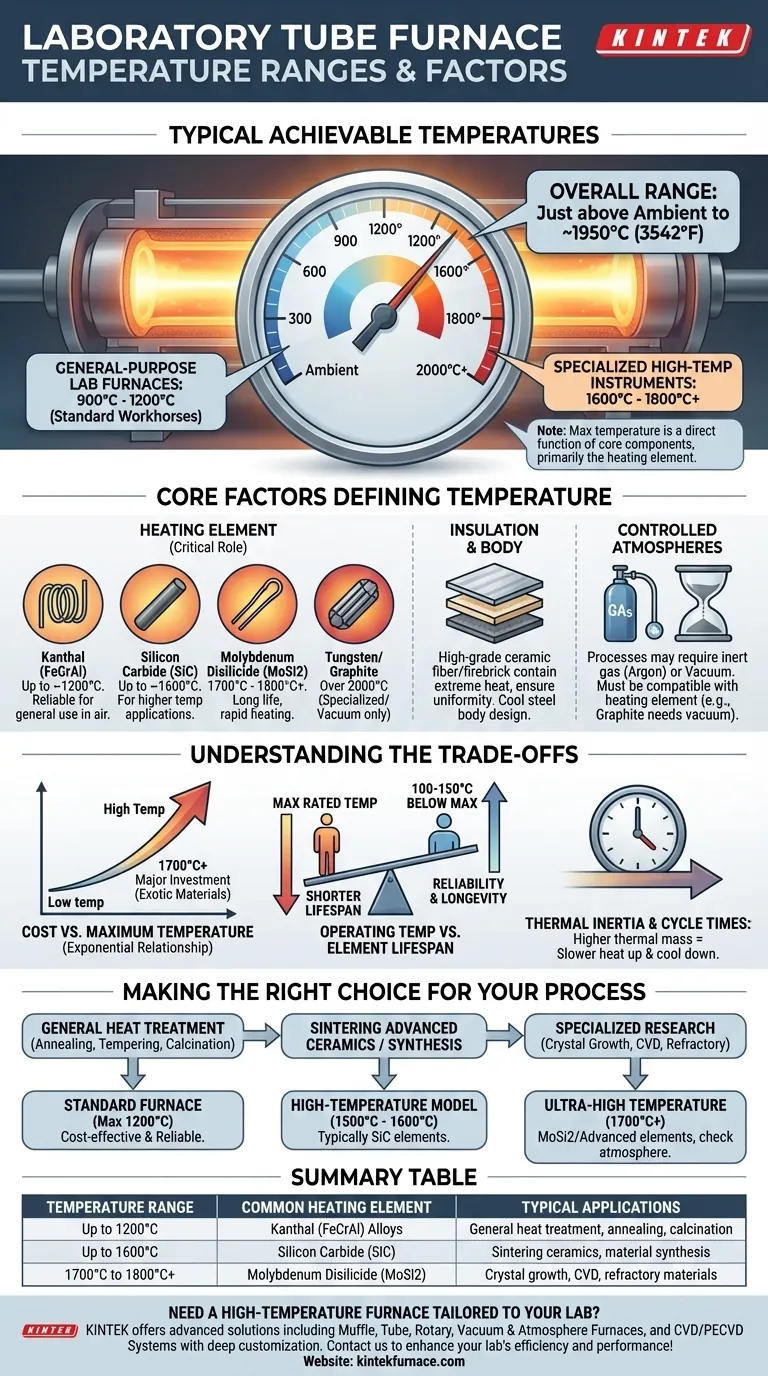

In short, a laboratory tube furnace can operate at temperatures ranging from just above ambient to as high as 1950°C (3542°F). However, the vast majority of general-purpose lab furnaces operate in a much narrower range, typically with maximum temperatures between 900°C and 1200°C. Models capable of reaching 1600°C, 1800°C, or higher are specialized instruments designed for specific high-temperature applications.

The maximum achievable temperature of a tube furnace is not a single standard, but a direct function of its core components—primarily the heating element material. Understanding this relationship is the key to selecting the right furnace for your specific thermal process.

