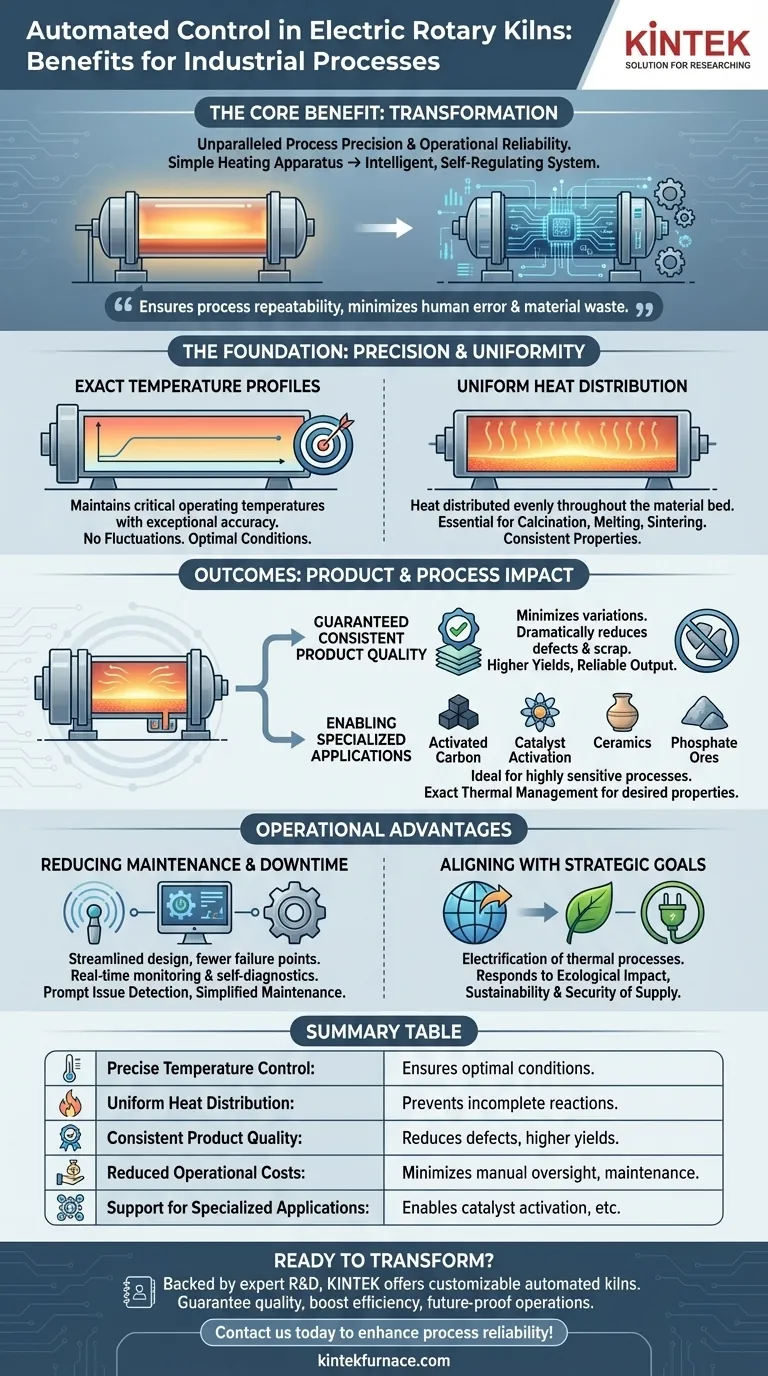

In short, automated control in electric rotary kilns delivers unparalleled process precision and operational reliability. This automation ensures exact temperature management and uniform heating, which directly translates into higher, more consistent product quality, reduced operational costs, and the ability to meet the demanding requirements of specialized industrial applications.

The core benefit is transformation: automated control elevates an electric rotary kiln from a simple heating apparatus to an intelligent, self-regulating system that guarantees process repeatability and minimizes the risk of human error and material waste.

The Foundation of Control: Precision and Uniformity

The primary advantage of any automated system is its ability to execute parameters with a precision that manual oversight cannot match. In thermal processing, this precision is the foundation for every subsequent benefit.

