Corundum (alumina) crucibles are chosen primarily for their exceptional chemical inertness and high refractoriness. In the specific context of LiScO2:Cr3+ synthesis, they withstand 1200°C environments without reacting with aggressive lithium-containing molten salts, ensuring the phosphor’s optical purity is preserved.

The synthesis of high-performance phosphors demands a vessel that disappears chemically. Corundum serves as this neutral barrier, allowing the material to complete its crystal phase construction without absorbing contaminants that would degrade near-infrared performance.

The Critical Role of Chemical Inertness

Resisting Molten Salt Erosion

At high temperatures, lithium compounds often turn into aggressive molten salts. These salts are notorious for corroding standard laboratory ceramics.

Corundum possesses a unique resistance to this specific form of chemical erosion. It prevents the vessel walls from degrading and mixing with the synthesis reactants.

Preventing Elemental Leaching

The primary danger during annealing is the leaching of container components into the sample. Even trace amounts of foreign elements can alter the stoichiometry of the phosphor.

By maintaining a robust barrier, corundum ensures that no container materials leach into the LiScO2:Cr3+ mixture. This guarantees the chemical composition remains exactly as intended.

Safeguarding Optical Performance

Protecting Crystal Phase Construction

For LiScO2:Cr3+ to function effectively, it must form a precise crystal structure. The presence of impurities during this "construction" phase creates defects.

Corundum provides the pure environment necessary for this phase to complete successfully. A pure crystal lattice is a prerequisite for high-efficiency luminescence.

Ensuring Near-Infrared Output

The ultimate goal of this synthesis is specific optical performance, particularly in the near-infrared range.

Impurities introduced by a reacting crucible often act as "quenching centers," absorbing energy rather than emitting light. Corundum eliminates this variable, directly supporting the material's optical quality.

High-Temperature Stability

Withstanding 1200°C Environments

The annealing process requires sustained exposure to temperatures around 1200°C.

Corundum is selected for its high refractoriness, meaning it retains structural integrity and chemical stability well beyond these operating temperatures. It does not soften or deform during the heating cycle.

Understanding the Trade-offs

Corundum vs. Metal Crucibles

While corundum is ideal for oxide and salt environments, it is not a universal solution for all lithium chemistries.

If the process involved active metallic lithium vapor rather than lithium salts, a tantalum (Ta) crucible would be required. Corundum is optimized for the oxidative environment of LiScO2 synthesis, whereas tantalum is superior for reducing environments where metallic corrosion is the primary threat.

Making the Right Choice for Your Goal

Selecting the correct crucible is about matching the vessel material to the chemical aggressiveness of your reactants.

- If your primary focus is Optical Purity: Prioritize corundum (alumina) to prevent container leaching and avoid impurity-driven quenching of the phosphor's light output.

- If your primary focus is High-Temperature Stability: Rely on corundum for processes up to 1200°C involving oxides or molten salts, where standard ceramics would fail.

- If your primary focus is Handling Metallic Lithium: Switch to Tantalum crucibles, as corundum may not withstand the corrosive nature of pure metallic lithium vapor.

The choice of corundum ensures that the rigorous conditions required to create LiScO2:Cr3+ do not compromise the delicate chemistry required for its performance.

Summary Table:

| Feature | Benefit for LiScO2:Cr3+ Synthesis |

|---|---|

| Chemical Inertness | Resists molten salt erosion and prevents elemental leaching into the phosphor. |

| High Refractoriness | Maintains structural integrity and stability at sustained temperatures of 1200°C. |

| Optical Safeguarding | Prevents "quenching centers" from impurities, ensuring high-efficiency NIR output. |

| Crystal Purity | Provides a neutral environment for precise crystal phase construction without defects. |

Elevate Your Material Synthesis with KINTEK Precision

Maximize the optical performance and chemical purity of your advanced phosphors with KINTEK’s specialized laboratory solutions. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable high-temperature furnaces and high-purity crucibles tailored to your unique research needs.

Don't let container contamination compromise your results. Contact our technical experts today to find the perfect thermal processing setup for your laboratory.

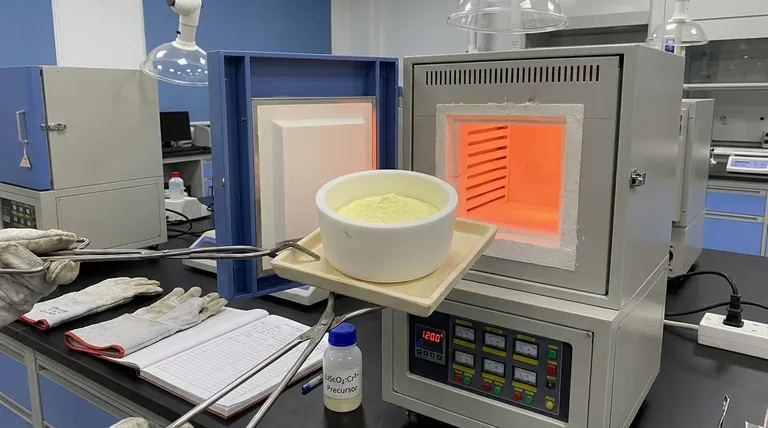

Visual Guide

References

- Leoni Frehmeyer, Thomas Jüstel. On the optimisation of the broadband NIR emitter LiScO2:Cr3+. DOI: 10.6001/chemija.2025.36.2.5

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the technical advantages of using high-purity quartz tubes? Optimize Heat and Purity in Combustion Analysis

- What is the key role of a grinder in the raw material preparation for magnesium evaporation and condensation experiments? Maximize Reactivity & Yield

- Why is a high-performance vacuum pump system necessary for AlV55 alloys? Ensure Aerospace-Grade Purity and Precision

- Why use high-performance insulation bricks in radiant tube simulations? Ensure precision and industrial accuracy.

- What is the role of a BN crucible in Ca0.5Sr0.5AlSiN3:Eu2+ synthesis? Achieve High-Purity Nitride Phosphors

- Why is a high-purity quartz boat selected for Tellurium purification? Achieve 5N+ Semiconductor Grade Results

- What role does an alumina crucible play during the gas nitriding process for stainless steel? Ensure Surface Purity

- What role do graphite molds play in the Spark Plasma Sintering (SPS)? Enhance Alumina Composite Performance