The Core Factors Defining Temperature Range

A furnace's temperature rating is not an arbitrary number. It is a hard limit dictated by the physical properties of the materials used in its construction.

The Critical Role of the Heating Element

The single most important factor is the material used for the heating element. Different materials have different maximum operating temperatures before they degrade or fail.

- Kanthal (FeCrAl) Alloys: These are the workhorses for standard furnaces, reliably operating up to ~1200°C. They are cost-effective and robust for general use in air.

- Silicon Carbide (SiC): For higher temperature applications, SiC elements are used. These can operate continuously at temperatures up to ~1600°C.

- Molybdenum Disilicide (MoSi2): When you need to exceed 1600°C, MoSi2 elements are the standard choice. They can reach temperatures of 1700°C to 1800°C and are known for their long life and rapid heating capabilities.

- Specialized Elements (Tungsten/Graphite): For the most extreme applications like certain Chemical Vapor Deposition (CVD) processes, elements like tungsten or graphite can be used to reach over 2000°C. These almost always require a vacuum or controlled inert atmosphere to prevent immediate oxidation and failure.

Furnace Insulation and Body

The furnace's performance also depends on its insulation. High-grade ceramic fiber or firebrick is necessary to contain the extreme heat, ensure temperature uniformity, and maintain efficiency. The furnace's steel body and casing must be designed to remain cool and structurally sound.

Controlled Atmospheres

The environment inside the tube also plays a part. While many processes run in air, some require an inert gas (like Argon) or a vacuum. The choice of heating element must be compatible with the desired atmosphere, as some elements (like graphite) will burn up instantly in the presence of oxygen at high temperatures.

Understanding the Trade-offs

Choosing a furnace is a balance of capability, longevity, and cost. Higher temperatures introduce significant engineering challenges and expenses.

Cost vs. Maximum Temperature

The relationship between cost and maximum temperature is exponential. A 1200°C furnace is a standard piece of equipment, but a 1700°C furnace is a major investment due to the exotic materials required for its elements and insulation.

Operating Temperature vs. Element Lifespan

Consistently running a furnace at its absolute maximum rated temperature will drastically shorten the life of its heating elements. A critical best practice is to choose a furnace with a maximum temperature at least 100-150°C higher than your intended, routine operating temperature. This ensures reliability and longevity.

Thermal Inertia and Cycle Times

Furnaces with more robust insulation and heavier elements required for higher temperatures often have more thermal mass. This means they may heat up and, more importantly, cool down more slowly than lower-temperature models.

Making the Right Choice for Your Process

Your specific application dictates the furnace you need. The goal is to meet your process requirements without over-investing in unnecessary temperature capabilities.

- If your primary focus is general heat treatment like annealing, tempering, or calcination: A standard furnace with a maximum temperature of 1200°C is typically the most cost-effective and reliable choice.

- If your primary focus is sintering advanced ceramics or certain material syntheses: You will likely require a high-temperature model capable of reaching 1500°C to 1600°C, typically using SiC elements.

- If your primary focus is specialized research like crystal growth, advanced CVD, or processing refractory materials: You must select an ultra-high temperature furnace (1700°C+) with MoSi2 or other advanced elements, paying close attention to its atmospheric capabilities.

Ultimately, selecting the correct furnace is about defining your required operating temperature and choosing a model that comfortably exceeds it.

Summary Table:

| Temperature Range | Common Heating Element | Typical Applications |

|---|---|---|

| Up to 1200°C | Kanthal (FeCrAl) Alloys | General heat treatment, annealing, calcination |

| Up to 1600°C | Silicon Carbide (SiC) | Sintering ceramics, material synthesis |

| 1700°C to 1800°C+ | Molybdenum Disilicide (MoSi2) | Crystal growth, CVD, refractory materials |

Need a high-temperature furnace tailored to your lab's unique needs? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we ensure precise fit for your experimental requirements—whether for general heat treatment or specialized high-temperature processes. Contact us today to discuss how we can enhance your laboratory's efficiency and performance!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency