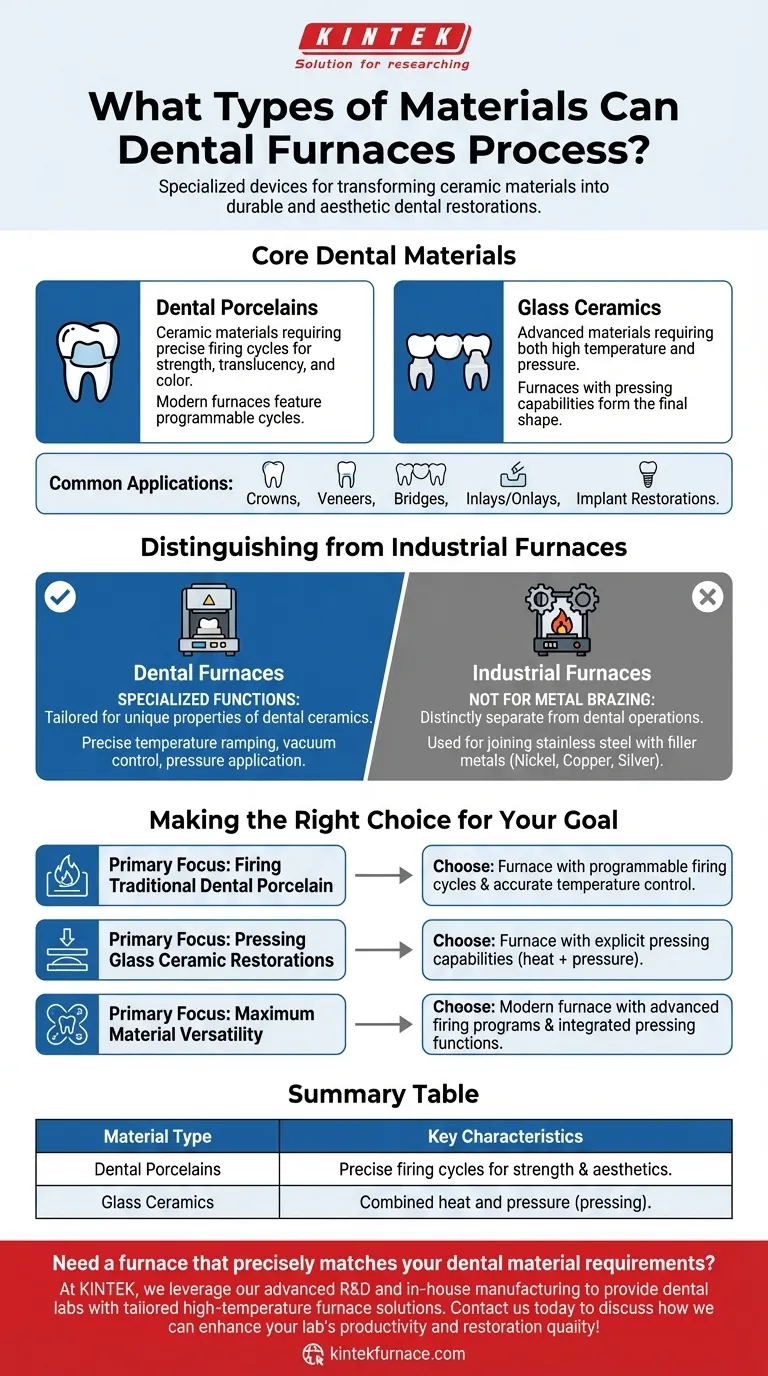

Dental furnaces primarily process a range of ceramic materials, including dental porcelains and specialized glass ceramics, essential for creating durable and aesthetic dental restorations. These sophisticated devices utilize precise temperature control and, in some cases, pressure, to transform raw materials into final products like crowns, veneers, and bridges.

Dental furnaces are engineered for specific ceramic and glass-ceramic materials, employing distinct processes like firing and pressing. Understanding these material capabilities is crucial for ensuring the quality and integrity of dental prosthetics.

The Core Materials for Dental Restorations

Dental furnaces are purpose-built to handle materials critical for restorative dentistry. Their design accommodates the unique thermal and pressure requirements of these substances.

Dental Porcelains

These are a fundamental category of ceramic materials widely used in dentistry. Dental porcelains require precise firing cycles to achieve their desired strength, translucency, and color. Modern porcelain furnaces feature programmable cycles to ensure optimal results for these materials.

Glass Ceramics

Beyond traditional porcelains, some advanced dental furnaces are also capable of processing glass ceramics. These materials often require both high temperatures and pressure to be formed into their final shape. Furnaces designed for this process can generate the necessary pressure to "press" the glass ceramics.

Distinguishing Dental Furnaces from Industrial Furnaces

It's important to differentiate dental furnace applications from other industrial furnace uses. The material compatibility of a dental furnace is highly specialized.

Not for Metal Brazing

While some industrial furnaces perform furnace brazing, this process is distinctly separate from dental furnace operations. Furnace brazing commonly joins stainless steel components using filler metals like nickel, copper, and silver. Dental furnaces are not designed for these metallic applications.

Specialized Functions for Dental Work

The design and function of dental furnaces are tailored specifically for the unique properties of dental ceramics. This includes precise temperature ramping, vacuum control during firing, and pressure application for certain materials. These capabilities are distinct from those required for industrial metalworking.

Making the Right Choice for Your Goal

Selecting or utilizing a dental furnace effectively depends on the materials you intend to process and the desired outcome.

- If your primary focus is firing traditional dental porcelain restorations: Ensure the furnace offers programmable firing cycles and accurate temperature control suitable for various porcelain types.

- If your primary focus is pressing glass ceramic restorations: Look for furnaces explicitly designed with pressing capabilities that can apply the necessary pressure alongside heat.

- If your primary focus is maximum material versatility in dental ceramics: Opt for a modern furnace that combines both advanced firing programs for porcelains and integrated pressing functions for glass ceramics.

Dental furnaces are indispensable tools, precisely engineered to bring life and function to ceramic and glass-ceramic dental materials.

Summary Table:

| Material Type | Key Characteristics | Common Applications |

|---|---|---|

| Dental Porcelains | Require precise firing cycles for strength and aesthetics. | Crowns, Veneers, Inlays/Onlays |

| Glass Ceramics | Often require combined heat and pressure (pressing). | Crowns, Bridges, Implant Restorations |

Need a furnace that precisely matches your dental material requirements? At KINTEK, we leverage our advanced R&D and in-house manufacturing to provide dental labs with tailored high-temperature furnace solutions. Whether you specialize in firing porcelains or pressing glass-ceramics, our deep customization capabilities ensure your equipment meets the exact demands of your restorations. Contact us today to discuss how we can enhance your lab's productivity and restoration quality!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations