The integrity of the quartz boat is a fundamental variable in the successful synthesis of Silicon-Boron (Si:B) nanowires. These carriers must function as chemically inert vessels capable of withstanding the high-temperature zone of a tubular furnace without introducing contaminants or triggering secondary reactions that would compromise the material's purity.

The quartz boat acts as more than a simple container; it defines the chemical baseline of the reaction environment. Its heat resistance and chemical stability prevent unwanted interactions with precursors, while rigorous cleaning is the only way to ensure the high purity required for accurate photoelectric performance evaluations.

The Critical Role of Material Properties

To produce high-quality nanowires, the carrier material must be as robust as the synthesis process itself. The physical properties of quartz are selected to withstand specific environmental stressors.

Withstanding Thermal Extremes

Quartz boats serve as the direct carrier for precursor powders. They are positioned within the high-temperature zone of a tubular furnace.

Consequently, the material must exhibit exceptional heat resistance. It must maintain structural integrity and not deform or degrade when exposed to the intense thermal energy required for synthesis.

Preventing Chemical Interference

Beyond heat, chemical stability is paramount. At elevated temperatures, many materials become reactive.

The quartz used must be inert to prevent secondary reactions with the reactants. If the boat reacts with the precursor powders, it alters the chemical composition of the environment, leading to failed synthesis or impure results.

The Imperative of Rigorous Cleanliness

Even the highest quality quartz is ineffective if its surface is compromised. Surface contaminants are a leading cause of defects in nanowire production.

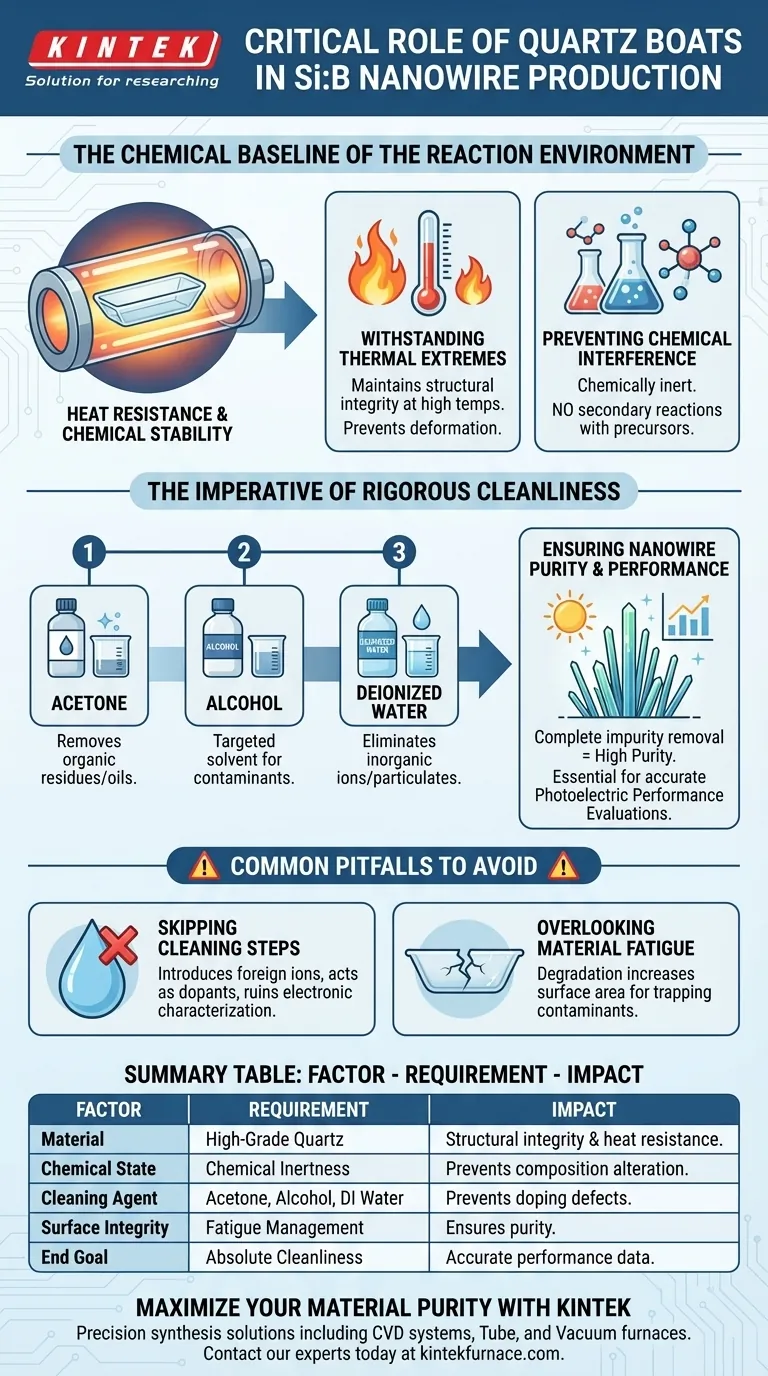

The Multi-Stage Cleaning Protocol

Standard cleaning methods are insufficient for this level of synthesis. A rigorous, multi-step process is essential to prepare the surface.

