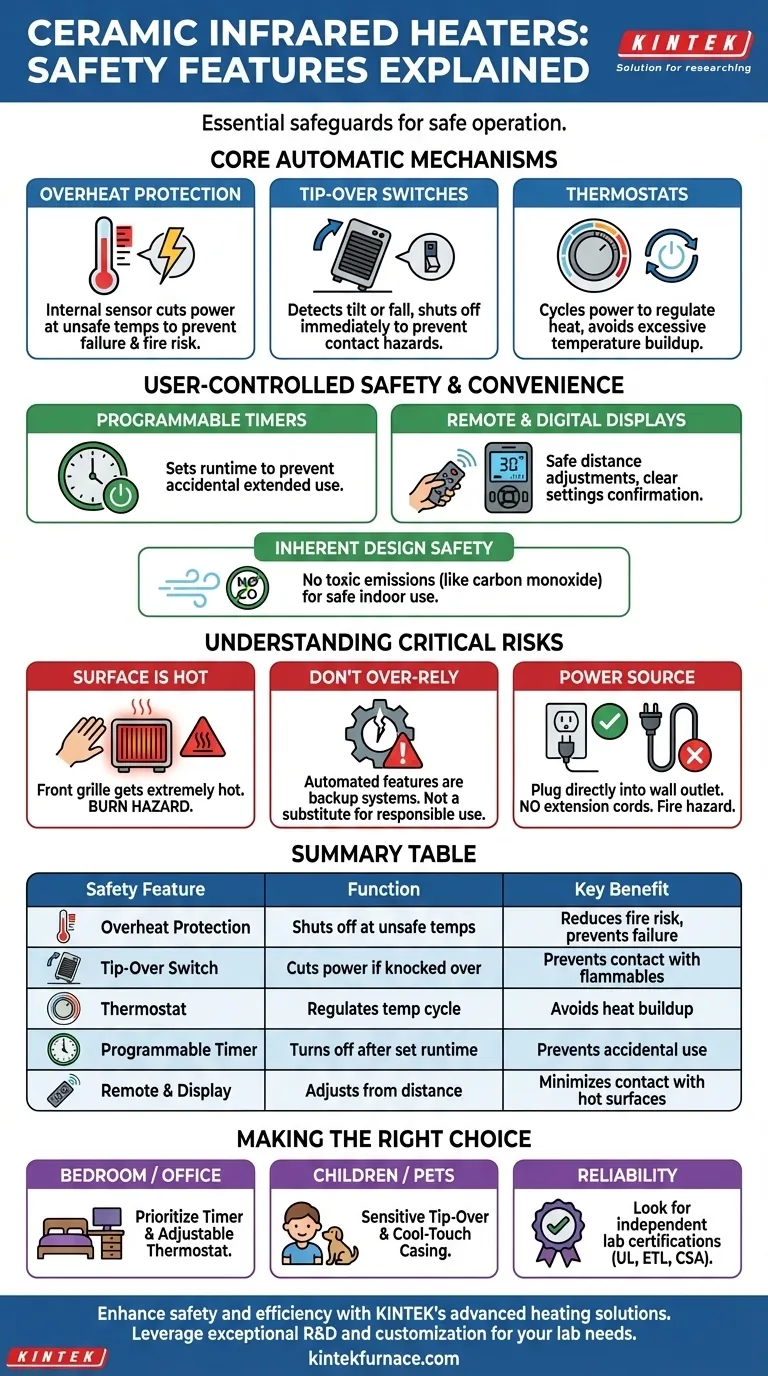

The Core Safety Mechanisms Explained

Ceramic heaters use a resistive heating element encased in ceramic plates. This design allows them to generate significant, efficient heat, which makes built-in safety mechanisms non-negotiable.

Overheat Protection: The First Line of Defense

Most reputable ceramic infrared heaters contain an internal thermal sensor.

If the internal components reach an unsafe temperature, this sensor automatically cuts power to the heating element, preventing component failure and drastically reducing fire risk.

Tip-Over Switches: Preventing Contact Hazards

A tip-over switch is another essential automatic shutoff feature.

It's a simple sensor (often a physical switch or accelerometer) that detects if the heater is tilted or knocked over. It immediately cuts power, preventing the hot surface from making direct contact with flammable materials like carpets, bedding, or curtains.

Thermostats: Regulating Heat and Power

A thermostat is more than a convenience; it's a primary safety control.

By setting a target temperature, you ensure the heater cycles on and off rather than running continuously. This prevents the unit and the surrounding space from reaching excessive temperatures.

User-Controlled Safety and Convenience

Beyond the automatic shutoffs, other features give you direct control over the heater's safe operation.

Programmable Timers

A timer allows you to set a specific runtime, after which the heater will turn off automatically. This is a crucial feature to prevent a heater from being left on accidentally for an extended period or overnight.

Remote Controls and Digital Displays

While they seem like pure convenience, remote controls and clear displays contribute to safety.

They allow you to adjust settings or turn the unit off from a distance, removing any need to touch the device when it is hot. A clear display confirms the heater's current settings at a glance.

Inherent Design Safety

The "no toxic emissions" advantage is a key safety point. Unlike fuel-burning heaters, these electric units do not produce carbon monoxide or other dangerous fumes, making them safe for indoor use.

Understanding the Trade-offs and Risks

Even the best safety features do not eliminate all risk. Objective awareness is key to safe operation.

Surface Temperature is Still a Hazard

The front grille and heating elements of a ceramic infrared heater get extremely hot during operation. They can cause serious burns on contact, making placement a critical concern, especially in homes with children or pets.

Over-reliance on Automated Features

Safety features can fail. Never assume a tip-over switch or overheat sensor is a substitute for responsible use. These are backup systems, not a license to be careless.

Placement and Power Source

Never use an extension cord or power strip for a space heater. These devices draw a significant amount of current that can overload most cords, creating a severe fire hazard. Always plug them directly into a suitable wall outlet.

Making the Right Choice for Your Goal

When selecting a heater, match its safety features to your specific use case.

- If your primary focus is use in a bedroom or office: Prioritize a model with both a programmable timer and a highly-rated, adjustable thermostat to ensure it shuts off as intended.

- If your primary focus is safety around children or pets: A unit with a sensitive tip-over switch and a "cool-touch" exterior casing is essential to prevent both fire and burn risks.

- If your primary focus is all-around reliability: Look for a safety certification mark from an independent testing lab (like UL, ETL, or CSA) on the product, which verifies its safety claims.

By understanding these built-in safeguards, you can confidently select a heater that provides warmth without compromising safety.

Summary Table:

| Safety Feature | Function | Key Benefit |

|---|---|---|

| Overheat Protection | Automatically shuts off at unsafe temperatures | Reduces fire risk and prevents component failure |

| Tip-Over Switch | Cuts power if heater is knocked over | Prevents contact with flammable materials |

| Thermostat | Regulates temperature to cycle on/off | Avoids excessive heat buildup |

| Programmable Timer | Turns off after set runtime | Prevents accidental extended use |

| Remote Control & Display | Allows adjustments from a distance | Minimizes contact with hot surfaces |

Ensure your laboratory or workspace stays safe and efficient with KINTEK's advanced heating solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability allows us to precisely meet your unique experimental needs. Contact us today to discuss how our products can enhance your safety and performance!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment