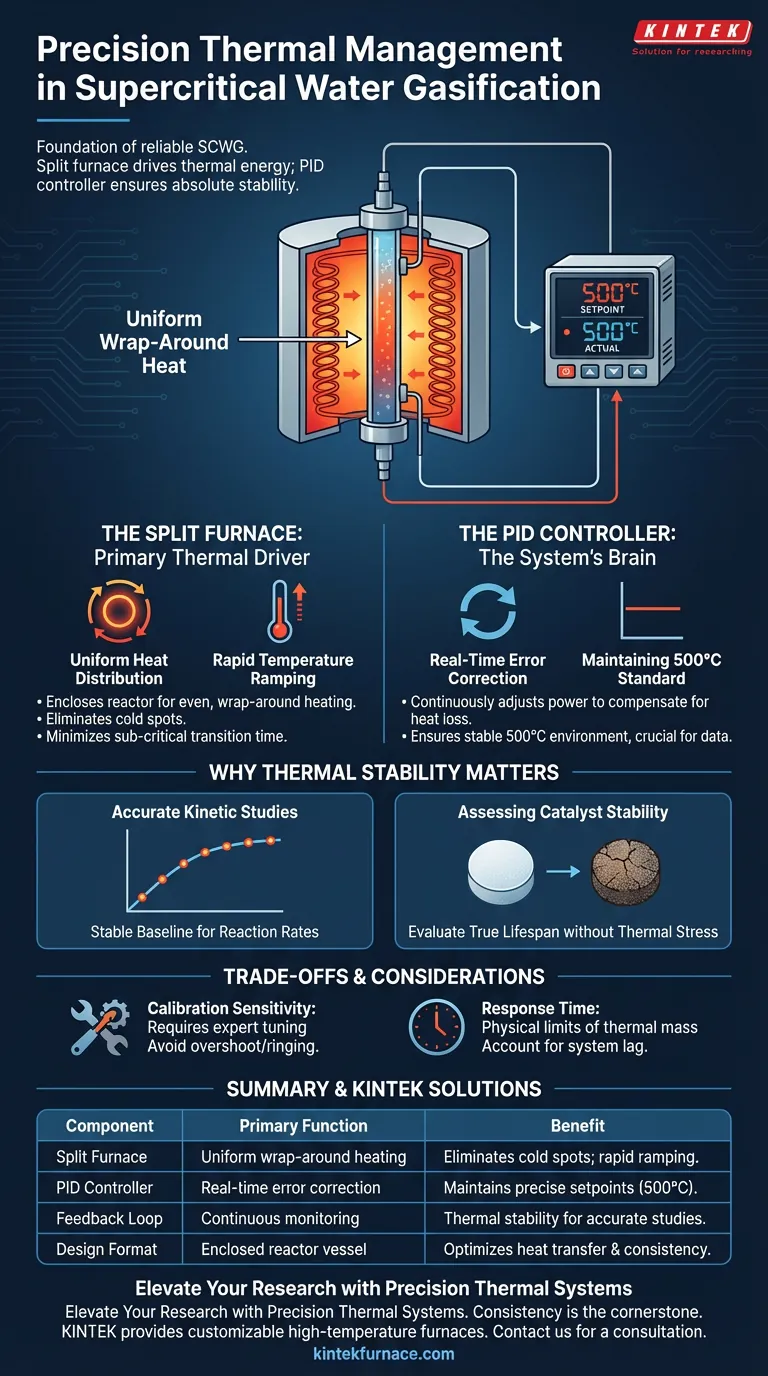

Precision thermal management is the foundation of reliable supercritical water gasification. A split furnace serves as the primary thermal driver, delivering uniform, wrap-around heat to rapidly elevate the reactor to supercritical temperatures. Acting as the system's brain, a high-precision PID (Proportional-Integral-Derivative) controller monitors this heat, providing real-time compensation for thermal losses to ensure absolute stability during the reaction.

In supercritical water gasification, reaching the target temperature is only half the battle; maintaining it against fluctuations is where success lies. The integration of a split furnace and PID controller ensures the thermal stability required to accurately study reaction kinetics and evaluate catalyst performance.

The Role of the Split Furnace

Achieving Uniform Heat Distribution

A split furnace is designed to enclose the reactor vessel completely. This "wrap-around" configuration ensures that heat is applied evenly from all sides.

By surrounding the reactor, the furnace eliminates cold spots that can occur with single-sided heating elements. This uniformity is essential for maintaining a consistent thermodynamic state throughout the fluid.

Rapid Temperature Ramping

Time is often a critical variable in gasification experiments. A split furnace is capable of generating intense thermal energy to raise the reactor temperature quickly.

This rapid ramp-up minimizes the time the fluid spends in sub-critical transition phases. It ensures the system reaches the target operating conditions efficiently.

The Role of the PID Controller

Real-Time Error Correction

While the furnace provides the raw power, the PID controller provides the finesse. It continuously compares the actual reactor temperature against the setpoint.

If the controller detects even a minor deviation—caused by heat loss to the environment or endothermic reaction steps—it instantly adjusts the power output. This creates a feedback loop that stabilizes the system in real time.

Maintaining the 500°C Standard

For this specific application, the system is often tasked with holding a constant temperature of 500 degrees Celsius.

At this temperature, water is well into its supercritical phase. The PID controller ensures the environment remains exactly at 500°C, rather than fluctuating between 490°C and 510°C, which would compromise the experimental data.

Why Thermal Stability Matters

Enabling Accurate Kinetic Studies

To model the kinetics of a chemical reaction, researchers must isolate variables. Temperature is the most critical variable to control.

If the temperature fluctuates, it becomes impossible to determine if a change in gas production is due to the chemical kinetics or a shift in thermal energy. The PID-controlled furnace removes this variable, providing a stable baseline for study.

Assessing Catalyst Stability

Catalysts are sensitive materials that can degrade or change behavior under thermal stress.

By ensuring a constant thermal environment, researchers can evaluate the true lifespan and efficiency of a catalyst. This setup allows for long-duration testing without thermal cycling artifacts skewing the results.

Understanding the Trade-offs

Calibration Sensitivity

While a PID controller is powerful, it is not "plug and play." It requires careful tuning of its Proportional, Integral, and Derivative parameters.

Improper tuning can lead to "overshoot" (heating beyond 500°C) or "ringing" (oscillating around the target). This requires operator expertise to configure correctly before experiments begin.

Response Time Limitations

The split furnace is a large thermal mass. Even with a smart controller, there is a physical limit to how fast the system can change temperature.

The controller can compensate for heat loss, but it cannot defy the laws of thermodynamics. Users must account for a slight lag between the controller's command and the furnace's physical response.

Making the Right Choice for Your Goal

To maximize the effectiveness of your supercritical water gasification system, align your equipment usage with your specific research objectives.

- If your primary focus is Kinetic Modeling: Prioritize the PID tuning to ensure the temperature variance is negligible, as this is the only way to derive accurate reaction rate constants.

- If your primary focus is Catalyst Durability: Utilize the split furnace's wrap-around capability to ensure the entire catalyst bed is heated uniformly, preventing localized hot or cold spots that could misrepresent catalyst life.

Ultimate consistency in temperature control is the only path to reproducible data in supercritical environments.

Summary Table:

| Component | Primary Function | Benefit to Supercritical Gasification |

|---|---|---|

| Split Furnace | Uniform wrap-around heating | Eliminates cold spots; ensures rapid temperature ramping. |

| PID Controller | Real-time error correction | Maintains precise setpoints (e.g., 500°C) against thermal loss. |

| Feedback Loop | Continuous monitoring | Provides thermal stability for accurate kinetic studies. |

| Design Format | Enclosed reactor vessel | Optimizes heat transfer and thermodynamic consistency. |

Elevate Your Research with Precision Thermal Systems

Consistency is the cornerstone of reproducible supercritical gasification data. KINTEK provides industry-leading thermal solutions backed by expert R&D and precision manufacturing.

Whether you require Muffle, Tube, Rotary, Vacuum, or CVD systems, our high-temperature lab furnaces are fully customizable to meet your unique reactor specifications. We empower researchers to eliminate thermal variables and focus on breakthrough kinetics and catalyst performance.

Ready to optimize your supercritical system?

Contact KINTEK today for a custom consultation

Visual Guide

References

- Kapil Khandelwal, Ajay K. Dalai. Catalytic Supercritical Water Gasification of Canola Straw with Promoted and Supported Nickel-Based Catalysts. DOI: 10.3390/molecules29040911

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What conditions does a continuous flow fixed-bed quartz reactor provide? Master CO Oxidation Testing with Cobalt Oxide

- How does a tube atmosphere furnace facilitate local CVD during PAN fiber carbonization? Master In-Situ CNT Growth

- What is the function of vacuum-sealed tubes and controlled heating? Master Ruthenium Precursor Embedding

- How do vacuum tube furnaces contribute to environmental protection and energy production? Discover Their Role in Clean Tech

- How does a two-zone tube furnace achieve stepwise control of precursors? Master CVD Heterostructure Growth

- Why is a quartz tube used for vacuum sealing GeTe synthesis? Ensure Material Purity and Stoichiometric Precision

- How does a tube furnace achieve energy efficiency? Optimize Heat Retention and Control

- What role does a tube resistance furnace play in AZO thin film production? Master Pre-Annealing for Perfect Layers