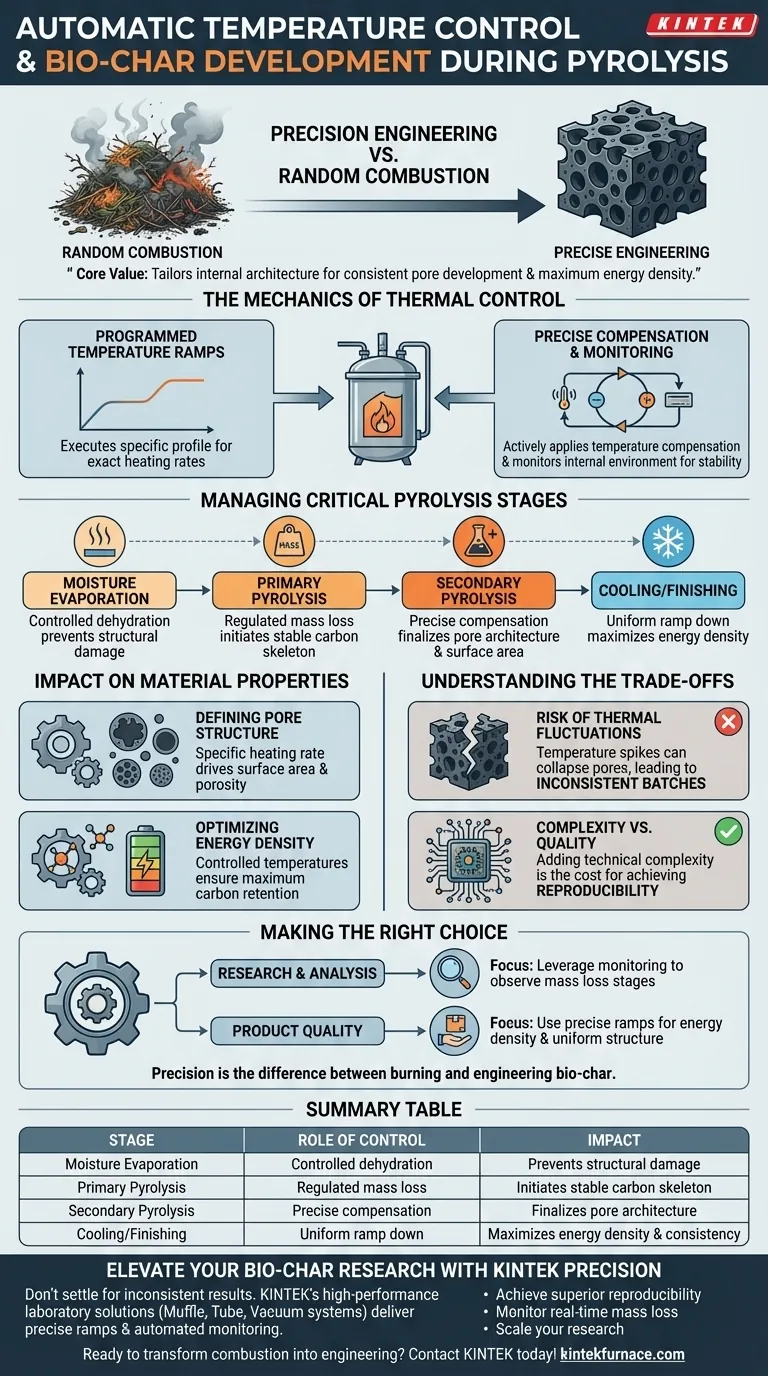

An automatic temperature control system fundamentally dictates the quality of bio-char by enforcing a specific, programmed temperature ramp throughout the pyrolysis process. By providing precise temperature compensation and real-time monitoring, the system governs exactly how the biomass loses mass, which directly shapes the physical structure and energy potential of the final product.

The core value of automated control is the transition from random combustion to precise engineering. It allows you to tailor the internal architecture of the bio-char, ensuring consistent pore development and maximum energy density.

The Mechanics of Thermal Control

Programmed Temperature Ramps

An automatic system does not simply apply heat; it executes a specific programmed profile.

This ensures the biomass is subjected to exact heating rates rather than fluctuating thermal conditions.

Precise Compensation and Monitoring

The system actively monitors the internal environment and applies temperature compensation.

This capability is critical for maintaining stability if the reaction becomes exothermic or if external conditions change.

Managing Critical Pyrolysis Stages

Observing Mass Loss Characteristics

Pyrolysis is defined by how and when the biomass loses weight.

An automated system allows for the detailed observation and control of these mass loss characteristics in real-time.

From Evaporation to Secondary Pyrolysis

The process occurs in distinct phases, beginning with moisture evaporation.

It then progresses through primary and secondary pyrolysis, where the chemical composition of the material fundamentally changes.

Impact on Material Properties

Defining Pore Structure

The specific heating rate applied by the control system is the primary driver of pore structure development.

By controlling how volatile gases escape the biomass, the system determines the surface area and porosity of the resulting char.

Optimizing Energy Density

The final energy density of the bio-char is a direct result of thermal precision.

Controlled temperatures ensure the maximum amount of carbon is retained while volatiles are efficiently removed.

Understanding the Trade-offs

The Risk of Thermal Fluctuations

Without an automatic control system, temperature spikes can collapse the pore structure.

While manual methods are cheaper, they often result in inconsistent batches that fail to meet specific energy or structural requirements.

Complexity vs. Product Quality

Implementing an automatic system adds technical complexity to the reactor setup.

However, this complexity is the necessary "cost" for achieving reproducibility in bio-char production.

Making the Right Choice for Your Goal

Whether you are conducting research or managing production, the level of control you utilize dictates your results.

- If your primary focus is Research and Analysis: Leverage the system's monitoring capabilities to observe distinct mass loss stages during primary and secondary pyrolysis.

- If your primary focus is Product Quality: Use precise temperature ramps to maximize energy density and ensure a uniform pore structure.

Precision in temperature control is the difference between burning biomass and engineering bio-char.

Summary Table:

| Stage of Pyrolysis | Role of Temperature Control | Impact on Bio-char Quality |

|---|---|---|

| Moisture Evaporation | Controlled dehydration | Prevents premature structural damage |

| Primary Pyrolysis | Regulated mass loss monitoring | Initiates stable carbon skeleton development |

| Secondary Pyrolysis | Precise temperature compensation | Finalizes pore architecture and surface area |

| Cooling/Finishing | Uniform thermal ramp down | Maximizes energy density and batch consistency |

Elevate Your Bio-char Research with KINTEK Precision

Don't settle for inconsistent results from manual thermal processes. KINTEK’s high-performance laboratory solutions, including advanced Muffle, Tube, and Vacuum systems, are engineered to deliver the precise temperature ramps and automated monitoring required for sophisticated pyrolysis.

Backed by expert R&D and world-class manufacturing, our customizable furnaces allow you to:

- Achieve superior reproducibility in energy density and pore structure.

- Monitor real-time mass loss and secondary pyrolysis stages.

- Scale your research with systems tailored to your unique biomass needs.

Ready to transform random combustion into precise engineering? Contact KINTEK today to find your ideal solution!

Visual Guide

References

- Hussien Elshareef, Yuguang Zhou. Investigation of Bio-Oil and Biochar Derived from Cotton Stalk Pyrolysis: Effect of Different Reaction Conditions. DOI: 10.3390/resources14050075

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the role of providing a uniform heating environment? Achieve Perfect Deep Eutectic Solvent Formation

- Why is a vacuum suction system required during the exhaust stage of rice straw-based charcoal carbonization?

- How do vacuum filtration systems operate in industrial sludge dehydration? Achieve Efficient Liquid-Solid Separation

- What are the technical advantages of using a quartz tube as a reaction chamber? Optimize g-C3N4 Thin Film CVD Processes

- What is the function of a laboratory hydraulic press in Al-Cr-Cu-Fe-Mn-Ni alloy formation? Maximize Green Strength

- Why are high-precision mass flow controllers necessary for h-BN CVD growth? Ensure Superior Film Stoichiometry

- Why is the laboratory water circulating vacuum pump particularly suitable for labs? Boost Efficiency and Safety in Your Lab

- How does chemical compatibility affect the selection of alumina ceramic furnace tubes? Ensure Longevity and Purity