At a high level, PECVD systems are categorized by how they generate and apply plasma to a substrate. The primary types are Direct PECVD, where plasma is in contact with the substrate, and Remote PECVD, where plasma is generated away from it, with hybrid systems like High-Density PECVD (HDPECVD) combining elements of both.

The choice of a PECVD system is not about finding the "best" type, but about matching the plasma generation method and system configuration to the specific material properties, deposition rate, and substrate sensitivity your application demands.

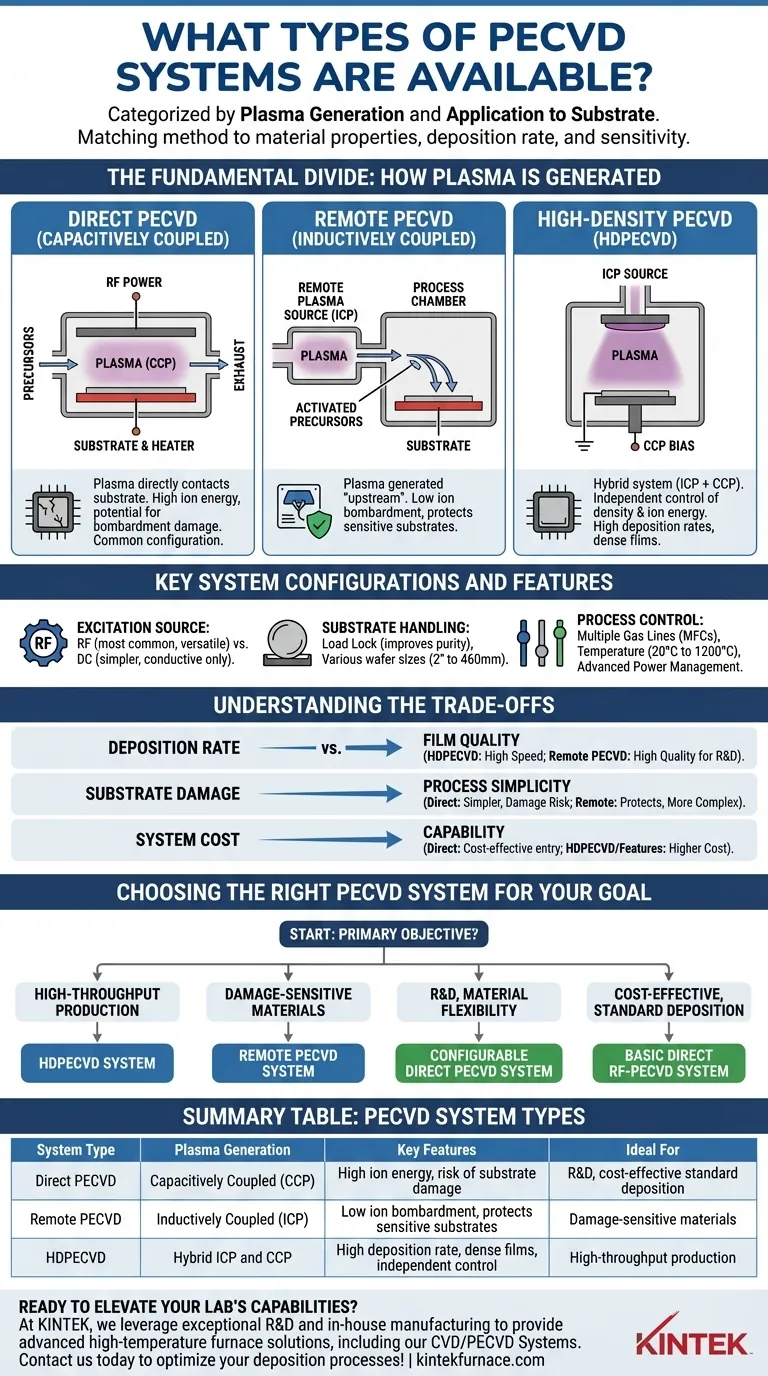

The Fundamental Divide: How Plasma is Generated

The most critical distinction between PECVD systems is the location and method of plasma generation relative to the substrate. This choice directly impacts film quality, deposition rate, and potential substrate damage.

Direct PECVD (Capacitively Coupled)

Direct PECVD is a common configuration where the substrate is placed directly between two electrodes, becoming part of the plasma-generating circuit. This is also known as a capacitively coupled plasma (CCP) system.

The plasma is in direct contact with the growing film. This proximity allows for high ion energy, which can be beneficial for densifying the film, but also carries a risk of ion bombardment damage.

Remote PECVD (Inductively Coupled)

In a Remote PECVD system, the plasma is generated "upstream" or outside of the main process chamber, typically using an inductively coupled plasma (ICP) source.

Gaseous precursors are activated in this remote plasma and then flow into the chamber to deposit on the substrate. This separation dramatically reduces ion bombardment, making it ideal for depositing films on sensitive electronic or optical substrates where damage must be minimized.

High-Density PECVD (HDPECVD)

HDPECVD is an advanced hybrid system designed for high-quality, high-rate deposition. It combines an inductively coupled source to generate a very dense plasma with a separate capacitively coupled bias on the substrate holder.

This dual approach provides independent control over plasma density (via the ICP) and ion energy (via the CCP bias). The result is a process that can achieve dense, high-quality films at much faster rates than conventional PECVD.

Key System Configurations and Features

Beyond the core plasma generation method, PECVD systems are defined by a range of configurable hardware components that dictate their capabilities.

Excitation Source: RF vs. DC

The plasma can be excited using different power sources. Radio Frequency (RF) fields are most common, as they can effectively generate plasma from both conductive and insulating materials. Direct Current (DC) fields are simpler but are generally limited to processes involving conductive targets.

Substrate Handling and Chamber Integrity

Systems are built to handle specific substrate sizes, with common configurations for 2-inch, 4-inch, 6-inch, and even larger wafers up to 460mm.

A critical feature is the load lock, a small antechamber that allows wafers to be moved in and out of the main process chamber without exposing it to the ambient atmosphere. This dramatically improves film purity and process repeatability.

Process Control: Gas, Temperature, and Power

Modern PECVD systems offer precise control over key variables. This includes:

- Gas Delivery: Multiple gas lines (4, 8, or even 12) managed by mass flow controllers (MFCs) allow for complex film chemistries and the introduction of dopants.

- Temperature Control: Substrate stages can be heated or cooled, with typical ranges from 20°C to 400°C and specialized options reaching 1200°C.

- Power Management: Advanced RF switching can be used to modulate the plasma and actively control film properties like mechanical stress.

Understanding the Trade-offs

Choosing a PECVD system involves balancing competing priorities of performance, quality, and cost.

Deposition Rate vs. Film Quality

There is often a trade-off between speed and perfection. HDPECVD offers the highest deposition rates, which is ideal for manufacturing. However, for some sensitive R&D applications, a slower, more controlled deposition in a Remote PECVD system may yield superior film properties.

Substrate Damage vs. Process Simplicity

Direct PECVD is a simpler, more established process, but the direct plasma contact risks damaging sensitive substrates. Remote PECVD explicitly solves this problem but introduces additional system complexity and cost.

System Cost vs. Capability

A basic, direct RF-PECVD system is the most cost-effective entry point. Each additional feature—such as a load lock, expanded temperature range, additional gas lines, or an HDPECVD source—significantly increases the system's price and maintenance overhead.

Choosing the Right PECVD System for Your Goal

Your choice should be driven by a clear understanding of your primary objective.

- If your primary focus is high-throughput production: An HDPECVD system is the logical choice for its unmatched deposition speed and high film density.

- If your primary focus is depositing on damage-sensitive materials: A Remote PECVD system provides the best protection against ion bombardment, ensuring the integrity of your substrate.

- If your primary focus is R&D and material flexibility: A highly configurable Direct PECVD system with multiple gas lines, wide temperature control, and advanced power management offers the most versatility.

- If your primary focus is cost-effective, standard film deposition: A basic Direct RF-PECVD system provides a reliable and proven solution for common materials like silicon oxides and nitrides.

Understanding these core system types and their underlying principles empowers you to select the precise tool required to achieve your material science or fabrication goals.

Summary Table:

| System Type | Plasma Generation | Key Features | Ideal For |

|---|---|---|---|

| Direct PECVD | Capacitively coupled (CCP) | High ion energy, risk of substrate damage | R&D, cost-effective standard deposition |

| Remote PECVD | Inductively coupled (ICP) | Low ion bombardment, protects sensitive substrates | Damage-sensitive materials |

| High-Density PECVD (HDPECVD) | Hybrid ICP and CCP | High deposition rate, dense films, independent control | High-throughput production |

Ready to elevate your lab's capabilities with a tailored PECVD system? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including our CVD/PECVD Systems. Whether you're focused on high-throughput production, protecting sensitive substrates, or flexible R&D, our strong deep customization capability ensures we meet your unique experimental needs. Don't settle for one-size-fits-all—contact us today to discuss how we can optimize your deposition processes and drive your research forward!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What is PECVD specification? A Guide to Choosing the Right System for Your Lab

- How does chemical vapour deposition (CVD) differ from PVD? Key Differences in Thin-Film Coating Methods

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition

- What is plasma-deposited silicon nitride, and what are its properties? Discover Its Role in Solar Cell Efficiency

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties