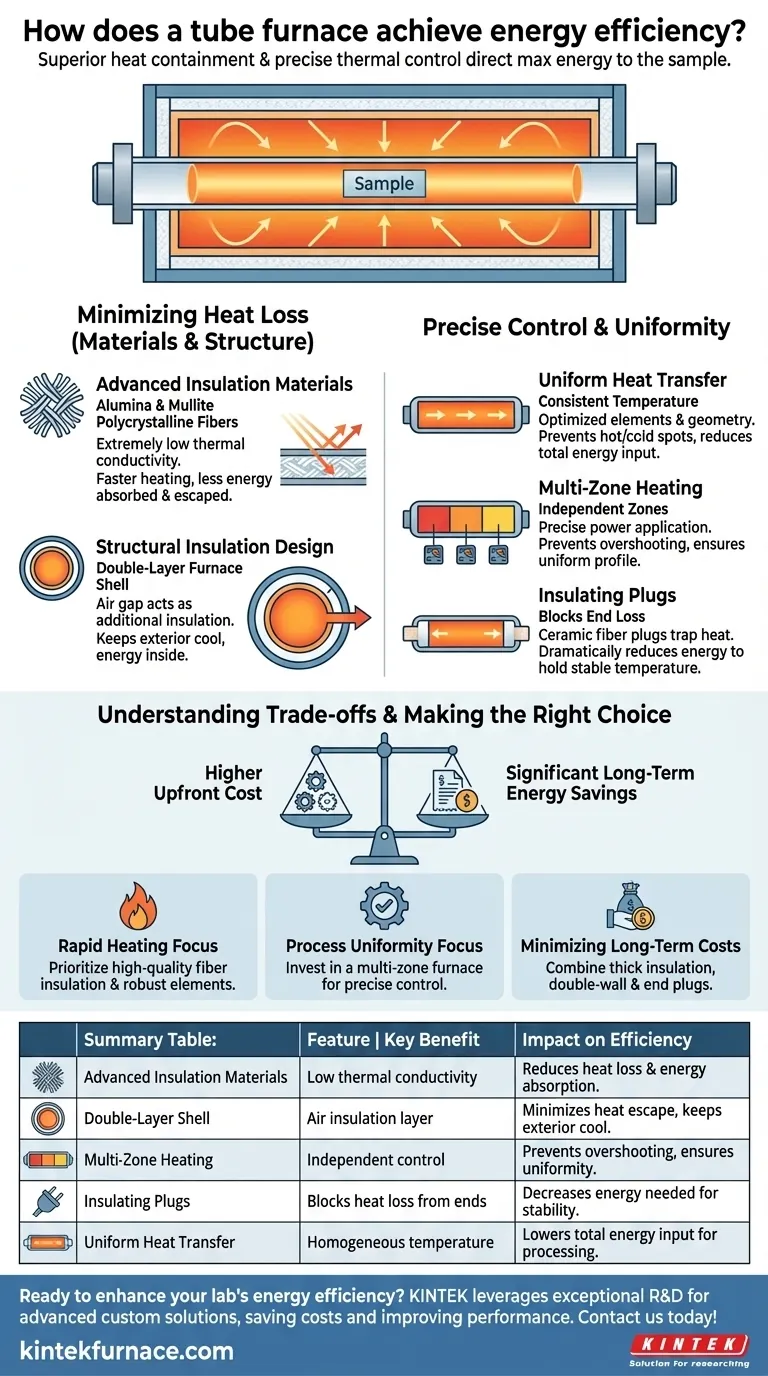

A tube furnace achieves its energy efficiency primarily through a combination of superior heat containment and precise thermal control. Its design focuses on generating heat effectively and, more importantly, preventing that heat from escaping into the surrounding environment, ensuring the maximum amount of energy is directed at the sample.

The core challenge in high-temperature work isn't just creating heat, but keeping it precisely where you need it. A tube furnace’s efficiency stems not from a single feature, but from a holistic design philosophy focused on minimizing thermal waste through advanced insulation, structural design, and intelligent control.

The Core Principle: Minimizing Heat Loss

The most significant factor in a furnace's energy consumption is wasted heat. An efficient tube furnace is engineered specifically to combat this loss through two main avenues: materials and structure.

