The primary advantage of a chemical vapor deposition (CVD) tube equipped with a pressure regulator is its ability to create a stable, isolated reaction environment without the cost or complexity of ultra-high vacuum systems. By isolating the internal chamber from the external atmosphere, the regulator allows for precise control over internal pressure even as temperatures rise.

Core Insight: High-quality crystal growth relies on chemical equilibrium. A pressure-regulated system traps volatile byproducts that would otherwise escape, forcing reverse reactions that maintain the correct stoichiometry of sensitive materials like perovskites.

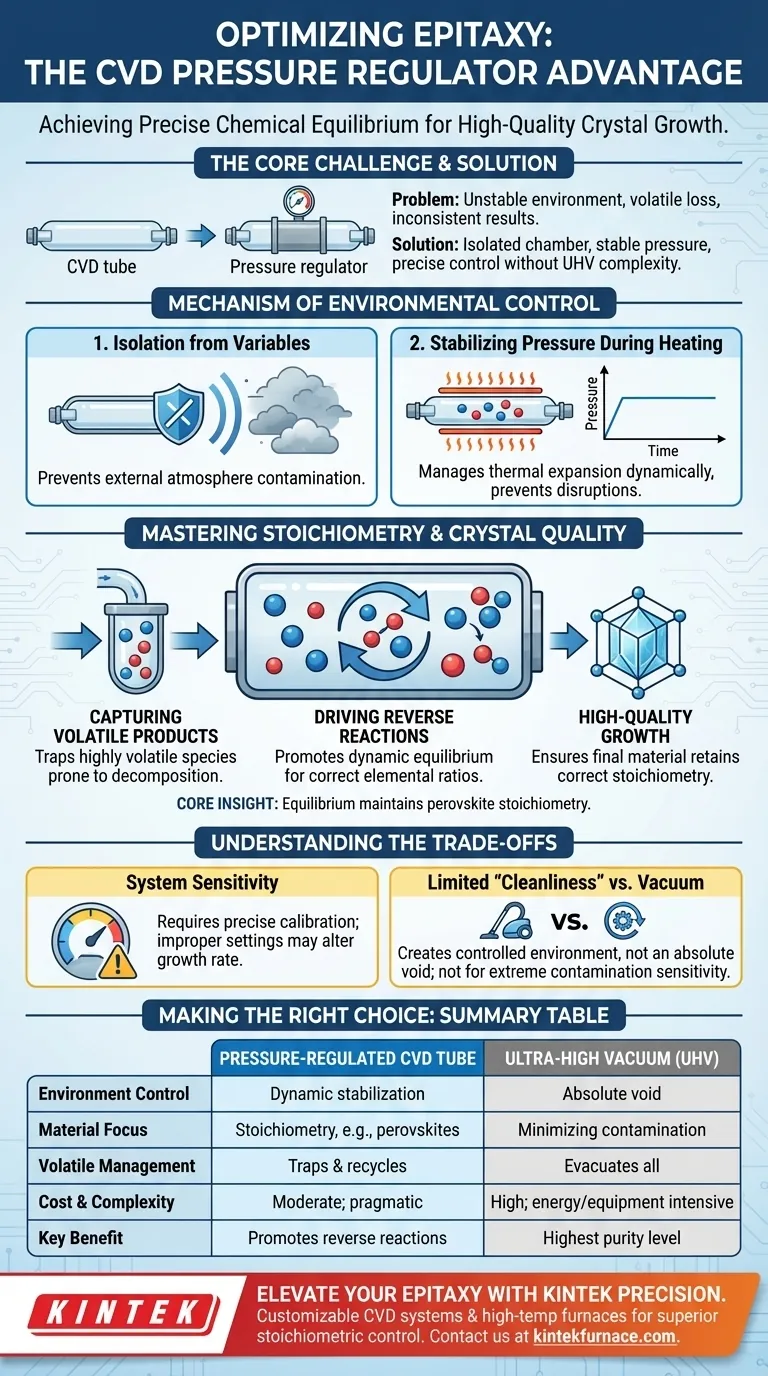

The Mechanism of Environmental Control

Isolation from External Variables

The pressure regulator acts as a barrier between the reaction and the outside world. It ensures that the external atmosphere does not contaminate the delicate chemical processes occurring inside the tube.

Stabilizing Pressure During Heating

As the CVD tube heats up, gases inside naturally expand. The regulator manages this thermal expansion dynamically. It maintains a stable internal pressure profile throughout the temperature ramp, preventing fluctuations that could disrupt crystal formation.

Controlling Stoichiometry and Crystal Quality

Capturing Volatile Products

In contact transfer epitaxy, certain reaction byproducts or precursors are highly volatile and prone to decomposing. In an open system, these components would simply evaporate and be lost. The regulated environment traps these volatile species within the reaction zone.

Driving Reverse Reactions

Because these volatile components are captured rather than lost, they remain available to participate in the reaction chemistry. This availability promotes necessary reverse reactions. This dynamic equilibrium is critical for ensuring the final material retains the correct elemental ratios (stoichiometry).

Efficiency Without Ultra-High Vacuum

This setup offers a pragmatic balance for high-quality growth. It achieves the environmental control necessary for complex crystals without requiring the immense energy and equipment footprint of ultra-high vacuum conditions.

Understanding the Trade-offs

System Sensitivity

While effective, adding a pressure regulator introduces a variable that must be monitored. If the regulator is improperly calibrated, it may either vent too much precursor material or fail to release enough pressure, potentially altering the growth rate.

Limited "Cleanliness" Compared to Vacuum

This method creates a controlled environment, not a void. While it prevents external contamination, it does not evacuate background gases as thoroughly as an ultra-high vacuum system, which may be a limitation for extremely contamination-sensitive applications outside of standard perovskites.

Making the Right Choice for Your Goal

To determine if this setup is right for your specific synthesis, consider your material constraints:

- If your primary focus is stoichiometric precision: Use a pressure-regulated CVD tube to ensure volatile components are retained and chemical equilibrium is maintained.

- If your primary focus is absolute minimum contamination: You may still require an ultra-high vacuum system if your material cannot tolerate even trace background gases.

By managing pressure to control chemical volatility, you transform the reaction environment from a passive vessel into an active participant in crystal growth.

Summary Table:

| Feature | Pressure-Regulated CVD Tube | Ultra-High Vacuum (UHV) |

|---|---|---|

| Environment Control | Dynamic pressure stabilization | Absolute void/minimum gases |

| Material Focus | Maintaining stoichiometry (e.g., perovskites) | Minimizing total contamination |

| Volatile Management | Traps and recycles volatile byproducts | Evacuates all species |

| Cost & Complexity | Moderate; pragmatic for high-quality growth | High; energy and equipment intensive |

| Key Benefit | Promotes necessary reverse reactions | Highest possible purity level |

Elevate Your Epitaxy with KINTEK Precision

Ready to achieve superior stoichiometric control in your thin-film research? KINTEK provides industry-leading, customizable CVD systems and lab high-temp furnaces designed to meet the rigorous demands of modern material science.

Backed by expert R&D and manufacturing, our systems—including Tube, Muffle, Rotary, and Vacuum furnaces—are engineered to help you maintain the perfect chemical equilibrium for high-quality crystal growth.

Don't settle for inconsistent results. Contact our technical specialists today to find the ideal regulated CVD solution for your unique laboratory needs.

Visual Guide

References

- Hongyu Sun, Erik C. Garnett. Contact Transfer Epitaxy of Halide Perovskites. DOI: 10.1002/adma.202308892

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are CVD materials? A Guide to High-Performance Thin Films and Coatings

- What types of diamond and carbon nanofilms can be prepared using CVD? Explore the Full Spectrum from Diamond to Graphene

- What are the environmental concerns related to CVD? Managing Risks in Thin Film Coating

- What are the benefits of using a CVD furnace? Achieve Atomic-Level Control for Superior Thin Films

- What are the advantages of using a CVD tube furnace for preparing gate dielectrics? Achieve High-Quality Thin Films for Transistors

- What is the role of an open-flow cold-wall CVD system in HfO2 preparation? Achieve High Purity & Uniformity

- What factors contribute to variation in the CVD coating process? Master Consistency in Chemical Vapor Deposition

- What is a Chemical Vapor Deposition (CVD) furnace used for? Precision Thin Films for Electronics & Materials