The protocol involves washing with acetone, alcohol, and deionized water. This specific combination of solvents targets different types of residues, from organic oils to inorganic particulates.

Ensuring Nanowire Purity

The primary goal of this cleaning regime is the complete removal of surface impurities.

Any residue left on the boat can vaporize or migrate during heating, becoming incorporated into the growing Si:B nanowires. This compromises the high purity necessary for semiconductor applications.

Protecting Photoelectric Performance

Purity is directly linked to function. Impurities introduced by a dirty boat can alter the electronic properties of the nanowires.

By ensuring a pristine carrier surface, you prevent interference with subsequent photoelectric performance evaluations. A clean boat ensures that the data you collect reflects the true properties of the nanowire, not the contaminants.

Common Pitfalls to Avoid

Neglecting the "passive" components of your experimental setup is a frequent source of error. Understanding the risks ensures consistent reproducibility.

The Risk of "Good Enough" Cleaning

Skipping steps in the acetone-alcohol-water cycle is a critical error. Traces of tap water or insufficient solvent drying can introduce foreign ions that act as dopants or defects, ruining the electronic characterization of the batch.

Overlooking Material Fatigue

While chemically stable, quartz can degrade over repeated high-temperature cycles. Using a fatigued or etched boat increases the surface area for trapping contaminants, making the rigorous cleaning process less effective over time.

Making the Right Choice for Your Goal

Selecting and maintaining your quartz boats is not an administrative task; it is a chemical necessity.

- If your primary focus is High Purity Synthesis: Adhere strictly to the three-step cleaning process (acetone, alcohol, deionized water) before every single run to eliminate surface contaminants.

- If your primary focus is Accurate Characterization: Ensure your boat material offers maximum chemical stability to prevent secondary reactions that would skew photoelectric performance data.

Treat the quartz boat as a reactive variable in your experiment, and you will secure the baseline purity required for high-performance Si:B nanowires.

Summary Table:

| Factor | Requirement | Impact on Si:B Nanowire Quality |

|---|---|---|

| Material | High-Grade Quartz | Ensures structural integrity and heat resistance in high-temp zones. |

| Chemical State | Chemical Inertness | Prevents secondary reactions that alter nanowire composition. |

| Cleaning Agent | Acetone, Alcohol, DI Water | Removes organic oils and inorganic ions to prevent doping defects. |

| Surface Integrity | Fatigue Management | Maintains smooth surfaces to prevent contaminant trapping and ensure purity. |

| End Goal | Absolute Cleanliness | Secures accurate photoelectric performance evaluation and reliability. |

Maximize Your Material Purity with KINTEK

Precision synthesis starts with the right environment. KINTEK provides high-performance lab solutions, including customizable CVD systems, Tube, and Vacuum furnaces designed to meet the rigorous thermal and chemical demands of nanowire production. Backed by expert R&D and manufacturing, we empower researchers to achieve superior results with equipment tailored to your unique specifications.

Ready to elevate your lab's performance? Contact our experts today to find the perfect high-temperature furnace solution for your research.

Visual Guide

References

- Feng Yang, Shihua Zhao. Preparation and photoelectric properties of Si:B nanowires with thermal evaporation method. DOI: 10.1371/journal.pone.0316576

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Magnesium Extraction and Purification Condensing Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What technical considerations justify the use of high-purity alumina crucibles for microwave-assisted metal reduction?

- How does insulation affect laboratory furnace design? Optimize Thermal Performance and Safety

- What is the point of a vacuum chamber? Achieve Absolute Control in Your Processes

- Why is a silica crucible selected as the reaction vessel? Ensure Stability and Purity in High-Temp Synthesis

- What are the advantages of using a quartz glass reactor? Superior Visibility & Purity in Molten Salt Experiments

- What are the functions of silicon nitride ceramic sample holders? Precision for High-Temperature Levitation

- What is the role of a quartz reactor within a vacuum distillation apparatus for metal recovery? Unlocking Efficient High-Purity Extraction

- How does an automatic temperature control system affect bio-char? Engineer Precise Energy Density & Pore Structure