At its core, a pyrolysis rotary kiln reactor is a large, rotating, and slightly inclined cylinder designed to thermally decompose materials like waste tires in an oxygen-free environment. As the drum rotates, the material tumbles and moves continuously from the higher inlet to the lower outlet, ensuring every particle is heated evenly to between 400–600°C. This process breaks down the waste into valuable products such as fuel oil, carbon black, and steel wire.

The effectiveness of a pyrolysis rotary kiln lies in its elegant use of simple mechanics. The slow, inclined rotation simultaneously achieves three critical functions: continuous material transport, uniform heat exposure, and the maintenance of a controlled atmosphere required for pyrolysis.

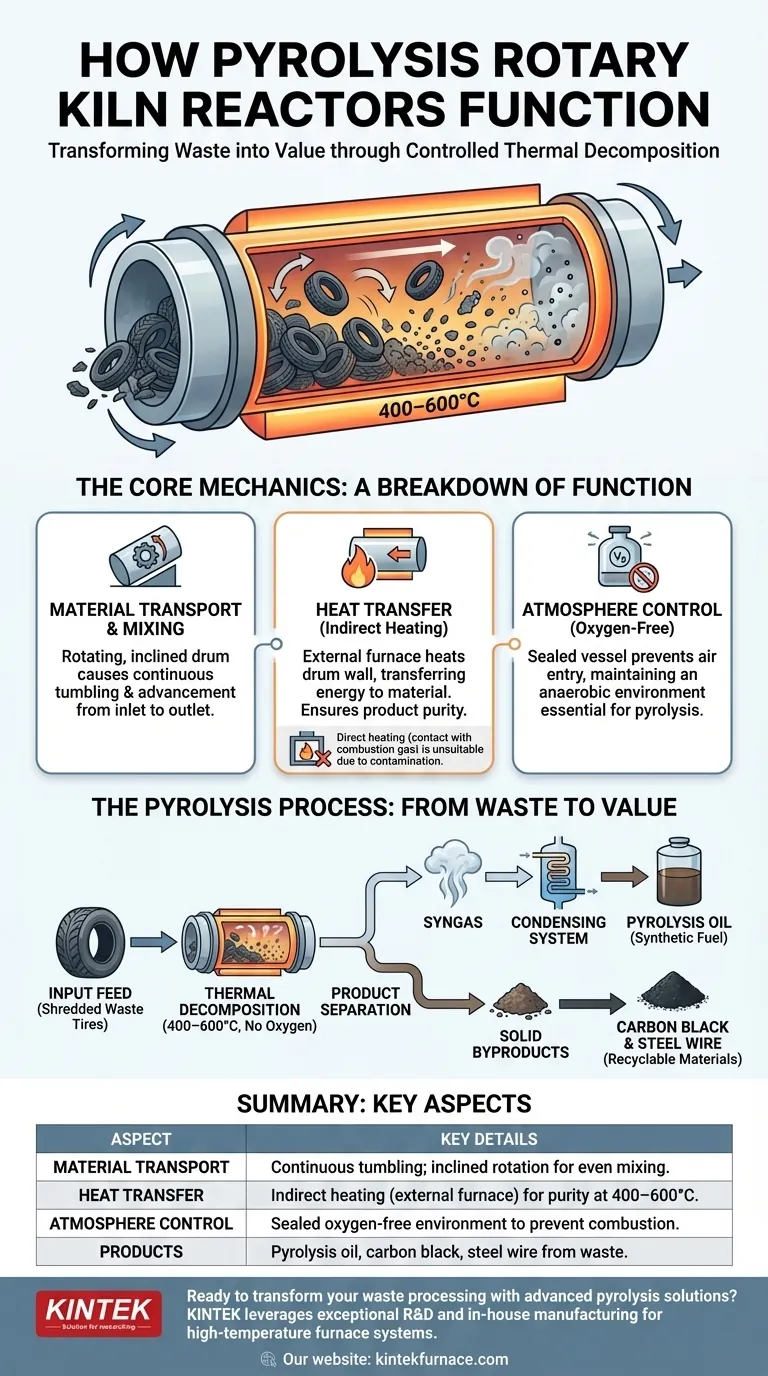

The Core Mechanics: A Breakdown of Function

To understand how a rotary kiln achieves this transformation, we must look at its three fundamental operating principles: material transport, heat transfer, and atmosphere control.

Material Transport and Mixing

The kiln is a long cylindrical drum positioned at a slight horizontal angle. Material is fed into the higher end.

As the drum rotates slowly, the material inside is lifted by the drum's wall and then tumbles back down. This continuous tumbling action ensures the material is thoroughly mixed.

This rotation, combined with the slight inclination, causes the material to gradually advance through the length of the kiln, moving from the inlet to the discharge end. This creates a continuous, automated process.

Heat Transfer: The Engine of Decomposition

Heat is the catalyst for the pyrolysis reaction. The method of applying this heat is a critical design choice and typically falls into two categories.

Indirect heating is the most common method for pyrolysis. The rotating drum is heated from the outside by an external furnace, which can be powered by gas burners or electric elements. The heat transfers through the steel wall of the drum to the material inside. This method is crucial for keeping the pyrolysis products pure.

Direct heating, where hot gases from combustion pass through the inside of the drum in direct contact with the material, is less common for pyrolysis. While thermally efficient, it risks contaminating the final products with combustion byproducts and introducing oxygen, which would disrupt the pyrolysis process.

Atmosphere Control: The Key to Pyrolysis

Pyrolysis is, by definition, thermal decomposition in the absence of oxygen. If oxygen were present at these high temperatures, the material would simply burn (combust) rather than chemically break down.

The rotary kiln is a sealed vessel. This design is essential for preventing air from entering and for containing the valuable gases produced during the reaction. The sealed environment ensures a strictly anaerobic (oxygen-free) atmosphere is maintained, allowing pyrolysis to occur correctly.

The Pyrolysis Process: From Waste to Value

With the core mechanics understood, the step-by-step process for converting waste tires becomes clear.

The Input Feed

Shredded waste tires are continuously fed into the upper end of the rotating kiln. Shredding increases the surface area, which improves the efficiency of heat transfer.

Thermal Decomposition

As the tires tumble and travel through the heated zone (400–600°C), the long-chain hydrocarbon molecules that make up the rubber are broken down. They vaporize into smaller, lighter molecules, forming a hot gas known as syngas.

Product Separation and Collection

This syngas is piped out of the kiln and directed to a condensing system, where it cools and liquefies into pyrolysis oil (a type of synthetic fuel).

The solid materials that do not vaporize, such as carbon black and the steel wire from the tire's structure, continue to travel to the end of the kiln. They are discharged from the lower end as solid byproducts, ready for collection and recycling.

Understanding the Key Trade-off: Indirect vs. Direct Heating

The choice of heating method is the single most important design decision, directly impacting product quality and system complexity.

Indirect Heating: Purity and Control

This is the standard for high-quality pyrolysis. By heating the drum externally, the internal atmosphere remains pure and free of combustion gases. This ensures the resulting pyrolysis oil and carbon black are not contaminated and meet higher quality standards. It also allows for more precise temperature control.

Direct Heating: Efficiency and Simplicity

Allowing hot gases to flow directly over the material transfers heat more rapidly. However, this method is generally unsuitable for pyrolysis because it introduces contaminants and makes maintaining an oxygen-free environment extremely difficult. It is more common in processes like drying minerals or cement production, where product purity is less sensitive.

How to Apply This Knowledge

Understanding these principles helps you evaluate the suitability of a rotary kiln for a specific goal.

- If your primary focus is process uniformity: The tumbling action caused by the kiln's rotation is the key feature, as it eliminates hot spots and ensures every particle receives equal heat treatment.

- If your primary focus is high-quality products: An indirectly heated design is non-negotiable. It is the only way to guarantee a pure, oxygen-free internal atmosphere needed for clean pyrolysis.

- If your primary focus is continuous, industrial-scale throughput: The inclined, rotating drum design is inherently built for automated, continuous material flow, making it superior to batch-based systems for large volumes.

Ultimately, the pyrolysis rotary kiln is a powerful example of how fundamental engineering principles are combined to solve a complex environmental and industrial challenge.

Summary Table:

| Aspect | Key Details |

|---|---|

| Material Transport | Continuous tumbling via inclined, rotating drum for even mixing and movement from inlet to outlet. |

| Heat Transfer | Indirect heating (external furnace) for purity; temperatures of 400–600°C to decompose materials. |

| Atmosphere Control | Sealed vessel maintains oxygen-free environment to prevent combustion and enable pyrolysis. |

| Products | Outputs include pyrolysis oil, carbon black, and steel wire from waste like tires. |

Ready to transform your waste processing with advanced pyrolysis solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide high-temperature furnace systems, including Rotary Furnaces and CVD/PECVD Systems, tailored for diverse laboratory needs. Our deep customization capabilities ensure precise alignment with your unique experimental requirements, enhancing efficiency and product quality. Contact us today to discuss how our solutions can benefit your operations!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What technical requirements are placed on heating equipment for fast pyrolysis? Master High-Yield Bio-Oil Production

- Why must precise temperature measurement and upper-limit control be implemented during the rotary furnace melting of ductile iron?

- Why is an industrial-grade rotary reactor necessary in the oil sludge pyrolysis process? Maximize Yield & Efficiency

- What are the advantages of a rotary kiln for bio-reductants? Achieve Industrial-Scale Uniformity and Scalability

- What is the working principle of a pyrolysis rotary kiln reactor? Efficient Waste-to-Energy Conversion