Achieving Exact Temperature Profiles

Automated control systems maintain operating temperatures with exceptional accuracy. This is critical for materials with narrow pre-firing or reaction temperature windows.

By eliminating temperature fluctuations, the system ensures the material is processed under optimal conditions from start to finish.

Ensuring Uniform Heat Distribution

Beyond holding a specific temperature, automation ensures that heat is distributed evenly throughout the material bed.

This uniformity is essential for processes like calcination, melting, and sintering, where inconsistent heating can lead to incomplete reactions and substandard product properties.

The Impact on Product and Process Outcomes

Precise control is not just a technical feature; it has a direct and significant impact on the quality of the end product and the efficiency of the entire operation.

Guaranteeing Consistent Product Quality

The most significant outcome of automated control is consistent, repeatable product quality.

By minimizing temperature variations and ensuring uniform processing, automation dramatically reduces the rate of product defects and material scrap. This leads to higher yields and more reliable output.

Enabling Specialized Applications

This level of control makes electric rotary kilns ideal for highly sensitive industrial processes.

Applications like the production of activated carbon, catalyst activation, ceramics processing, and the upgrading of phosphate ores all rely on exact thermal management to achieve their desired chemical and physical properties.

Understanding the Operational Advantages

Beyond product quality, automation fundamentally improves the day-to-day operation of the kiln, leading to greater efficiency, safety, and lower long-term costs.

Reducing Maintenance and Downtime

Modern electric kilns, particularly electromagnetic induction models, feature a streamlined design with fewer mechanical failure points.

When paired with advanced sensors and control systems, the kiln can perform real-time monitoring and self-diagnostics. This intelligent approach allows for prompt issue detection, simplifying maintenance and enhancing overall reliability.

Aligning with Strategic Industrial Goals

The push for automation is also driven by broader industry trends. Historically, process selection was based purely on economics.

Today, factors like ecological impact and security of supply are major considerations. The electrification of thermal processes, managed by sophisticated automation, is a direct response to these modern industrial demands.

How to Apply This to Your Project

Your decision to leverage an automated electric rotary kiln should be guided by your primary operational goal.

- If your primary focus is uncompromising product quality: The precise temperature control of an automated system is essential, especially for materials sensitive to thermal variations.

- If your primary focus is operational efficiency: Automation delivers a clear return by minimizing defects, reducing the need for manual oversight, and lowering long-term maintenance costs.

- If your primary focus is future-proofing your operations: Adopting automated electric kilns aligns your process with the industry-wide move toward electrification, sustainability, and enhanced supply chain security.

Ultimately, implementing automated control is the definitive step toward unlocking the full potential of high-performance thermal processing.

Summary Table:

| Key Benefit | Impact on Industrial Process |

|---|---|

| Precise Temperature Control | Ensures optimal processing conditions, critical for sensitive materials. |

| Uniform Heat Distribution | Prevents incomplete reactions and guarantees consistent product properties. |

| Consistent Product Quality | Reduces defects and material scrap, leading to higher yields. |

| Reduced Operational Costs | Minimizes manual oversight, maintenance, and downtime. |

| Support for Specialized Applications | Enables processes like catalyst activation and ceramics sintering. |

Ready to transform your thermal processing with precision automation?

Backed by expert R&D and manufacturing, KINTEK offers advanced electric rotary kilns with sophisticated automated control systems. Whether you need to guarantee product quality, boost operational efficiency, or future-proof your operations, our solutions are customizable for your unique industrial needs.

Contact us today to discuss how our automated kilns can enhance your process reliability and deliver consistent, high-quality results!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is a Rotary Kiln specifically suitable for treating high-carbon FMDS? Turn Waste Carbon into a Resource

- What are the uses of rotary kilns in the building materials industry besides cement clinker? Key Applications Explained

- What are some drying applications of electromagnetic rotary kilns? Discover Efficient, Precise Drying Solutions

- What is the basic working principle of a rotary kiln? Master Industrial Thermal Processing Efficiency

- How is bed depth controlled in a rotary kiln and why is it important? Optimize Heat Transfer and Efficiency