Indirect-fired rotary kilns are specifically designed to process high-value, sensitive materials where product purity and atmospheric control are non-negotiable. They are commonly used for materials such as specialty chemicals, battery components, catalysts, phosphors, and precious metals that cannot tolerate direct contact with combustion byproducts.

The core principle of an indirect-fired kiln is heating the material without direct contact from flame or flue gas. This fundamental separation makes it the ideal choice for applications demanding a strictly controlled atmosphere to prevent contamination and achieve precise chemical reactions.

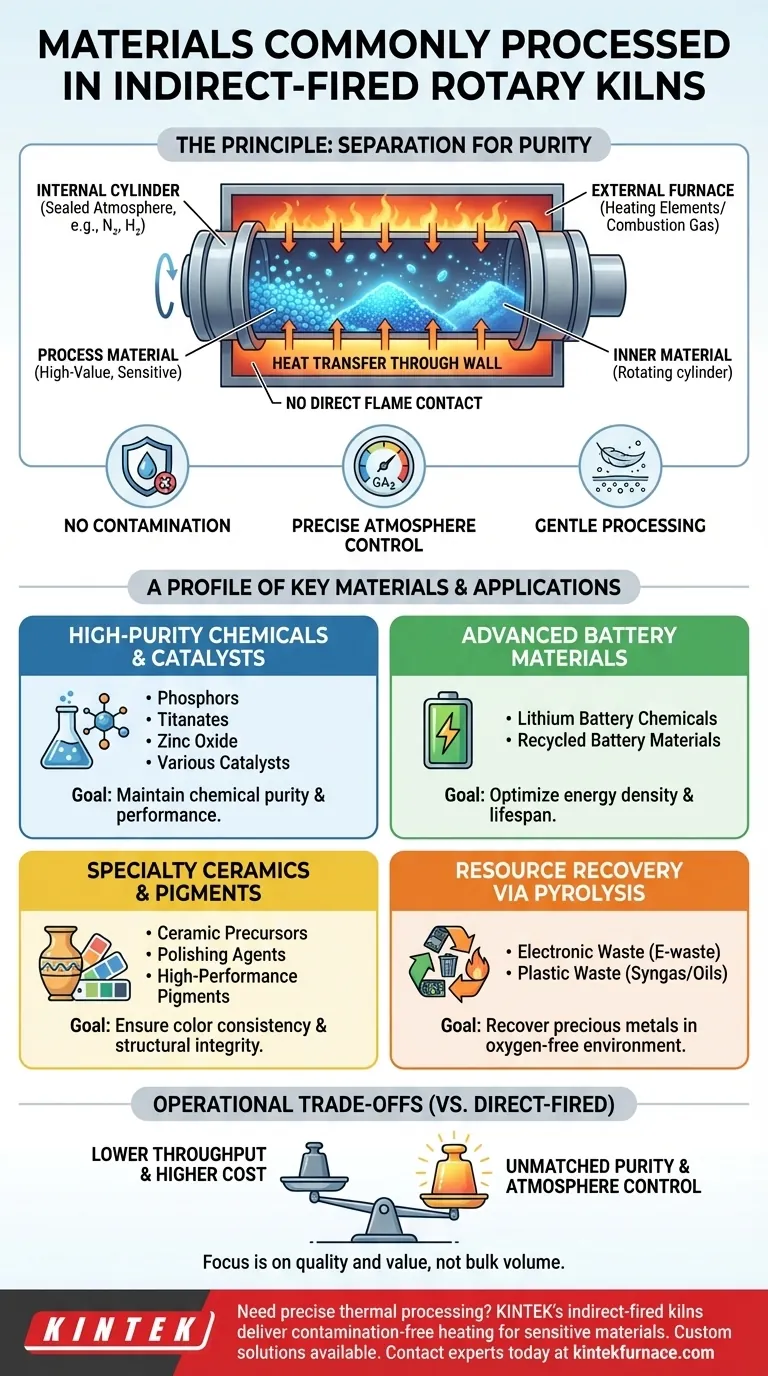

Why Choose an Indirect-Fired Kiln? The Principle of Separation

The defining characteristic of an indirect-fired kiln is its design. A rotating cylinder containing the process material is housed within a furnace or surrounded by heating elements. Heat is transferred through the cylinder wall to the material inside, rather than by direct contact.

Preventing Product Contamination

Because the heating source (e.g., combustion gas) remains on the outside of the processing cylinder, there is no risk of it mixing with and contaminating the material.

This is critical for high-purity products like specialty chemicals, pharmaceutical precursors, and electronic-grade materials where even trace impurities can render the final product unusable.

Achieving Precise Atmosphere Control

The sealed nature of the internal cylinder allows for complete control over the processing atmosphere.

Specific gases—such as nitrogen for an inert environment or hydrogen for a reducing one—can be introduced. This enables complex chemical reactions like calcination, reduction, and pyrolysis that would be impossible in a direct-fired system.

Processing Sensitive and Fine Materials

The kiln's gentle tumbling action combined with the absence of direct flame impingement is ideal for delicate or finely powdered materials.

This includes powders, granulates, and suspensions that could otherwise be damaged or blown out of the system by the high gas velocities found in direct-fired kilns.

A Profile of Commonly Processed Materials

The unique capabilities of indirect-fired kilns make them essential for several key industries. The common thread among these materials is a need for precision thermal processing in a controlled, clean environment.

High-Purity Chemicals and Catalysts

Materials like phosphors, titanates, zinc oxide, and various catalysts demand a pristine processing environment to maintain their chemical structure and performance. The indirect kiln ensures their properties are not altered by unwanted reactions with combustion gases.

Advanced Battery Materials

The performance of modern batteries is highly dependent on the purity and crystalline structure of their components.

Indirect kilns are used to process lithium battery chemicals and recycled battery materials, providing the precise temperature control needed to create materials with optimal energy density and lifespan.

Specialty Ceramics and Pigments

For ceramic precursors, polishing agents, and high-performance pigments, color and structural integrity are paramount. The controlled heating and atmosphere prevent discoloration and ensure a consistent, high-quality final product.

Resource Recovery via Pyrolysis

Indirect kilns excel at pyrolysis, the thermal decomposition of material in an oxygen-free environment.

This process is used to treat electronic waste to recover precious metals, or to break down plastic waste into valuable syngas and oils. The sealed environment is essential for preventing combustion and maximizing yield.

Understanding the Operational Trade-offs

While powerful, the indirect-fired kiln is a specialized tool with specific trade-offs compared to its direct-fired counterparts. Understanding these is key to making an informed decision.

Lower Throughput Capacity

Indirect kilns are generally designed for processing smaller quantities of material, often in the range of 1 to 20 tons per hour. The focus is on the quality and value of the material, not bulk volume.

Higher Capital and Operating Costs

The use of high-temperature, heat-resistant alloy shells and a more complex external heating system results in higher initial investment and maintenance costs. This cost is justified by the production of high-value, specialized products.

Heat Transfer Limitations

Transferring heat through the wall of the rotating shell is inherently less efficient than direct flame contact. This can lead to longer residence times and places a premium on engineered designs with multiple, independent heating zones to ensure precise temperature profiles.

Aligning the Kiln with Your Processing Goal

When selecting a thermal processing technology, your primary objective determines the best fit.

- If your primary focus is absolute material purity and precise chemical reactions: An indirect-fired kiln is the superior choice, essential for producing catalysts, battery materials, and specialty chemicals.

- If your primary focus is high-volume, low-cost bulk processing: A direct-fired kiln is typically more economical for materials like cement, lime, or bulk minerals where direct contact with flue gas is acceptable.

- If your primary focus is thermal decomposition for resource recovery: An indirect-fired kiln provides the controlled, oxygen-free atmosphere necessary for efficient pyrolysis of waste streams.

Ultimately, the decision hinges on whether your process values absolute atmospheric control and product purity over maximum throughput.

Summary Table:

| Material Category | Key Examples | Primary Processing Goal |

|---|---|---|

| High-Purity Chemicals & Catalysts | Phosphors, titanates, zinc oxide | Maintain chemical purity and performance |

| Advanced Battery Materials | Lithium battery chemicals, recycled materials | Optimize energy density and lifespan |

| Specialty Ceramics & Pigments | Ceramic precursors, polishing agents | Ensure color consistency and structural integrity |

| Resource Recovery via Pyrolysis | Electronic waste, plastic waste | Recover precious metals or produce syngas/oils |

Need precise thermal processing for high-value materials? KINTEK's indirect-fired rotary kilns deliver contamination-free heating and exact atmosphere control—perfect for sensitive materials like specialty chemicals, battery components, and catalysts. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for unique needs. Contact our experts today to discuss your application!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

People Also Ask

- How does a rotary furnace compare to a fixed-bed furnace for powder? Optimize Uniformity in Large-Scale Production

- What is the significance of rotation in a pyrolysis rotary kiln reactor? Unlock Efficient Waste-to-Energy Conversion

- What are the advantages of a rotary kiln for bio-reductants? Achieve Industrial-Scale Uniformity and Scalability

- Why is an industrial-grade rotary reactor necessary in the oil sludge pyrolysis process? Maximize Yield & Efficiency

- How do pyrolysis rotary kiln reactors function? Unlock Efficient Waste-to-Value Conversion