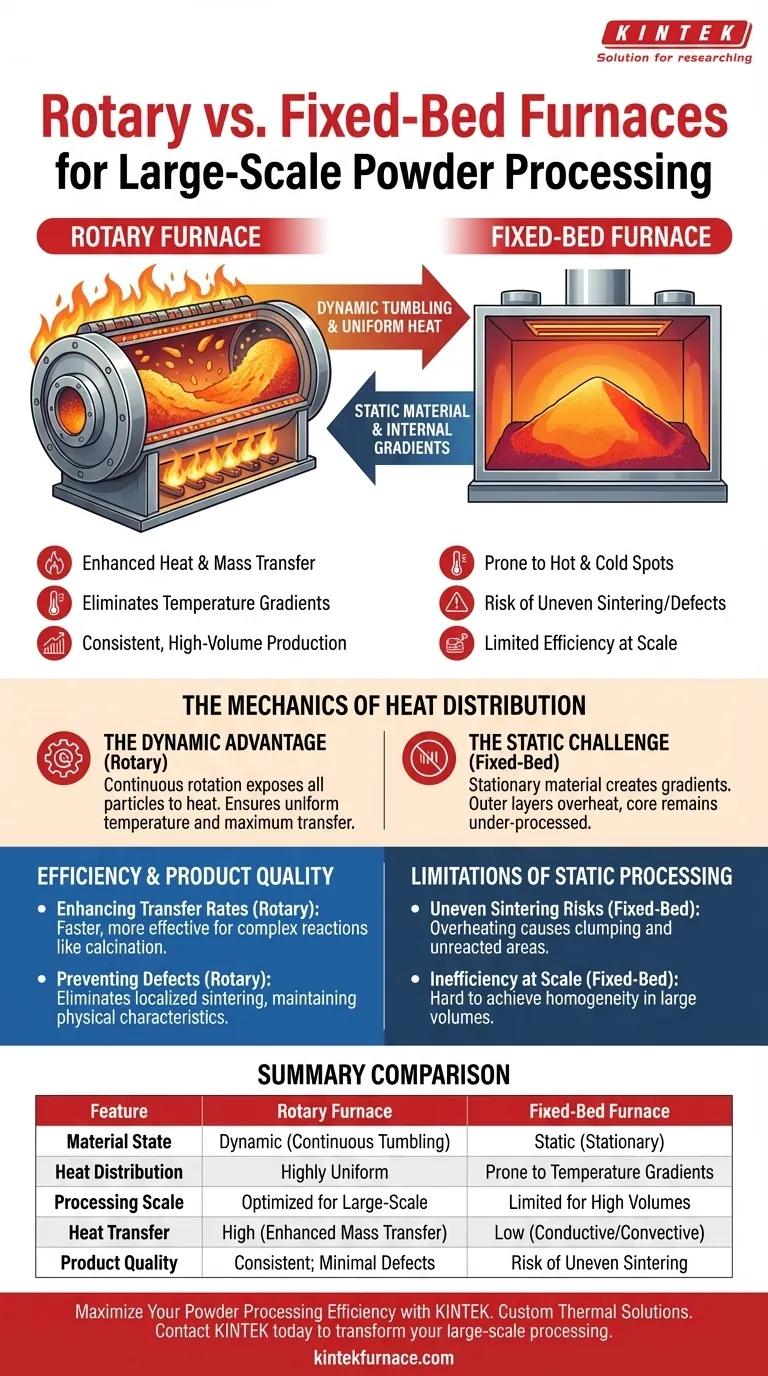

For large-scale powder processing, the rotary furnace is the superior choice over a fixed-bed system. While a fixed-bed furnace keeps materials stationary, a rotary furnace utilizes a continuously rotating tube to tumble the powder. This dynamic motion ensures uniform heat distribution and prevents the processing issues common in static systems.

Static heating methods often lead to uneven results when processing bulk powders. By continuously tumbling material, a rotary furnace eliminates temperature gradients and maximizes heat transfer, making it the standard for consistent, high-volume production.

The Mechanics of Heat Distribution

The Challenge of Static Heating

In a fixed-bed furnace, the raw material remains stationary throughout the process. This lack of movement typically results in internal temperature gradients. The outer layers of the powder may reach the target temperature, while the core remains under-processed.

The Dynamic Advantage

A rotary furnace solves this by continuously rotating the furnace tube. This rotation causes the powder materials to tumble rather than sit still. This constant motion exposes all particles to the heat source evenly, ensuring the entire batch reaches the same temperature.

Efficiency and Product Quality

Enhancing Transfer Rates

The tumbling action does more than just mix the powder; it significantly enhances heat and mass transfer efficiency. This makes the rotary furnace particularly effective for complex processes like calcination, reduction, or surface modification where consistent reaction rates are critical.

preventing Defects

Uniform heating is essential for maintaining product quality. By eliminating hot and cold spots, the rotary furnace prevents localized uneven sintering. This ensures the final powder retains the desired physical characteristics without forming unwanted agglomerates.

The Limitations of Static Processing

Uneven Sintering Risks

When scaling up with a fixed-bed furnace, the risk of product defects increases. Without the dynamic tumbling action, parts of the powder bed may overheat and sinter together while other parts remain unreacted.

Inefficiency at Scale

The primary reference highlights that static methods struggle with large-scale processing. As the volume of powder increases, the inability to mix the material creates substantial barriers to achieving heat homogeneity, making fixed-bed systems less viable for high-volume production.

Making the Right Choice for Your Goal

To select the correct furnace type, you must evaluate your specific processing requirements against the capabilities of the equipment.

- If your primary focus is large-scale uniformity: Choose a rotary furnace to ensure every particle undergoes the exact same thermal history through continuous tumbling.

- If your primary focus is preventing material defects: Rely on the dynamic heating of a rotary furnace to eliminate the temperature gradients that cause uneven sintering.

The rotary furnace transforms powder processing from a static challenge into a dynamic, highly efficient operation.

Summary Table:

| Feature | Rotary Furnace | Fixed-Bed Furnace |

|---|---|---|

| Material State | Dynamic (Continuous Tumbling) | Static (Stationary) |

| Heat Distribution | Highly Uniform | Prone to Temperature Gradients |

| Processing Scale | Optimized for Large-Scale | Limited for High Volumes |

| Heat Transfer | High (Enhanced Mass Transfer) | Low (Conductive/Convective Only) |

| Product Quality | Consistent; Minimal Sintering Defects | Risk of Uneven Sintering/Hot Spots |

Maximize Your Powder Processing Efficiency with KINTEK

Don’t let static heating limitations hinder your production quality. KINTEK provides industry-leading thermal solutions, including high-performance Rotary, Muffle, Tube, Vacuum, and CVD systems. Backed by expert R&D and precision manufacturing, our furnaces are fully customizable to meet the unique demands of your laboratory or industrial facility.

Ready to eliminate temperature gradients and ensure uniform results? Contact KINTEK today to discover how our advanced heating technology can transform your large-scale processing.

Visual Guide

References

- Dimple Dimple, Priyanka Verma. Visible‐NIR Light‐Driven Hydrogen Evolution from Ammonia Borane Using Defect‐Engineered Pd/WO<sub>3‐x</sub> Catalyst. DOI: 10.1002/cctc.202500795

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the function of nitrogen gas flow in a rotary furnace? Master Activation at 1373 K

- Why are rotary tube furnaces suitable for continuous material processing? Achieve Uniform Heating and High Throughput

- What are the key advantages of rotary furnaces compared to other furnace types? Superior Uniformity and Efficiency

- How are rotary tube furnaces used in the calcination of oil shale? Efficiently Convert Kerogen to Hydrocarbons

- What are indirect-fired rotary kilns (calciners) and for which processes are they suitable? Achieve Unmatched Process Purity

- What are the zones inside the rotary kiln cylinder? Unlock Efficient Material Processing

- What processes benefit from rotary furnaces in material sintering? Achieve Uniform Sintering for Powders and Ceramics

- What thermal treatment processes in minerals processing use indirect-fired rotary kilns? Ensure Purity and Control