Advanced Insulation Materials

The choice of insulation is paramount. Modern tube furnaces move away from traditional heavy firebricks toward advanced, low-thermal-mass materials.

High-quality materials like alumina polycrystalline fibers or polycrystalline mullite fibers are used. These have extremely low thermal conductivity, meaning they are very poor at transferring heat.

This allows the furnace chamber to heat up quickly, as less energy is absorbed by the insulation itself. It also means less heat escapes the furnace, significantly reducing the power required to maintain a set temperature.

Structural Insulation Design

Beyond the material itself, the physical construction of the furnace plays a vital role.

Many high-efficiency models feature a double-layer furnace shell. This design creates an air gap between the inner and outer walls of the furnace.

This gap acts as an additional layer of insulation—a principle known as air insulation. This structure dissipates heat before it can reach the outer surface, keeping the exterior cool and the energy inside.

The Role of Precise Control and Uniformity

Wasted energy also comes from inefficient heating patterns and poor temperature management. Efficiency is gained by applying heat intelligently.

Uniform Heat Transfer

Ensuring a consistent temperature throughout the entire heated zone is crucial. If a furnace has significant hot and cold spots, it must work harder and longer to ensure the entire sample reaches the target temperature.

Efficient designs use optimized heating elements and chamber geometry to promote homogeneous heat transfer, treating the entire sample evenly and completing the process with less total energy input.

Multi-Zone Heating

For longer tubes or more sensitive processes, multi-zone furnaces offer a significant efficiency advantage.

Instead of one large heating element, the furnace is divided into several smaller, independently controlled zones. This allows the system to apply power precisely where it's needed to maintain a uniform temperature profile or create a specific gradient. It prevents the common issue of a single-zone furnace overshooting the temperature to compensate for heat loss at the ends.

Insulating Plugs

A simple but highly effective feature is the use of insulating plugs or radiation shields.

A significant amount of heat is lost through the open ends of the process tube. By inserting high-temperature ceramic fiber plugs at each end, you physically block this major pathway for heat escape, dramatically reducing the energy needed to hold a stable temperature.

Understanding the Trade-offs

While efficiency is a primary goal, it is balanced against other performance and cost factors.

Upfront Cost vs. Operational Cost

Furnaces with the most advanced insulation materials, multi-zone controllers, and double-wall construction have a higher initial purchase price.

However, this initial investment is often recovered over the furnace's lifetime through significant savings in energy consumption, especially in high-use industrial or research environments.

Application Requirements

The "most efficient" furnace is relative to your specific application. A furnace optimized for a stable 800°C process may not be the most efficient choice for rapid cycling to 1500°C.

Factors like your target temperature, required uniformity, and process duration all influence which design features will provide the most meaningful energy savings for you.

Making the Right Choice for Your Goal

To select the right furnace, align its features with your primary objective.

- If your primary focus is rapid heating and high temperatures: Prioritize a furnace with high-quality, low-thermal-mass fiber insulation and robust heating elements.

- If your primary focus is process uniformity for sensitive materials: Invest in a multi-zone furnace to guarantee precise temperature control along the entire sample length.

- If your primary focus is minimizing long-term operational costs: Look for the combination of thick insulation, double-wall construction, and well-sealed insulating end plugs.

By understanding these core design principles, you can select a furnace that not only meets your technical needs but also functions as a cost-effective asset for years to come.

Summary Table:

| Feature | Key Benefit | Impact on Efficiency |

|---|---|---|

| Advanced Insulation Materials | Low thermal conductivity | Reduces heat loss and energy absorption |

| Double-Layer Furnace Shell | Air insulation layer | Minimizes heat escape, keeps exterior cool |

| Multi-Zone Heating | Independent temperature control | Prevents overshooting, ensures uniform heating |

| Insulating Plugs | Blocks heat loss from tube ends | Decreases energy needed for temperature stability |

| Uniform Heat Transfer | Homogeneous temperature distribution | Lowers total energy input for sample processing |

Ready to enhance your lab's energy efficiency with a custom tube furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, helping you save on operational costs and improve performance. Contact us today to discuss how we can support your specific goals!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety