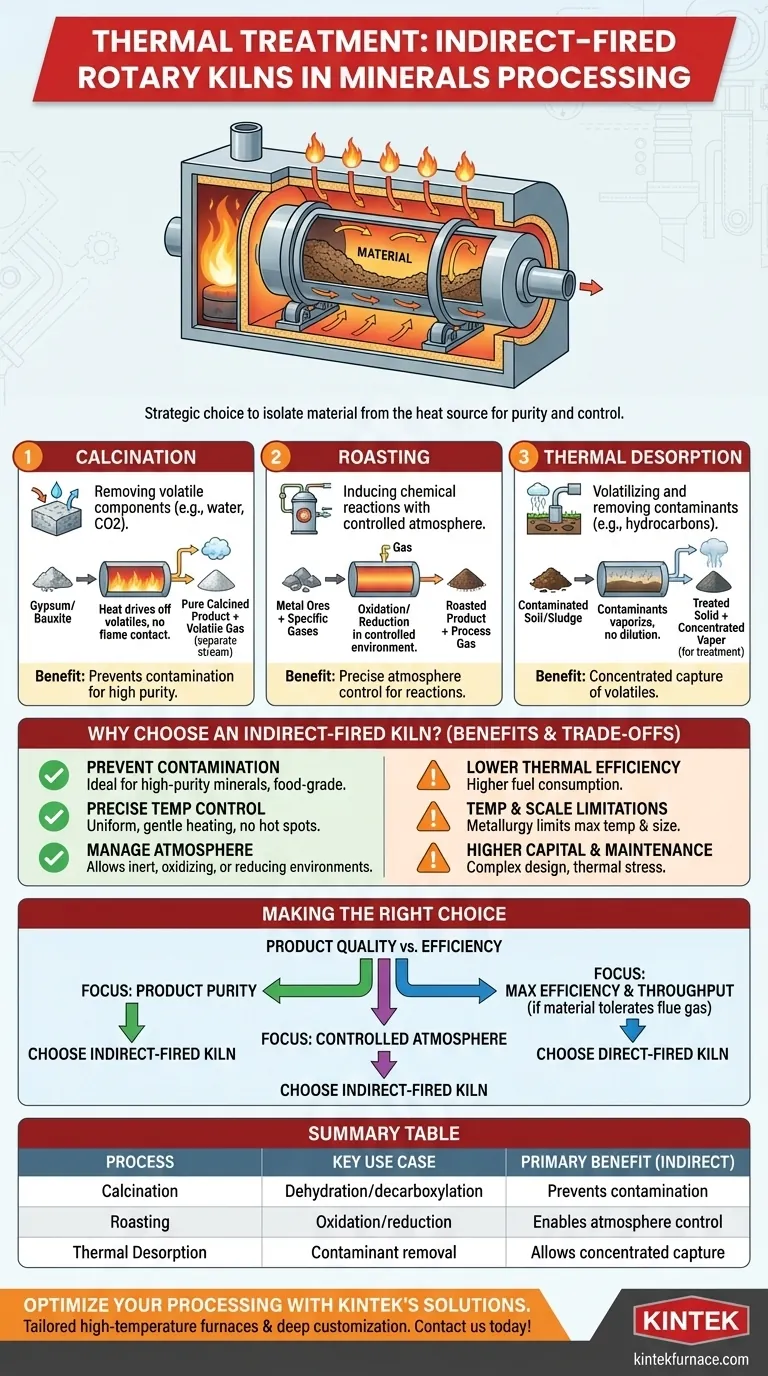

In minerals processing, indirect-fired rotary kilns are specifically chosen for three primary thermal treatments: calcination, roasting, and thermal desorption. These processes are selected when the material being treated is sensitive and cannot be exposed to combustion gases, ensuring product purity and precise process control.

The decision to use an indirect-fired rotary kiln is not just about heating a material; it is a strategic choice to isolate the material from the heat source. This separation is critical when preventing contamination and controlling the processing atmosphere are more important than maximizing thermal efficiency.

Understanding the Core Processes

An indirect-fired kiln works by heating the outside of a rotating drum. The material tumbles inside the drum, absorbing heat through the steel shell without ever coming into contact with the flame or flue gas.

Calcination

Calcination is a process that uses heat to drive off a volatile component from a solid, such as removing chemically bound water (dehydration) or carbon dioxide (decarboxylation).

Using an indirect kiln is vital when the final product's purity is paramount. For example, processing minerals like gypsum or bauxite requires precise temperature to achieve the desired chemical phase without introducing impurities from fuel combustion.

Roasting

Roasting involves heating a solid to induce a specific chemical reaction with the furnace atmosphere, often for oxidation or reduction of metal ores.

Because an indirect-fired kiln keeps combustion gases separate, operators have complete control over the atmosphere inside the kiln. This allows for the introduction of specific gases to drive desired reactions, a level of control impossible in a direct-fired system.

Thermal Desorption

This process uses heat to volatilize and remove contaminants, such as hydrocarbons or organic compounds, from a solid material like soil or industrial sludge.

Indirect heating is essential here because it allows the vaporized contaminants to be drawn off as a concentrated stream. This makes them easier to capture and treat, which would be difficult if they were diluted with a large volume of combustion flue gas.

Why Choose an Indirect-Fired Kiln?

The choice of an indirect kiln is always driven by the specific needs of the material and the desired end-product. The benefits center on control and purity.

To Prevent Material Contamination

This is the primary reason. For high-purity minerals, specialty chemicals, or food-grade products, any contact with sulfur, ash, or other byproducts of combustion could ruin the final product. An indirect kiln eliminates this risk entirely.

To Achieve Precise Temperature Control

Indirect kilns provide highly uniform and gentle heating. Since the heat is transferred through the entire surface of the drum shell, it avoids the intense hot spots that can occur in direct-fired systems, protecting heat-sensitive materials from degradation.

To Manage the Process Atmosphere

Separating the material from the heating environment allows for a fully controlled internal atmosphere. This is critical for processes that require an inert (nitrogen), oxidizing (oxygen-rich), or reducing (hydrogen) environment to achieve a specific chemical transformation.

Understanding the Trade-offs

While powerful, indirect-fired kilns are not a universal solution. Their design introduces specific limitations that must be considered.

Lower Thermal Efficiency

Heating the material through a thick metal shell is inherently less efficient than exposing it directly to a flame. This means indirect kilns typically consume more fuel for a given throughput, leading to higher operational costs.

Temperature and Scale Limitations

The maximum operating temperature of an indirect kiln is limited by the metallurgy of the rotating shell, which must maintain its structural integrity while being heated externally. They are also generally built on a smaller scale than the massive direct-fired kilns used in industries like cement.

Higher Capital and Maintenance Costs

The design, featuring an external furnace and a specialized rotating drum, is more complex and expensive to build. The shell is also subjected to significant thermal stress, which can lead to higher maintenance requirements over the kiln's lifetime.

Making the Right Choice for Your Process

Your decision must balance the need for product quality against operational efficiency.

- If your primary focus is product purity: An indirect-fired kiln is essential to prevent contamination from combustion byproducts.

- If your primary focus is maximum thermal efficiency and high throughput: A direct-fired kiln is often the more economical choice, provided your material can tolerate contact with flue gas.

- If your primary focus is driving specific chemical reactions in a controlled atmosphere: The atmospheric control offered by an indirect-fired kiln is a critical and non-negotiable advantage.

Ultimately, selecting the right kiln technology depends on a clear understanding of your material's chemistry and your final product's quality requirements.

Summary Table:

| Process | Key Use Case | Primary Benefit in Indirect Kiln |

|---|---|---|

| Calcination | Dehydration/decarboxylation of minerals like gypsum | Prevents contamination for high-purity products |

| Roasting | Oxidation/reduction of metal ores | Enables precise atmosphere control for specific reactions |

| Thermal Desorption | Removal of contaminants from soil/sludge | Allows easy capture of volatiles without dilution |

Optimize your minerals processing with KINTEK's tailored high-temperature solutions! Leveraging exceptional R&D and in-house manufacturing, we provide advanced indirect-fired rotary kilns and other furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capabilities ensure precise fit for your unique experimental needs, enhancing purity and efficiency. Contact us today to discuss how we can support your thermal treatment processes!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the primary applications of an electric rotary kiln? Achieve High-Purity Material Processing with Precision

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency

- How does customization benefit the use of rotary kilns? Boost Efficiency and Quality with Tailored Solutions

- What data is necessary to design a rotary kiln? Essential Factors for Efficient Thermal Processing

- What role does gas flow and combustion play in a rotary kiln? Optimize Heat Transfer for Efficiency and Quality