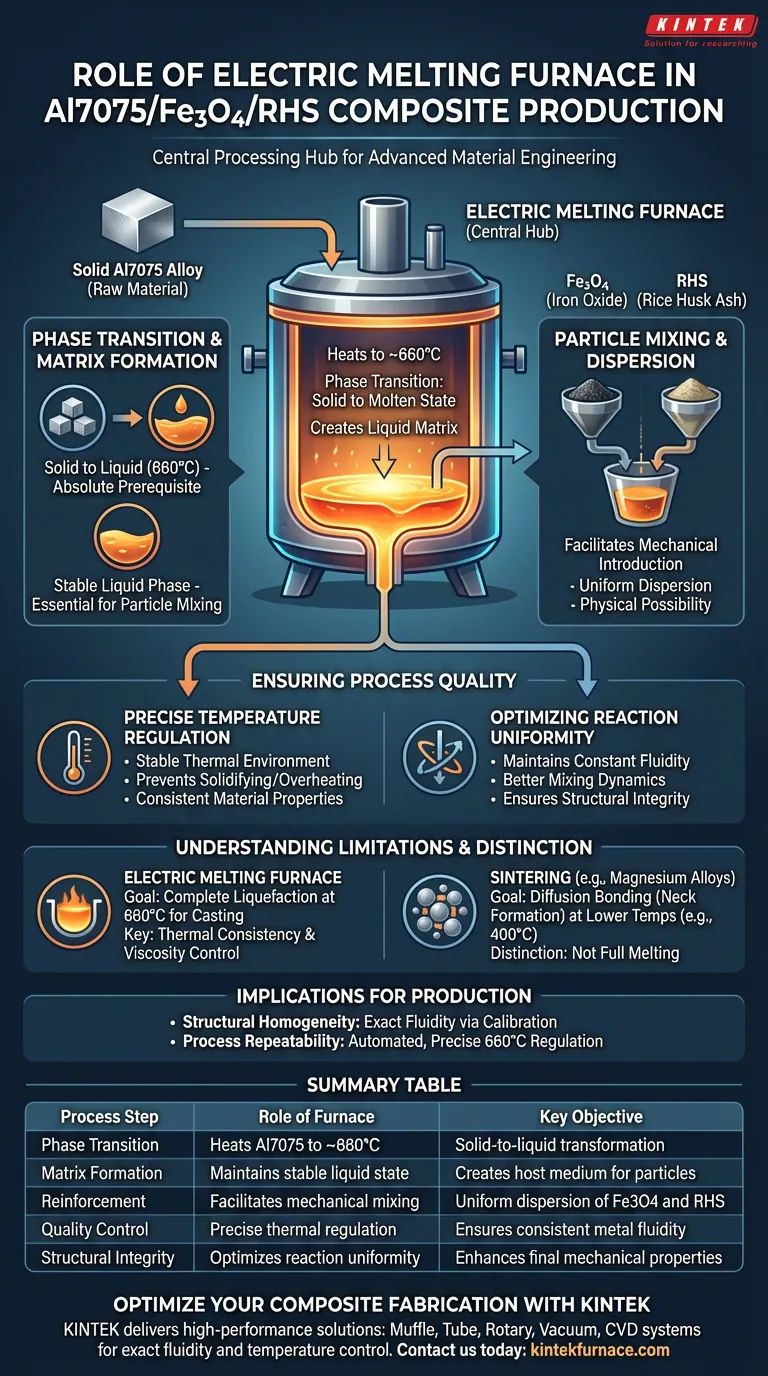

The electric melting furnace functions as the central processing hub in the fabrication of Al7075/Fe3O4/RHS composites. Its primary responsibility is to generate a precisely controlled high-temperature environment that heats the Al7075 alloy to approximately 660 degrees Celsius. This thermal energy transitions the alloy from a solid to a molten state, creating the essential liquid matrix required for introducing reinforcement particles.

Core Insight: The furnace is not simply a heating element; it is the critical stabilization tool that ensures the Aluminum matrix maintains consistent fluidity. Without this controlled phase change, the uniform integration of Fe3O4 and Rice Husk Ash (RHS) would be physically impossible.

Establishing the Composite Matrix

The Solid-to-Liquid Transition

The fundamental role of the furnace is to drive the phase change of the base material.

It heats the Al7075 alloy to its specific melting point of approximately 660 degrees Celsius.

This liquefaction is the absolute prerequisite for the entire production line, converting the solid metal blocks into a workable medium.

Facilitating Particle Mixing

Once the aluminum is molten, the furnace maintains the liquid state necessary for composite formation.

This liquid state allows for the mechanical introduction of Fe3O4 (iron oxide) and RHS (Rice Husk Ash).

Without a stable liquid phase, these external particles cannot be dispersed into the matrix to create the final composite material.

Ensuring Process Quality

Precise Temperature Regulation

The electric melting furnace is designed to provide a highly stable thermal environment.

It prevents temperature fluctuations that could lead to localized solidifying or overheating.

Stable temperature control is vital to ensuring the material properties remain consistent throughout the batch.

Optimizing Reaction Uniformity

By maintaining a constant temperature, the furnace ensures consistent metal fluidity.

Reliable fluidity allows for better mixing dynamics, which leads to higher reaction uniformity between the aluminum matrix and the added particles.

This uniformity is directly linked to the structural integrity of the final cast product.

Understanding the Limitations

Distinction from Sintering Processes

It is critical to distinguish this melting process from other heating methods, such as vacuum sintering used for magnesium alloys.

While other furnaces might operate at lower temperatures (e.g., 400°C) to bond solid particles via diffusion, the electric melting furnace in this context has a different goal.

Its purpose is complete liquefaction at 660°C for casting, not the diffusion bonding or "neck formation" seen in powder metallurgy.

Dependency on Thermal Consistency

The quality of the final composite is entirely dependent on the furnace's ability to hold the specific 660°C target.

Any deviation in the furnace's control mechanisms can alter the viscosity of the melt.

Inconsistent viscosity leads to poor particle distribution, compromising the mechanical performance of the Al7075/Fe3O4/RHS composite.

Implications for Production

To maximize the quality of your composite material, consider the following based on your specific goals:

- If your primary focus is Structural Homogeneity: Ensure your furnace calibration is exact to maintain steady fluidity, which is the key driver for uniform particle dispersion.

- If your primary focus is Process Repeatability: Prioritize equipment that offers automated, precise thermal regulation to keep the alloy at exactly 660°C across multiple batches.

The electric melting furnace effectively unlocks the Al7075 alloy, transforming it from a raw solid into a receptive liquid host for advanced composite engineering.

Summary Table:

| Process Step | Role of Electric Melting Furnace | Key Objective |

|---|---|---|

| Phase Transition | Heats Al7075 alloy to ~660°C | Solid-to-liquid transformation |

| Matrix Formation | Maintains stable liquid state | Creates host medium for particles |

| Reinforcement | Facilitates mechanical mixing | Uniform dispersion of Fe3O4 and RHS |

| Quality Control | Precise thermal regulation | Ensures consistent metal fluidity |

| Structural Integrity | Optimizes reaction uniformity | Enhances final mechanical properties |

Optimize Your Composite Fabrication with KINTEK

Achieving perfect structural homogeneity in Al7075 composites requires the uncompromising thermal precision that only expert-engineered equipment can provide. KINTEK delivers high-performance laboratory solutions—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all designed to maintain the exact fluidity and temperature control your research demands.

Whether you are developing advanced metal-matrix composites or specialized alloys, our customizable high-temperature furnaces are backed by industry-leading R&D to ensure your process repeatability.

Ready to elevate your material engineering? Contact us today to discuss your unique needs!

Visual Guide

References

- Angadi Seshappa, Neelam Singh. Investigating the mechanical properties of al7075 metal matrix composite with improved performance through the incorporation of fe3o4 and RHS. DOI: 10.1051/matecconf/202439201025

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does electromagnetic stirring in IGBT induction melting furnaces improve melt quality? Achieve Superior Metal Purity and Homogeneity

- How does IGBT enhance efficiency and energy savings in induction melting? Achieve Superior Control and Lower Costs

- What role does vacuum induction melting equipment play in the preparation of CrFeNi alloys? Essential Purity Guide

- Why are argon (Ar) and sulfur hexafluoride (SF6) introduced during magnesium alloy melting? Protect Your Melt Quality

- Why is a Vacuum Induction Melting furnace (VIM) used for Cu-Zn-Al-Sn alloys? Achieve Precision Composition Control

- Why is a vacuum environment important in a VIM furnace? Unlock Purity and Performance in Metal Melting

- Why is multiple vacuum remelting necessary for Ti-33Mo-0.2C? Solve High-Moly Segregation Challenges

- Why are Water Cooled Copper Pots utilized during the melting process of titanium alloys? Ensure Purity with Skull Melting