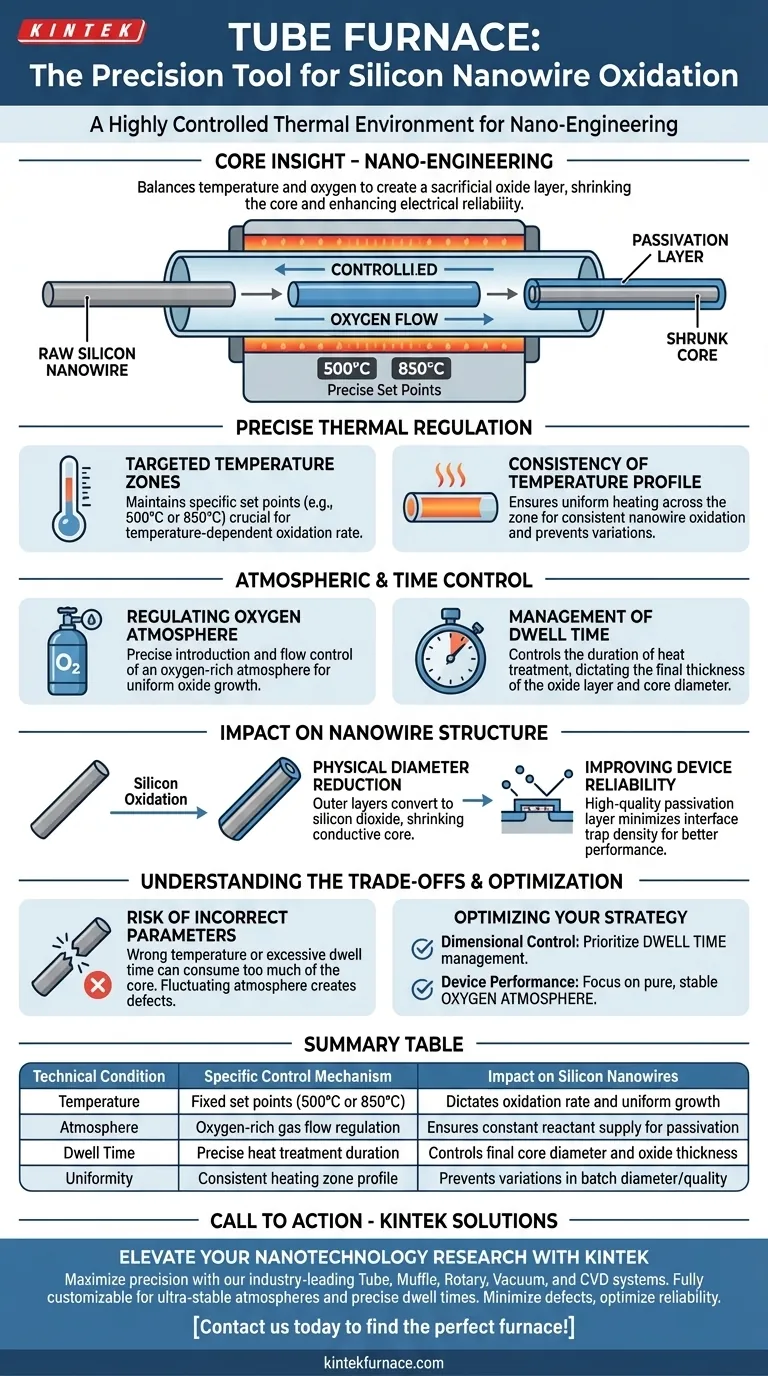

A Tube Furnace provides a highly controlled thermal environment specifically tuned for the delicate oxidation of silicon nanowires. It typically operates at precise temperatures, such as 500°C or 850°C, while strictly regulating the oxygen atmosphere and heat treatment duration to grow high-quality oxide layers.

Core Insight: The tube furnace is not merely a heat source; it is a precision tool for structural nano-engineering. By balancing temperature and oxygen flow, it creates a sacrificial oxide or passivation layer that physically shrinks the nanowire core and enhances electrical reliability by minimizing interface defects.

Precise Thermal Regulation

Targeted Temperature Zones

For silicon nanowire oxidation, the furnace does not simply apply heat; it maintains specific set points, most notably 500°C or 850°C.

Achieving these exact temperatures is critical because the oxidation rate of silicon is highly temperature-dependent.

Consistency of the Temperature Profile

Beyond hitting a maximum temperature, the furnace must ensure a consistent temperature profile across the heating zone.

Uniform heating ensures that all nanowires in the batch undergo the same rate of oxidation, preventing variations in diameter or oxide thickness.

Atmospheric and Time Control

Regulating the Oxygen Atmosphere

The furnace allows for the precise introduction and control of an oxygen-rich atmosphere.

By managing the atmosphere flow rate, you ensure a constant supply of reactant gas to the silicon surface, which is essential for uniform oxide growth.

Management of Dwell Time

The duration of the heat treatment, often referred to as dwell time, is just as critical as the temperature.

The tube furnace allows you to control exactly how long the nanowires remain at the target temperature, effectively dictating the final thickness of the oxide layer.

The Impact on Nanowire Structure

Physical Diameter Reduction

One of the primary goals of this process is reducing the physical diameter of the nanowire core.

As the silicon oxidizes, the outer layers are converted to silicon dioxide, effectively shrinking the conductive silicon core beneath.

Improving Device Reliability

The controlled environment allows for the growth of a high-quality passivation layer.

This layer is crucial for minimizing interface trap density, which reduces electron scattering and significantly improves the reliability and performance of the final device.

Understanding the Trade-offs

The Risk of Incorrect Parameters

While the furnace provides the capability for control, selecting the wrong temperature (e.g., deviating from the optimal 500°C/850°C points) can lead to uncontrolled oxidation.

If the temperature is too high or the dwell time too long, you risk consuming too much of the silicon core, potentially destroying the nanowire's conductive properties.

Atmosphere Stability

The quality of the oxide layer is directly tied to the purity and flow consistency of the gas atmosphere.

Fluctuations in the gas flow rate can lead to uneven passivation, creating defects that trap charges and degrade device performance despite correct thermal settings.

Optimizing Your Oxidation Strategy

To achieve the best results with your silicon nanowires, tailor your furnace settings to your specific engineering limitations:

- If your primary focus is Dimensional Control: Prioritize precise management of dwell time to stop oxidation exactly when the core reaches the desired diameter.

- If your primary focus is Device Performance: Focus on maintaining a pure, stable oxygen atmosphere to minimize interface trap density and ensure a high-quality passivation layer.

The effective use of a Tube Furnace lies in the synchronization of temperature, time, and atmosphere to engineer the nanowire at the atomic level.

Summary Table:

| Technical Condition | Specific Control Mechanism | Impact on Silicon Nanowires |

|---|---|---|

| Temperature | Fixed set points (500°C or 850°C) | Dictates oxidation rate and uniform growth |

| Atmosphere | Oxygen-rich gas flow regulation | Ensures constant reactant supply for passivation |

| Dwell Time | Precise heat treatment duration | Controls final core diameter and oxide thickness |

| Uniformity | Consistent heating zone profile | Prevents variations in batch diameter/quality |

Elevate Your Nanotechnology Research with KINTEK

Maximize the precision of your silicon nanowire fabrication with KINTEK’s industry-leading thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique laboratory requirements.

Whether you need ultra-stable oxygen atmospheres or precise dwell time management, our systems are designed to minimize interface defects and optimize device reliability. Contact us today to find the perfect furnace for your application!

Visual Guide

References

- Lei Wu, Linwei Yu. Step-necking growth of silicon nanowire channels for high performance field effect transistors. DOI: 10.1038/s41467-025-56376-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the primary purpose of using a tube reduction furnace? Achieve High-Purity Fe-Cu Sintering

- What is the function of quartz tube vacuum sealing in Fe3GaTe2 crystal growth? Achieve High-Purity Results

- Why is controlling the residence time within a tube furnace critical for the synthesis of amorphous NiFe2O4 catalysts?

- What role does a tube furnace play in the high-temperature modification of La-EPS-C-450? Key Synthesis Insights

- What are the technical advantages of using a vacuum tube furnace for S53P4-NO2 glass? Achieve 100% Amorphous Results

- How are rotary tube furnaces applied in the chemical industry? Unlock Efficient Thermal Processing

- What are the primary functions of a high-precision tube resistance furnace? Optimize Chloride-Doped Composite Synthesis

- How does the placement of materials within an atmospheric tube furnace affect the yield and purity of LiFePO4?