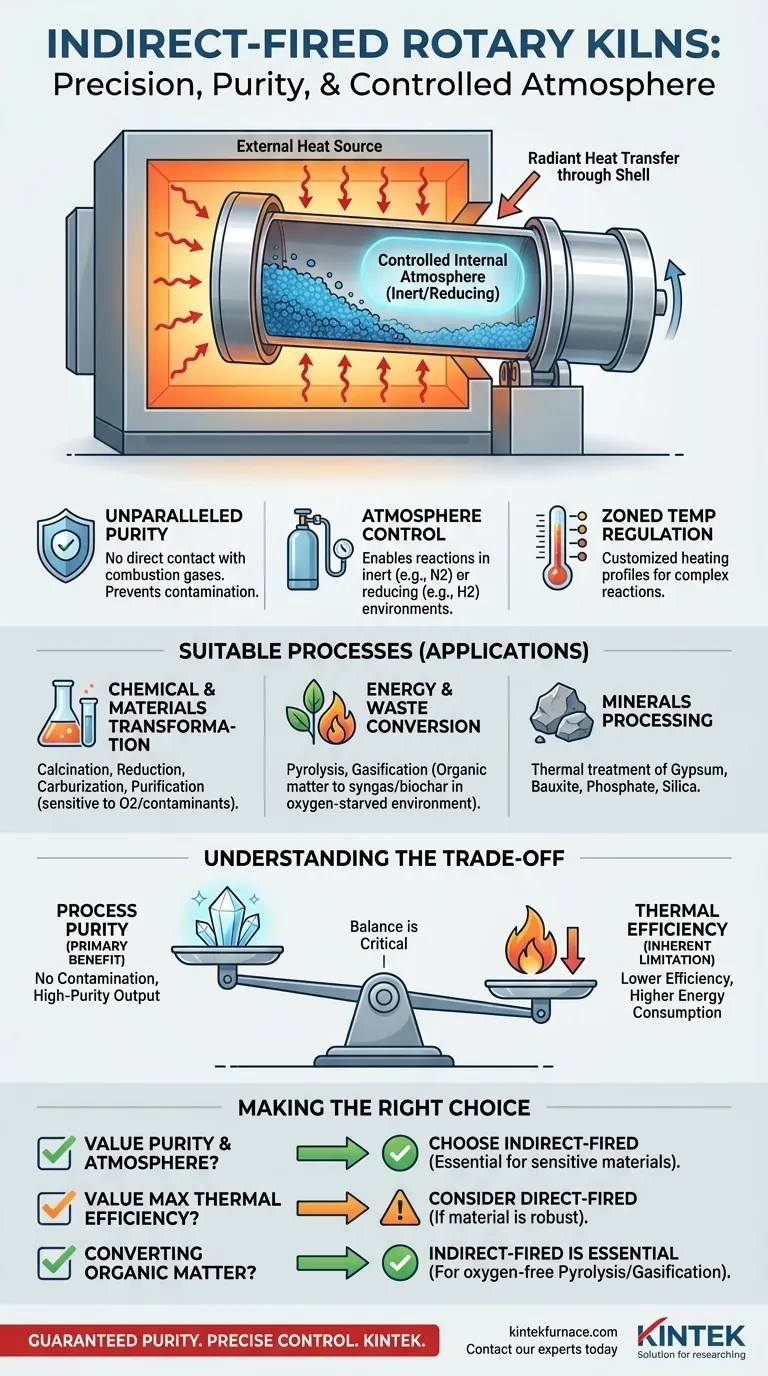

At its core, an indirect-fired rotary kiln is a thermal processing unit that heats material without any direct contact between the material and the combustion gases. It functions by heating the exterior of a rotating drum, allowing radiant heat to transfer through the shell wall to the material tumbling inside. This design provides unparalleled control over the internal atmosphere.

The fundamental advantage of an indirect-fired kiln is its ability to maintain a pure, controlled process atmosphere. This makes it the superior choice for sensitive materials and specific chemical reactions, despite being less thermally efficient than direct-fired alternatives.

How an Indirect-Fired Kiln Achieves Precision Control

The unique design of an indirect-fired kiln, also known as a calciner, is entirely focused on separating the heating source from the process material. This separation is the key to its specialized applications.

The Core Principle: External Heating

The kiln is essentially a rotating tube housed within a larger, stationary furnace or surrounded by heating elements. The heat source warms the outside of the rotating tube, and this energy radiates inward.

As the kiln rotates, it continuously tumbles the material, ensuring uniform exposure to the heated inner surface for consistent and efficient heat transfer.

Creating a Controlled Atmosphere

Because the flames or combustion byproducts never enter the processing chamber, the internal atmosphere can be precisely managed.

This allows for processes to occur in inert (e.g., nitrogen), reducing (e.g., hydrogen), or other specific gaseous environments that would be impossible in a direct-fired system where combustion gases mix with the material.

Zoned Temperature Regulation

Modern indirect kilns often feature multiple, independent heating zones along the length of the drum.

This allows for a highly customized temperature profile, enabling material to be heated, held at a specific temperature, and then cooled according to the exact requirements of a chemical reaction.

Key Applications Driven by Atmosphere Control

The ability to dictate the internal environment makes indirect-fired kilns essential for a range of high-temperature processes where purity and specific reactions are paramount.

Chemical and Materials Transformation

These kilns are ideal for high-temperature reactions that are sensitive to oxygen or other contaminants.

Key processes include calcination, reduction of metal ores, carburization, and the purification of various materials where a specific chemical transformation is required.

Energy and Waste Conversion

Indirect heating is critical for processes like pyrolysis and gasification.

In these applications, organic materials like biomass or waste are thermally decomposed in an oxygen-starved environment to produce valuable outputs like syngas or biochar, rather than simply being incinerated.

Minerals Processing

Industries use indirect kilns for the thermal treatment of minerals such as gypsum, bauxite, phosphate ore, and silica sand.

The controlled heating achieves specific chemical and physical changes in the minerals without introducing impurities from combustion flue gas.

Understanding the Trade-offs

Choosing an indirect-fired kiln involves a clear trade-off between process control and operational efficiency. Understanding this balance is critical for making an informed decision.

The Primary Benefit: Process Purity

The definitive advantage is preventing contamination. The material being processed only comes into contact with the kiln shell and the controlled atmosphere you introduce, ensuring a pure final product.

The Inherent Limitation: Thermal Efficiency

Heating a material through a thick metal shell is inherently less efficient than heating it with a direct flame. This means indirect-fired kilns generally consume more energy per unit of material processed compared to their direct-fired counterparts.

Material and Temperature Constraints

The maximum operating temperature of the kiln is limited by the metallurgy of the rotating drum itself. The shell must withstand the external heating while maintaining structural integrity at high temperatures, which can be a design constraint for ultra-high-temperature applications.

Making the Right Choice for Your Process

Your specific process goals will determine whether an indirect-fired kiln is the correct technology for your needs.

- If your primary focus is process purity and atmosphere control: An indirect-fired kiln is the essential choice for sensitive reactions or when producing high-purity materials that cannot be contaminated by combustion gases.

- If your primary focus is maximum thermal efficiency and bulk processing: A direct-fired kiln is likely more cost-effective, assuming your material is robust and not negatively affected by direct contact with flue gas.

- If you are converting organic matter into fuel or biochar: The oxygen-free environment of an indirect-fired kiln is non-negotiable for enabling pyrolysis or gasification instead of combustion.

Ultimately, selecting the right kiln technology comes down to understanding whether your process values atmospheric control more than raw thermal efficiency.

Summary Table:

| Feature | Advantage | Ideal For |

|---|---|---|

| External Heating | No contamination from combustion gases | High-purity materials, sensitive chemical reactions |

| Controlled Atmosphere | Operate in inert or reducing environments | Pyrolysis, gasification, metal reduction |

| Zoned Temperature Control | Precise heating profiles for complex reactions | Calcination, minerals processing, purification |

Need a thermal processing solution that guarantees purity and precise atmosphere control?

At KINTEK, we specialize in advanced thermal processing equipment. Our expertise in designing and manufacturing robust systems ensures your sensitive materials are processed in the exact environment they require—whether inert, reducing, or specialized atmospheres for calcination, pyrolysis, or purification.

Let's discuss your application. Contact our experts today to explore how a custom indirect-fired kiln can optimize your process and product quality.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What supporting equipment is needed for a rotary kiln system? Essential Components for Efficient Thermal Processing

- What data is necessary to design a rotary kiln? Essential Factors for Efficient Thermal Processing

- What are the primary applications of an electric rotary kiln? Achieve High-Purity Material Processing with Precision

- How does customization benefit the use of rotary kilns? Boost Efficiency and Quality with Tailored Solutions

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency