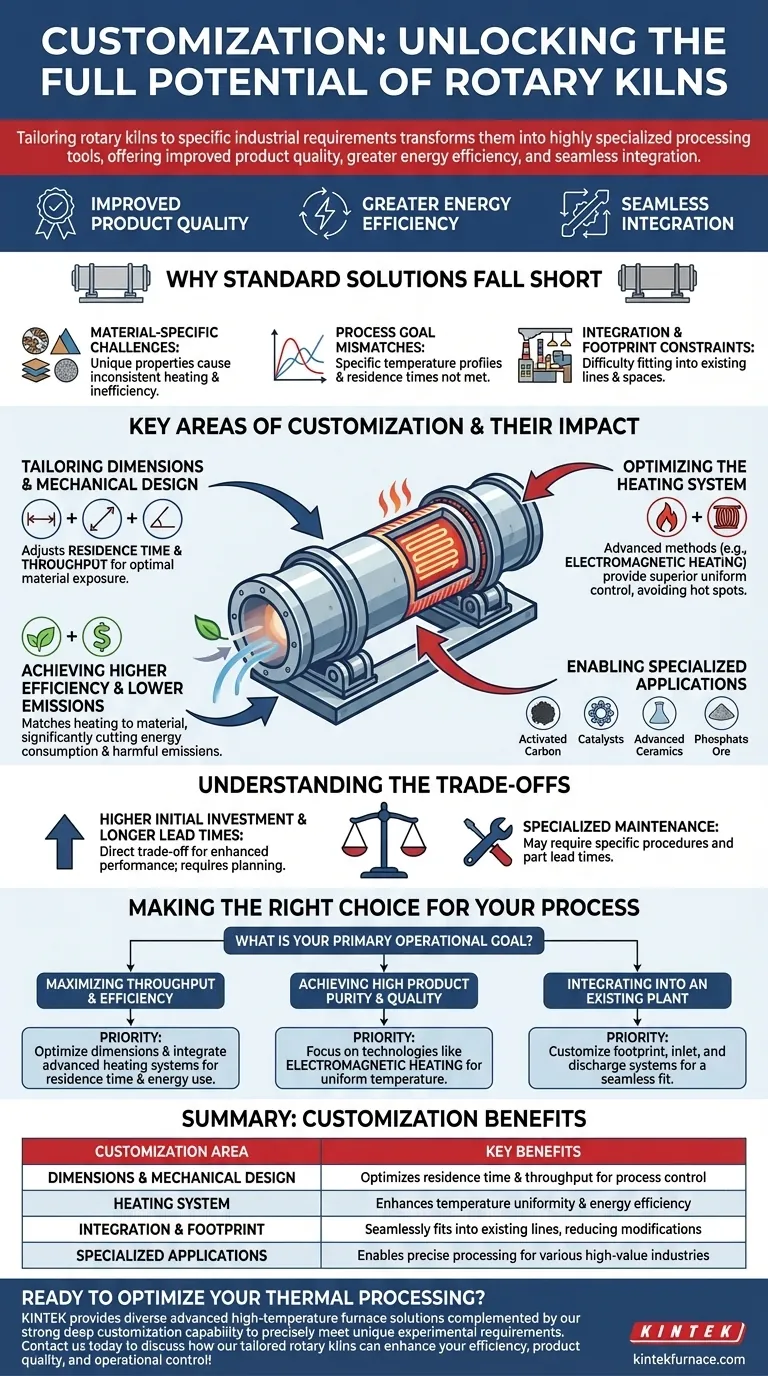

Customizing a rotary kiln transforms it from a generic piece of equipment into a highly specialized processing tool. This tailoring allows the kiln to meet specific industrial requirements, from handling unique materials to achieving precise thermal outcomes. The primary benefits are improved product quality, greater energy efficiency, and seamless integration into existing production lines.

The true value of rotary kiln customization lies in moving beyond a one-size-fits-all approach. By tailoring the kiln's design, dimensions, and heating method to your specific material and process goals, you unlock significant gains in efficiency, product quality, and operational control.

Why Standard Solutions Often Fall Short

A generic, off-the-shelf rotary kiln is designed for a broad range of applications but is rarely optimized for any single one. This can lead to significant inefficiencies when dealing with specific industrial processes.

Material-Specific Challenges

Different materials have unique densities, particle sizes, flow characteristics, and thermal properties. A standard kiln may cause inconsistent heating, material degradation, or inefficient processing if not designed to handle the specific characteristics of your feedstock.

Process Goal Mismatches

The thermal requirements for drying, calcination, pyrolysis, or chemical reaction are vastly different. Each process demands a specific temperature profile, residence time, and atmospheric condition that a standard kiln cannot precisely deliver.

Integration and Footprint Constraints

An existing production facility has fixed space and established upstream and downstream equipment. A customized kiln can be designed to fit a specific footprint and integrate perfectly with your current material handling systems, avoiding costly plant modifications.

Key Areas of Customization and Their Impact

Customization allows engineers to optimize every aspect of the kiln's performance for a single, well-defined purpose. This targeted design directly translates to better operational outcomes.

Tailoring Dimensions and Mechanical Design

The length, diameter, and inclination angle of the kiln shell are fundamental variables. These are adjusted to control the residence time—how long the material stays in the kiln—and the total throughput, ensuring the material is exposed to heat for the optimal duration.

Optimizing the Heating System

The method of heat delivery is critical. While traditional direct or indirect-fired systems are common, advanced methods offer superior control.

Electromagnetic heating, for instance, provides exceptional temperature uniformity and precision. This avoids the temperature fluctuations and hot spots common in other systems, leading to a higher quality, more consistent final product.

Achieving Higher Efficiency and Lower Emissions

By matching the heating system to the material's properties, you reduce wasted energy. Advanced systems like electromagnetic heating can significantly cut down on energy consumption and the associated harmful emissions, improving both environmental and financial performance.

Enabling Specialized Applications

Customization is what makes rotary kilns viable for highly specialized, high-value industries.

Examples include:

- Activated Carbon: Production and reactivation require precise temperature control in a controlled atmosphere to create the desired porous structure for purification.

- Catalyst Activation: Specific temperature ramps and hold times are necessary to activate catalysts without damaging them.

- Advanced Ceramics & Plastics: These materials demand extremely uniform heating to prevent stress fractures and ensure consistent properties.

- Phosphate Ore Upgrading: Custom kilns are designed to remove impurities from phosphate rock, increasing its P2O5 content for agricultural use.

Understanding the Trade-offs

While the benefits are clear, choosing a custom solution involves important considerations. Acknowledging these trade-offs is key to making a sound investment decision.

Higher Initial Investment

A bespoke rotary kiln designed and built for a specific purpose will have a higher upfront cost than a standard, mass-produced model. This is a direct trade-off for its enhanced performance and efficiency.

Longer Lead Times

The process of consultation, design, engineering, and fabrication for a custom unit is more time-intensive. Your project timeline must account for this extended development cycle.

Specialized Maintenance

Custom components may require specialized maintenance procedures or have longer lead times for replacement parts compared to standard equipment. This necessitates a clear maintenance plan and a good relationship with the manufacturer.

Making the Right Choice for Your Process

The decision to invest in a custom rotary kiln should be driven by a clear understanding of your primary operational goal.

- If your primary focus is maximizing throughput and efficiency: Prioritize customizing the kiln's dimensions (length/diameter) and integrating an advanced heating system to optimize residence time and energy use.

- If your primary focus is achieving high product purity and quality: Focus on technologies that deliver precise temperature control and uniform heat distribution, such as electromagnetic heating.

- If your primary focus is integrating into an existing plant: Customization of the kiln's footprint, inlet, and discharge systems is non-negotiable to ensure a seamless fit with your current production line.

Ultimately, a well-specified custom rotary kiln is an investment in process control, ensuring your thermal processing goals are met with precision and reliability.

Summary Table:

| Customization Area | Key Benefits |

|---|---|

| Dimensions & Mechanical Design | Optimizes residence time and throughput for better process control |

| Heating System | Enhances temperature uniformity and energy efficiency |

| Integration & Footprint | Seamlessly fits into existing production lines, reducing modifications |

| Specialized Applications | Enables precise processing for industries like activated carbon and ceramics |

Ready to optimize your thermal processing? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our tailored rotary kilns can enhance your efficiency, product quality, and operational control!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- What distinguishes direct from indirect rotary kilns? Choose the Right Kiln for Your Material

- What supporting equipment is needed for a rotary kiln system? Essential Components for Efficient Thermal Processing

- What are the primary applications of an electric rotary kiln? Achieve High-Purity Material Processing with Precision

- What data is necessary to design a rotary kiln? Essential Factors for Efficient Thermal Processing

- How do vibrational feeder specifications impact rotary kiln efficiency? Optimize Your Lab's Material Flow & Stability